Is the breaker arc fault as well as ground fault?

When the contacts for the heater close, the high amperage can and will cause arcing, which can trip an arc fault breaker.

If the breaker is arc fault and an arc fault breaker is not required by code, you might want to replace the breaker with a non arc fault model.

The breaker specified is 60 amp GFCI, so that is what should be used.

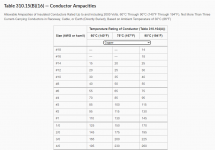

The Romex is only rated to 55 amps, so it is too small for a 60 amp breaker.

What is the make and model of the breaker?

When the contacts for the heater close, the high amperage can and will cause arcing, which can trip an arc fault breaker.

If the breaker is arc fault and an arc fault breaker is not required by code, you might want to replace the breaker with a non arc fault model.

The breaker specified is 60 amp GFCI, so that is what should be used.

The Romex is only rated to 55 amps, so it is too small for a 60 amp breaker.

What is the make and model of the breaker?

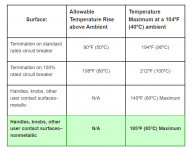

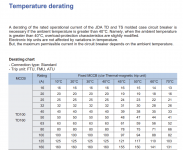

Expected heat rise in normal applications.

This section discusses the expected temperature rise we encounter on the cover of the panel or the handle of the circuit breaker.

The line terminal or bus bars, as called out above, will not be discussed.

A panel full of non-electronic, standard thermal-magnetic circuit breakers running a heavy load—for instance, above 50% the rating for the main circuit breaker protecting the panel, or 100 A in a 200 A service—is expected to rise 15 °C (27 °F) above ambient temperature.

Eaton AFCI circuit breakers consume less than 1 watt to power up the electronics within the breaker. This additional power consumption, above the contribution from the mechanical components mentioned above, can add another 5–10 °C (9–18 °F) of heat rise above ambient for the system.

Eaton AF/GF circuit breakers consume slightly more than 1 watt to power up their internal electronic components. A panel full of AF/GF breakers might rise 10–20 °C (18–36 °F) above ambient.

Given a typical mix of circuit breakers and typical consumption, we expect a 25–30 °C (40–54 °F) heat rise on the hottest part of the exposed panel cover above the ambient temperature.

In a 38 °C (100 °F) garage, it would not be surprising, nor would it be unsafe, to see a panel as warm as 65 °C (150 °F).

As demonstrated above, the materials of the circuit breakers are designed and tested to function in much higher temperatures than 65 °C (150 °F).

Last edited: