Fantastic! Thanks for reaching out to them. I'll wait to hear back from you.That pump is old. The new intelliflo3 pumps have an optional relay board that can control the SWG. Cannot get that for this pump.

44/60 doesn't matter. They use the same energy. Can be run 115v.

I'll call @ajw22 and @Jimrahbe again and try to have them weigh in on the easy touch IC integration. Like to get that before you commit to RJ.

FC and CYA - Justifying the increased cost of Liquid Chlorine

- Thread starter ibondsmith

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

i,I only have 110v, will that be an issue?

Are you sure???

I'm pretty sure the pump that you have only runs off of 240 Volts AC..

If you have an EasyTouch, show me pics of your pump/filter relay in the upper left of your cabinet.. Show two pics, one of the just the relay and one showing all your circuit breakers.

Thanks,,

Jim R.

Not sure of the voltage actually. Just moved into this house.Are you sure???

I'm pretty sure the pump that you have only runs off of 240 Volts AC..

Hopefully these are the pics you are looking for.Show two pics, one of the just the relay and one showing all your circuit breakers.

Attachments

i,

The input to your EasyTouch looks to be 240 Volts AC..

And I suspect that the very bottom breaker feeds your IntelliFlo pump..

But it does not appear to me that you have any 240 volt breakers.. I am not sure about the bottom two (4) breakers, as I have not seen that style before.. I suspect they feed the IntelliFlo, but they are only 15 amps and normally the IntelliFlo is wired to a 20 amp breaker.

Can you tell if the 2nd conduit from the left goes to the IntelliFlo??

In general, if you have an EasyTouch system, you would need a Pentair IntelliChlor IC40 salt system, so that you could use the EasyTouch to control the SWCG and to display the salt reading from the cell.. You can use any SWCG system you want, but then the EasyTouch would only be able to turn it on or off.

Since your EasyTouch did not come with an internal SWCG power supply, you would have to buy a complete Salt system.. This would include a Power Center and the cell itself.

If you want your salt system to integrate with your EasyTouch, you will need the following..

If you don't care about the integration, then you are free to buy whatever SWCG system that floats your boat...

No matter what SWCG system you buy it will have to be connected to your pump/filter relay.. This relay in your EasyTouch is not being used now.. It will need to be connected to an input AC source (120 or 240 volts) and then the output of the relay connected to the SWCG system, which could be configured to accept either 120 or 240 volts..

Thanks,

Jim R.

The input to your EasyTouch looks to be 240 Volts AC..

And I suspect that the very bottom breaker feeds your IntelliFlo pump..

But it does not appear to me that you have any 240 volt breakers.. I am not sure about the bottom two (4) breakers, as I have not seen that style before.. I suspect they feed the IntelliFlo, but they are only 15 amps and normally the IntelliFlo is wired to a 20 amp breaker.

Can you tell if the 2nd conduit from the left goes to the IntelliFlo??

In general, if you have an EasyTouch system, you would need a Pentair IntelliChlor IC40 salt system, so that you could use the EasyTouch to control the SWCG and to display the salt reading from the cell.. You can use any SWCG system you want, but then the EasyTouch would only be able to turn it on or off.

Since your EasyTouch did not come with an internal SWCG power supply, you would have to buy a complete Salt system.. This would include a Power Center and the cell itself.

If you want your salt system to integrate with your EasyTouch, you will need the following..

If you don't care about the integration, then you are free to buy whatever SWCG system that floats your boat...

No matter what SWCG system you buy it will have to be connected to your pump/filter relay.. This relay in your EasyTouch is not being used now.. It will need to be connected to an input AC source (120 or 240 volts) and then the output of the relay connected to the SWCG system, which could be configured to accept either 120 or 240 volts..

Thanks,

Jim R.

2nd from left goes to the heater.I suspect they feed the IntelliFlo, but they are only 15 amps and normally the IntelliFlo is wired to a 20 amp breaker.

Can you tell if the 2nd conduit from the left goes to the IntelliFlo??

The pump is the rightmost conduit which it appears is 220 and, as you suspected, being fed by 15amp circuits, one on each of the bottom two double breakers.

It looks like the complete Pentair system and a Circupool RJ-45 would cost about the same amount - Around $1,500-$1,600. I like the additional life of the RJ-45 (15,000 hours vs. 10,000) and the 7 year warranty (albeit prorated after 2 years) is very attractive as compared to the 90 day warranty for the DIY install on the IC40.f you want your salt system to integrate with your EasyTouch, you will need the following..

Pentair IntelliChlor IC40 Complete Salt Chlorinator System

If you don't care about the integration, then you are free to buy whatever SWCG system that floats your boat...

Once I get the SWG unit dialed in, how much control do I need to have on a daily/weekly basis? Is having it integrated really that big of a deal?

Can you recommend a resource (video or TFP forum post) to help me through an install, including connection to the pump/filter relay. I am fairly handy but like to have someone double check my electrical work.No matter what SWCG system you buy it will have to be connected to your pump/filter relay..

Thanks for all the help!

Last edited:

i,

Having the SWCG integrated into the EasyTouch is slightly more important if you have some kind of remote inside the house.. If you have a remote, or ScreenLogic, it makes you lazy, as you can do it all from your couch..

If you have to go out the equipment pad to adjust things or change settings on the EasyTouch, it does not really matter what kind of SWCG you have.. as you are out there anyway..

We have a ton of people here that can help you with the install, no matter which way you go..

Note... You will probably get a lot of posts about your circuit breakers being the wrong type and not GFCI.. Which is all true, but I'm not the breaker police and I don't care what breakers you have... as long as you know they are not correct...

Thanks,

Jim R.

Having the SWCG integrated into the EasyTouch is slightly more important if you have some kind of remote inside the house.. If you have a remote, or ScreenLogic, it makes you lazy, as you can do it all from your couch..

If you have to go out the equipment pad to adjust things or change settings on the EasyTouch, it does not really matter what kind of SWCG you have.. as you are out there anyway..

We have a ton of people here that can help you with the install, no matter which way you go..

Note... You will probably get a lot of posts about your circuit breakers being the wrong type and not GFCI.. Which is all true, but I'm not the breaker police and I don't care what breakers you have... as long as you know they are not correct...

Thanks,

Jim R.

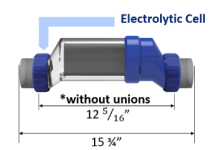

Update: I ordered the Circupool RJ-60. Discount Salt Pool was having a sale that made the 60 less expensive than the 45 (go figure), so I will have a unit that is way oversized for the 20k gallon pool. I figure that's not a bad thing as it will extend the life of the cell and not have my FC production needs dictate my pump time - although it will require me to run the pump at a high RPM than I have been (I'm told 1,800) when I need to generate FC.

The install seems fairly straight forward, although I will likely need some assistance with the pump/filter relay connection.

A few preliminary questions as I wait for delivery:

The install seems fairly straight forward, although I will likely need some assistance with the pump/filter relay connection.

A few preliminary questions as I wait for delivery:

- The only spot on my plumbing as it currently exists is on an upward slope of approximately 60 degrees. The folks at Discount Salt Pools say that a vertical installation is better than a horizontal one b/c gravity will insure the pipe is always full (even at slightly lower pump speeds) which will keep the flow sensor on so the unit can produce FC. Anyone see any issue with mounting on an upward slope, and does it make sense that I would get a similar gravitational benefit to a vertical installation?

- I know that SWGs don't produce FC fast enough for SLAM level, but with a 3x oversized system will I get close such that I can minimize my liquid chlorine use if I have to SLAM?

- Discount Salt Pools is suggesting that I get my phosphates to zero using PR 10,000. I have read a few posts here on TFP that essentially say not to worry about phosphates but instead focus on keeping FC at the proper levels. What are people's thoughts on Discount Salt Pool's statements that I should use PR 10,000 to get phosphates to zero?

- Jun 24, 2021

- 17,088

- Pool Size

- 29000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

Mine runs down to 6-700RPM. Every pool is different, but I'd be surprised you have to run that high.it will require me to run the pump at a high RPM than I have been (I'm told 1,800) when I need to generate FC.

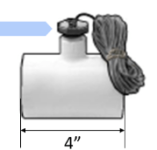

Can you post pictures of your pad before we weigh in...in general, you want your flow switch to be horizontal or best case on the up flow. I don't think it matters on the cell, but let's see what you have.

- The only spot on my plumbing as it currently exists is on an upward slope of approximately 60 degrees. The folks at Discount Salt Pools say that a vertical installation is better than a horizontal one b/c gravity will insure the pipe is always full (even at slightly lower pump speeds) which will keep the flow sensor on so the unit can produce FC. Anyone see any issue with mounting on an upward slope, and does it make sense that I would get a similar gravitational benefit to a vertical installation?

You can try, we don't recommend. We recommend you avoid algae altogether. My pool hasn't been slammed since I joined TFP. Link-->FC/CYA Levels

- I know that SWGs don't produce FC fast enough for SLAM level, but with a 3x oversized system will I get close such that I can minimize my liquid chlorine use if I have to SLAM?

Ignore phosphates and maintain proper FC for your CYA.

- Discount Salt Pools is suggesting that I get my phosphates to zero using PR 10,000. I have read a few posts here on TFP that essentially say not to worry about phosphates but instead focus on keeping FC at the proper levels. What are people's thoughts on Discount Salt Pool's statements that I should use PR 10,000 to get phosphates to zero?

Can you post pictures of your pad before we weigh in...in general, you want your flow switch to be horizontal or best case on the up flow. I don't think it matters on the cell, but let's see what you have.

Great to know. I'll experiment with lower speeds.Mine runs down to 6-700RPM. Every pool is different, but I'd be surprised you have to run that high.

Attachments

- Feb 6, 2015

- 7,949

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

Your signature indicates you use "test strips/Leslie's testing".

Is that still the case?

If not, update your signature

If so, you really need your own test kit to test the pool water yourself.

Test Kits Compared

The TF-Pro Salt will have all the items needed to easily test your pool water.

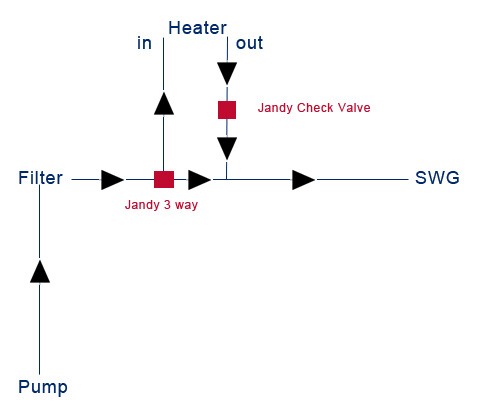

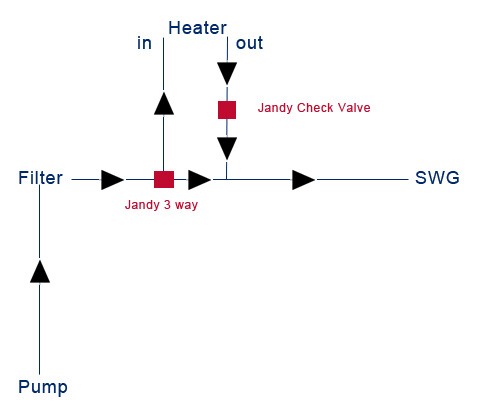

You will be better served by installing a heater bypass. This will allow running the pump at a lower speed when the heater is not needed. The SWG requires a certain flow (every pool is different) to satisfy the SWG flow switch. The heater restricts that flow and requires a higher pump RPM to produce the same flow as when the heater is bypassed.

www.troublefreepool.com

www.troublefreepool.com

Is that still the case?

If not, update your signature

If so, you really need your own test kit to test the pool water yourself.

Test Kits Compared

The TF-Pro Salt will have all the items needed to easily test your pool water.

You will be better served by installing a heater bypass. This will allow running the pump at a lower speed when the heater is not needed. The SWG requires a certain flow (every pool is different) to satisfy the SWG flow switch. The heater restricts that flow and requires a higher pump RPM to produce the same flow as when the heater is bypassed.

Heater Bypass - Further Reading

Just ordered my TF Pro Salt.

Thank you for the information on the heater bypass. I see the value in the bypass, but I am not looking to invest in a lot of changes beyond the purchase of the SWG unless it's absolutely necessary, or if I will somehow recoup the cost in the next few years. I am in a temporary rental home (3-4 years) having been displaced by the California wild fires earlier this year. I got the SWG because I was/am convinced that it will pay for itself in liquid chlorine and time/hassle savings.

Do you think the SWG and flow switch will work on the 60 degree incline? PoolStored, you seemed to think the cell would be fine but maybe not the flow switch. Would there be an issue with installing the flow switch on the relatively horizontal pipe leading into the heater? Just a thought.

One somewhat related question...

Now that I'm converting to a SWG I understand that I will need to raise my CYA. It is currently at 50. This is admittedly a Leslies measurement corroborated by test strips, but I don't have my test kit yet. If I do indeed need to raise the CYA, would using the pucks I purchased before finding TFP be an ok way to do that. I now know that stabilized chlorine is no good for regular use, but I do have a big bucket of pucks sitting around.

Thanks.

P.S. I have plenty of fodder for my PoolStored entry, which I will post after I have installed the SWG and my pool is running smoothly - fingers crossed!

Thank you for the information on the heater bypass. I see the value in the bypass, but I am not looking to invest in a lot of changes beyond the purchase of the SWG unless it's absolutely necessary, or if I will somehow recoup the cost in the next few years. I am in a temporary rental home (3-4 years) having been displaced by the California wild fires earlier this year. I got the SWG because I was/am convinced that it will pay for itself in liquid chlorine and time/hassle savings.

Do you think the SWG and flow switch will work on the 60 degree incline? PoolStored, you seemed to think the cell would be fine but maybe not the flow switch. Would there be an issue with installing the flow switch on the relatively horizontal pipe leading into the heater? Just a thought.

One somewhat related question...

Now that I'm converting to a SWG I understand that I will need to raise my CYA. It is currently at 50. This is admittedly a Leslies measurement corroborated by test strips, but I don't have my test kit yet. If I do indeed need to raise the CYA, would using the pucks I purchased before finding TFP be an ok way to do that. I now know that stabilized chlorine is no good for regular use, but I do have a big bucket of pucks sitting around.

Thanks.

P.S. I have plenty of fodder for my PoolStored entry, which I will post after I have installed the SWG and my pool is running smoothly - fingers crossed!

Last edited:

- Jun 24, 2021

- 17,088

- Pool Size

- 29000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

It *might* Heaters add a bit of head, and have a minimum flow rate. If you don't run the heater, and you can bypass the heater, you can run lower RPM.or if I will somehow recoup the cost in the next few years.

I think the incline is just fine, for cell and flow switch. You want 12" of straight before the flow switch, and the cell can count. I would go Heater --> incline-->cell-->flowswitch-->return.Do you think the SWG and flow switch will work on the 60 degree incline? PoolStored, you seemed to think the cell would be fine but maybe not the flow switch. Would there be an issue with installing the flow switch on the relatively horizontal pipe leading into the heater? Just a thought.

What is the distance between the two elbows on the proposed location (length of the straight 60 degree incline PVC pipe)?

Last edited:

- Apr 10, 2018

- 6,543

- Pool Size

- 18375

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

Good plan...Would there be an issue with installing the flow switch on the relatively horizontal pipe leading into the heater?

The flow switch should be on a horizontal with 6-12" of straight pipe before it. The cell can go on the incline. When you plan your plumbing, also make sure you can easily plumb it back together when you take cell

You got a good deal on the RJ60!

EDIT...look like @PoolStored posted just before me...

Last edited:

When you plan your plumbing, also make sure you can easily plumb it back together when you take cellThat means leaving enough PVC to install couplers before and after the unions.

25.5 inches.What is the distance between the two elbows on the proposed location (length of the straight 60 degree incline PVC pipe)?

From what I can tell a diverter and actuator will run around $250 (plus the cost of PVC couplers and pipe). Does that sound about right?It *might* Heaters add a bit of head, and have a minimum flow rate. If you don't run the heater, and you can bypass the heater, you can run lower RPM.

As far as RPMs generally, I am currently following the pump schedule that the former caretaker had set up: 3,450 RPM for 3 hours (vacuum speed) + 6 hours at 1,250 RPM. Does that seem like a reasonable schedule? Could I make a change to save some energy cost (which are really high in CA). Thanks!

- Jun 24, 2021

- 17,088

- Pool Size

- 29000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

Given how tight this is (limiting later modification) what do you think of the idea of putting the flow switch on the horizontal before the heater?Tight, but can be done.

- Jun 24, 2021

- 17,088

- Pool Size

- 29000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

Either will work! Might be easier to put the flow on the horizontal and cell on the 60 degree. You have lots to work with...Given how tight this is (limiting later modification) what do you think of the idea of putting the flow switch on the horizontal before the heater?

- Apr 10, 2018

- 6,543

- Pool Size

- 18375

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

...after the heater, yeah?Given how tight this is (limiting later modification) what do you think of the idea of putting the flow switch on the horizontal before the heater?