Results two years and two court dates later

- Thread starter klanel

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Aug 20, 2020

- 5,826

- Pool Size

- 27000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60

Can use food coloring or Home Depot sells a blue dye kit for plumbing leaks. I’ve never tried that though.What kind of dye? Process?

Process: (there’s a detailed method somewhere on this site)

1. find a very small syringe like they use for feeding newborns formula, or I used a generic syringe for dispensing small amounts of liquid.

2. Turn all all pumps or anything that makes the water move and squirt a tiny amount under water near where you think the leak is.

3. Watch what the dye does to see if it gets sucked towards anything. If it does, that indicates water is moving in that area.

A guy came out and did that to find a leak at both my skimmers.

Turbo1Ton

Gold Supporter

- Dec 26, 2019

- 1,839

- Pool Size

- 14500

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Here is a leak detection kit. This is the syringe I've seen used in the leak detection videos I've watched on youtube and other places.

--Jeff

Does anyone know what type of fitting is used for the LED conduit termination in the spa wall? I currently have an 1-1/2" PVC male which is capped for a plug. And I recently wrapped a butyl rubber product around the connector base to act as a washer. It still dropped about 3/4" overnight. What I would like to do is pressurize the conduit to see if it will hold air and make sure it is not coming out around the LED conduit fitting. I spoke with the concrete contractor and he says they repaired the broken conduit before they poured. Does anyone know how much pressure would be appropriate for testing this conduit? I want at least as much pressure as it would have with the water weight. Same with the drains if it comes to that. What type of fitting, is it threaded or just a base plate glued on with a cover?

- Jul 21, 2013

- 53,181

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

The LED light wire conduit will be open on the other end where it comes out at the junction box. So how will you pressurize the conduit with one end open?

I capped and glued the end at the equip pad. It had water coming from the top due to low elevation so that was sealed off 2 months ago. I will have to remove cap and install a pressure gauge/valve/air fitting.The LED light wire conduit will be open on the other end where it comes out at the junction box. So how will you pressurize the conduit with one end open?

Pic below taken when I saw seepage on the deck and just prior to capping.

Still have a spa leak and other issues but the plumber is running electrical to and from the OmniPL control. I had asked if he was using GFCI breakers and he asked if that is what I wanted. My response was that I want it to meet code and that I would think that GFCI breakers would be required for any equipment in contact with the water.

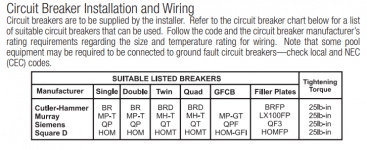

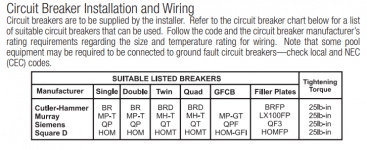

So, I have looked over the Hayward OmniPL manual and it has a list of suitable breakers and as for GFCI, to refer to local codes. None of the breakers used are on the list of mfg's. All the breakers are of the right BR type except the one for the heatpump which is neither listed for manufacturer or type.

What can someone tell me? My current thought is why a plumber is doing electrical without a license?

So, I have looked over the Hayward OmniPL manual and it has a list of suitable breakers and as for GFCI, to refer to local codes. None of the breakers used are on the list of mfg's. All the breakers are of the right BR type except the one for the heatpump which is neither listed for manufacturer or type.

What can someone tell me? My current thought is why a plumber is doing electrical without a license?

- Jul 21, 2013

- 53,181

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

None of those breakers are GFCI.

Pumps and SWG need to be GFCI breakers. HP does not need to be GFCI. Pool lights should be on a GFCI either through a breaker or on the LOAD side of a GFCI outlet.

If the guy is a plumber and is not aware of what the NEC is I would check that proper wire sizes are being used.

License requirements depend on your local jurisdiction.

Pumps and SWG need to be GFCI breakers. HP does not need to be GFCI. Pool lights should be on a GFCI either through a breaker or on the LOAD side of a GFCI outlet.

If the guy is a plumber and is not aware of what the NEC is I would check that proper wire sizes are being used.

License requirements depend on your local jurisdiction.

The county will allow a homeowner to do their own wiring. However, if a contractor is used, they are required to be licensed electricians. If the plumber is asking me about if I want GFCI breakers, it would lead me to believe that he is not licensed for electrical. The builder could be letting the county think I am wiring it or someone could be signing off on it later.License requirements depend on your local jurisdiction.

I would suspect that a GFCI would be required by the NEC. As for wire size, he ran a THNN cable with (2) - 6 awg conductor and a 10awg ground for use at a 100a service. The max ampacity I see is 75 amps. This is in conduit which would decrease that but I will get the official word before I tell them it has to be changed out. And will see what is required by code for the breakers.

- Aug 20, 2020

- 5,826

- Pool Size

- 27000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60

I want it to code and don't believe this would be. I have a 4 wire subpanel they tied to with a two conductor w/ ground cable. I know the cable gauge is too small for 100 amp but am questioning if 3 wires are correct as well. This is what happens when you have a plumber doing electrical. It will be corrected before it's over with.,FWIW, none of the breakers in my panel as GFCI, but it’s 20 years old.

tommelton

Silver Supporter

My feed from home breaker panel to the Hayward panel, is 4 wire, white, red, black and bare ground. Is only 3 wires entering your panel? Do you have pictures on the supply termination in the Hayward panel?

- Jul 21, 2013

- 53,181

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Two hot wires plus ground gives you only 240 volt service in the panel.

You need a white neutral line to have 120 volts for thing like lights and outlets.

You need a white neutral line to have 120 volts for thing like lights and outlets.

tommelton

Silver Supporter

Or 3 wires give you 120 volt only, one hot, one neutral and ground. I asked Klanel in a PM for a pic of his panel insides.Two hot wires plus ground gives you only 240 volt service in the panel.

You need a white neutral line to have 120 volts for thing like lights and outlets.

- Jul 21, 2013

- 53,181

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Or 3 wires give you 120 volt only, one hot, one neutral and ground. I asked Klanel in a PM for a pic of his panel insides.

It would be incompetence to be wiring up a new pool panel and pump with only 120 Volts.

They are running 240, my guess is they will not connect the ground and will wire it as a legacy 3 wire, two hots one neutral. Will see and post pics after they finish their masterpiece

The plumber/electrician/pool expert finished wiring the OmniPL today. He had the control set for the spa to spillover anytime the control was in the pool mode.

Said I have two options:

Pool mode (spillover constant, drains closed, pool and spa returns open)

Spa mode (spillover off, spa returns on, pool returns off, spa drain open)

I told him having the spillover constant when in pool mode was unacceptable. I did not want to listen to the noise 24/7 and it raises the PH. He says he's been in the pool business for 20 years and he's never heard such about aeration raising the PH. Also says 100 percent of pools with spas spillover all the time. I told him the first pool the builder showed us had the spa off and the bubblers were running on the sunshelf.

So my question is, I have a three way valve that I want to be able to operate 180 degrees from spa returns closed to pool returns closed and variable in between. He says that is impossible. So for now, I manually flip the toggle switch to do what I want but there should be a better way. This is important enough for me to get rid of valve automation.

Another known issue, the blower does not come on when set on with the display. I can hear a relay click but nothing happens. I turned on the booster pump and that works.

Pictures below show the wiring, the equip pad, and a conduit strap he left hanging that says "the plumber was here". PVC glue was spilled on the kool deck and left and he was going to take the heat pump anchoring straps with him. I had them left so the builder can put them on so some strong winds doesn't rip it up from where it's sitting.

Salt cell installed but no one has added salt. The picture of where my fingers are holding the two black wires are where the blower is connected to the relay. Have not looked at the manual to see if this is wired correctly or if it is programmed for the correct relay. The plumber seemed to be in a hurry to get out of here.

The wire gauge from panel to control is not rated for 100 amps and the cable type is not for this application per code.

Said I have two options:

Pool mode (spillover constant, drains closed, pool and spa returns open)

Spa mode (spillover off, spa returns on, pool returns off, spa drain open)

I told him having the spillover constant when in pool mode was unacceptable. I did not want to listen to the noise 24/7 and it raises the PH. He says he's been in the pool business for 20 years and he's never heard such about aeration raising the PH. Also says 100 percent of pools with spas spillover all the time. I told him the first pool the builder showed us had the spa off and the bubblers were running on the sunshelf.

So my question is, I have a three way valve that I want to be able to operate 180 degrees from spa returns closed to pool returns closed and variable in between. He says that is impossible. So for now, I manually flip the toggle switch to do what I want but there should be a better way. This is important enough for me to get rid of valve automation.

Another known issue, the blower does not come on when set on with the display. I can hear a relay click but nothing happens. I turned on the booster pump and that works.

Pictures below show the wiring, the equip pad, and a conduit strap he left hanging that says "the plumber was here". PVC glue was spilled on the kool deck and left and he was going to take the heat pump anchoring straps with him. I had them left so the builder can put them on so some strong winds doesn't rip it up from where it's sitting.

Salt cell installed but no one has added salt. The picture of where my fingers are holding the two black wires are where the blower is connected to the relay. Have not looked at the manual to see if this is wired correctly or if it is programmed for the correct relay. The plumber seemed to be in a hurry to get out of here.

The wire gauge from panel to control is not rated for 100 amps and the cable type is not for this application per code.

- Jul 21, 2013

- 53,181

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Here is the way SPILLOVER gets enabled in the OmniLogic. Should be something similar in th OmniPL Manual..

www.troublefreepool.com

www.troublefreepool.com

There is a bare copper wire coming though the hole as the 3 wire feed and connected to the ground bar. I hope it goes back to the ground bar on your main electrical panel and not to your bonding wire.

Hayward OmniLogic - Further Reading

There is a bare copper wire coming though the hole as the 3 wire feed and connected to the ground bar. I hope it goes back to the ground bar on your main electrical panel and not to your bonding wire.

I briefly read over this and it does exactly what I have been doing manually. Turning on the spa a couple times/day to refresh the water. The plumber said the controller has no way to control the 3 way valves with the actuator I have. Went on to say Hayward does not make an actuator that will do what I want to do. That he can't go the full 180 degrees but can only move it 90 degrees. So his plan was to have both returns on all the time and when you went 90 degrees it would shut off the pool returns and turn the spa returns on max.Here is the way SPILLOVER gets enabled in the OmniLogic. Should be something similar in th OmniPL Manual..

Do you know if to do this is merely a programming issue, do I need some other type of actuator or does the plumbing need to be done differently? I want them to fix but need to know what is possible. The actuator is a Hayward GVA-24

I will look at it closer tomorrow and let you know.There is a bare copper wire coming though the hole as the 3 wire feed and connected to the ground bar. I hope it goes back to the ground bar on your main electrical panel and not to your bonding wire.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.