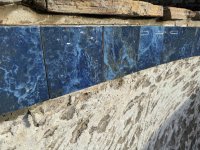

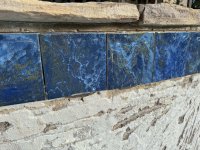

Per tile guy- half tiles couldn't be avoided. We ended up with two half tiles in one spot and in another. Guy said he'd need to measure perfectly to not have this happen, and that it's really difficult due to the curves in the pool. For the small enclave by the seat, I don't know if it could be avoided, he says that he'd have to do large grout lines which wouldn't be ideal and would be more likely to have water intrusion (using spectralock epoxy though).

Any opinions on this?

Any opinions on this?