I'm making my own DIY pool nowadays, got my hole ready and all the ground is ready for cement pouring but i'm stuck with the whole plumbing!!!

1. Which pipes size should I use?

2. Which jets would work for the spa area and how many can work with my pumps?

My pump details:

Are these OK: Mumusuki 1.5in Outdoor Swimming Pool SP-1434 Massage Pool Spa Massage Nozzle Accessory

Or these: Swimming Pool Massage Nozzle - Swimming Pool Nozzle Adjustable Massage Jet Water Outlet Bathtub Nozzle Pool Accessories

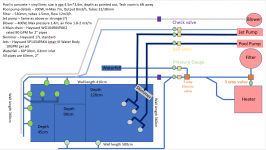

I've attached a scheme of how I Plan to do the plumbing, if anyone has any ideas I would love to hear that!

Please help me! Thanks!

1. Which pipes size should I use?

2. Which jets would work for the spa area and how many can work with my pumps?

My pump details:

Jets:HZS-300

Max flow: 9M³/H

Max Lift: 7M

Voltage: 220V-240V/50HZ

Power: 300 W

Outlet Size: 40 MM

Are these OK: Mumusuki 1.5in Outdoor Swimming Pool SP-1434 Massage Pool Spa Massage Nozzle Accessory

Or these: Swimming Pool Massage Nozzle - Swimming Pool Nozzle Adjustable Massage Jet Water Outlet Bathtub Nozzle Pool Accessories

I've attached a scheme of how I Plan to do the plumbing, if anyone has any ideas I would love to hear that!

Please help me! Thanks!