- May 3, 2007

- 18,073

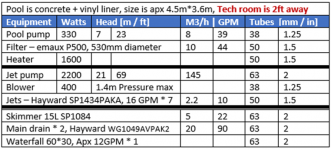

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

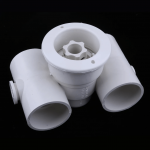

Fiberglass stand alone spas are a separate entity and nearly impossible to replicate in concrete. If that is what you want, you should buy because you will never be able to replicate one in concrete. At least not very easily.2. Wouldn't it make some nice Fountain-ISH feel/look for the corner there ?Big-OLL nice bubbles popping up from the bottom of the seat there...

When you sit in a hot-tub... those pre-made ones ... there are holes all over the place....

I just checked again and it seems like you are 100% right ... There are no jets up your Rear in these ... HuH?! and their thigh jets and on bent legs...

The bubbles from the spa walls will look just the same as if it was in the floor. You wont be able to tell the difference. Have you seen a normal gunite spa in operation. There are bubble everywhere.

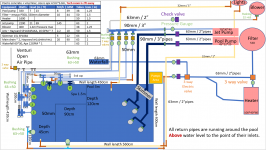

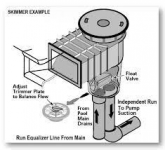

The Jandy manual I posted gives you instructions on how to determine blower size for air bubblers.Will my bubbler be enough for just 2 bubblers there? it'll be 4 meters