Hi all - I am converting to a SWCG and per the advice from the great folks on this site I am staying with Pentair due to the automation and remote capabilities possible integrating with my existing ET controller w/ScreenLogic2. I have an iChlor SWCG with the additional Intellichlor power center on the way arriving tomorrow and have questions regarding the install if I go the DIY route (which I've been told is fairly straight forward, both plumbing and electrical). The only hesitancy I have with a DIY install is if I could possibly qualify for the extended warranty with Pentair by having a pro install the SWCG along with a new filter, MPV, and valve actuator (all Pentair). Not sure if the MPV and actuator qualify as an additional (3rd) piece of equipment for that purpose.

If I do install myself, I searched TFP and Google for installation steps, pictures/videos, specifically for integrating with an existing ET system. I imagine some exist, but I could not find what I am looking for in the weeds, and most online videos show connecting the power center to a standard timer box.

Questions:

Thanks!

If I do install myself, I searched TFP and Google for installation steps, pictures/videos, specifically for integrating with an existing ET system. I imagine some exist, but I could not find what I am looking for in the weeds, and most online videos show connecting the power center to a standard timer box.

Questions:

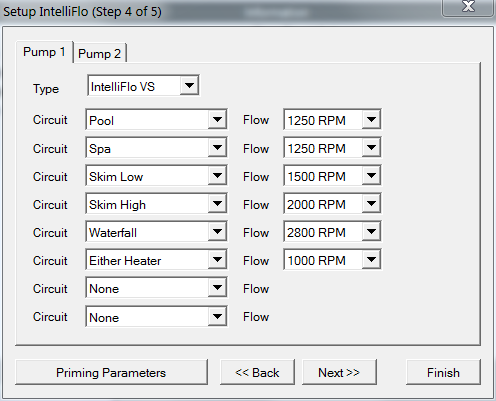

- Beyond the manual (which I've read) is there a published schematic, photos, or steps to hook up the power center to an existing ET including connectivity of the communication cable (RS-485) when I believe there is already one connected from my IntelliFlo VS pump to the ET comm input.

- Related to above, if there is only 1 comm input on the standard ET8 system, will I need to pigtail the two RS-485 cables or is there enough room to connect both sets of cables into the same comm port?

- Other than an additional copper wire and screw nut for bonding to my system, are there any other parts I need to pick up from the store to complete the electrical install of the power center such as to wire the power from the ET pump relay to the Intellichlor power center? If so, what type and gauge wire? Do I get a few feet of each from the hardware store? Presume I'll want some flexible conduit and male/female ends to connect to each box.

- Plumbing: my existing plumbing is attached below with a couple of options I've come up with so far. I do not see much value/point in Opt 1 as there will be no need for the tab feeder (and thus the check valve). I have marked both options up with a vertical install as that is what is recommended in Pentair's manual for "optimal performance" of the cell. Otherwise I would go with a straight horizontal install assuming I have sufficient room for a 12" straight pipe prior to the cell and before the "T" to my returns, but alas I don't think I'd have room. The valve on the vertical line after the tab feeder is my spa return line which will be having an actuator installed so I can control my spillway. Any alternative suggestions or concerns with the plumbing plan as depicted?

Thanks!