David,

Welcome aboard!

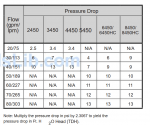

We need some more information. Can you please add photo of the entire equipment pad and of the piping and valve changes. Once you do that can you please add equipment and model numbers to your "signature". 10 psi doesn't seem way to high. My pool with similar equipment ran about 18 psi. The expected pressure drop would be the sum of the pressure drops of the equipment added. We need to know the flow rate to check and for that we need your pump model plus the drop of the other items added. I've added the pressure drop table for your heater below. If you have 50 gpm flow the drop in the heater could be 10 psi. The table appears to be in psi based on the note but isn't completely clear.

To add a "signature" click on your screen name above right and select "signature". A box will open that will allow you to type it in. Please don't forget to press SAVE. Add things like pool type, size, equipment and model numbers plus anything unique about your pool.

I hope this helps.

Chris

View attachment 98148