Hello,

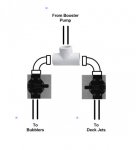

I am having a new pool put in and will have a booster pump shared between two water features (bubblers and deck jets). I will have an IntelliCenter for automation and an IntelliValve on the booster pump return. Is it possible to setup 3 "features" with this setup?

1. bubble only

2. deck jets only

3. both bubblers and deck jets

The builder doesn't think this is possible or doesn't know how to set it up considering the IntelliCenter is so new. Any ideas? I can't really find any useful info in the user guide and the online demo is locked down so you can't test adding new feature circuits.

Thanks,

Matt

I am having a new pool put in and will have a booster pump shared between two water features (bubblers and deck jets). I will have an IntelliCenter for automation and an IntelliValve on the booster pump return. Is it possible to setup 3 "features" with this setup?

1. bubble only

2. deck jets only

3. both bubblers and deck jets

The builder doesn't think this is possible or doesn't know how to set it up considering the IntelliCenter is so new. Any ideas? I can't really find any useful info in the user guide and the online demo is locked down so you can't test adding new feature circuits.

Thanks,

Matt