Hi, I’m new to this forum and I’m trying to figure out why my heat exchanger on my Raypak for both pool and spa are going out or bad after a years use having condensation run down the stacks and into the unit!!????

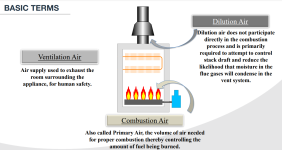

The heat exchanger are not chemically damaging themselves from the inside out. They’re being damaged and corroded acidic corrosion from the outside in causing Pine holes, and the condensation runs down the chimney stack out over the hood and down into the units, causing the flame and corrosion to not combust properly how to fix this please somebody Help me to fix this issue.

The heat exchanger are not chemically damaging themselves from the inside out. They’re being damaged and corroded acidic corrosion from the outside in causing Pine holes, and the condensation runs down the chimney stack out over the hood and down into the units, causing the flame and corrosion to not combust properly how to fix this please somebody Help me to fix this issue.