- Jul 21, 2013

- 52,508

- Pool Size

- 35000

- Surface

- Plaster

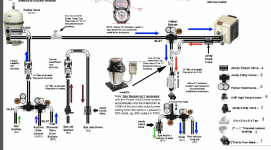

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

So day 1 install hydrazzo... day 2 come back polish and fill pool... and the startup process begins?

yup, I brought in four water trucks to quickly fill my pool after the polishing was complete.

Then it is normal plaster startup process.