Also.... I took some video of the flow meters on the indoor and the outdoor pool. I will post them shortly. The outdoor pool flow meter has air at the top and I see an air bubble inside it. The indoor pool flow meter has no air in it. That air in the outdoor pool flow meter has to be addressed, right? That can't be right.

Backwash procedure for pool with 2 filters

- Thread starter JPMorgan

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- May 3, 2007

- 18,185

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

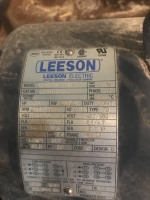

Same load/slip curves apply to single vs 3-phase induction motors. The slip would have to change to slow down the motor and that has significant consequences.It's a three phase motor, so it might be a problem in the motor.

No, not hard but I just don't see how it can be possible without other symptoms.I would want to verify to eliminate it as an issue.

Not that hard to check.

Maybe the controller is putting out 50 hz instead of 60 hz?No, not hard but I just don't see how it can be possible without other symptoms.

I would want to verify.

Here are videos of those flow meters...

Outdoor Pool

https://youtube.com/shorts/I3rV3RPiXDM?feature=shar

Indoor Pool

Outdoor Pool

https://youtube.com/shorts/I3rV3RPiXDM?feature=shar

Indoor Pool

Last edited:

- May 3, 2007

- 18,185

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Maybe the controller is putting out 50 hz instead of 60 hz?

I would want to verify.

Controller? Is this run off a VFD? I thought it was a direct power company connection.

- May 3, 2007

- 18,185

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

That should not affect the flow rate measurement because the air is trapped in the upper portion away from the paddle.

JPMorgan said Controller earlier.Controller? Is this run off a VFD?

Can you show the controller for the pump?

Are we talking about the pump here? What is a VFD? I'm not at all familiar with what you are referring to here.Controller? Is this run off a VFD? I thought it was a direct power company connection.

I was referring to the Controller that was installed last year to automate acid and chlorine feed to the pool... nothing related to the motor.JPMorgan said Controller earlier.

Ok, in any case, I would check the RPM even if it is an unlikely problem.

A noncontact tachometer is not expensive and it is easy to use.

A noncontact tachometer is not expensive and it is easy to use.

Last edited:

- May 3, 2007

- 18,185

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

- May 3, 2007

- 18,185

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Perhaps the cheapest/easiest option is to use the power company's power meter but only if you can control all the loads on the meter so they are not turning on and off during the test. You can take a measurement from the meter with the pump off vs on and the difference is the pump wattage or ideally just turn everything off except for the pump. If it is an old type dial spinning meter, you can lookup the conversion factors for dial RPM into wattage.

Other than that you will need at least 2 1-phase power meters or a 3-phase power meter and use one of these methods:

Other than that you will need at least 2 1-phase power meters or a 3-phase power meter and use one of these methods:

- May 27, 2021

- 1,445

- Pool Size

- 17000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

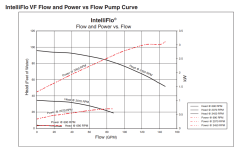

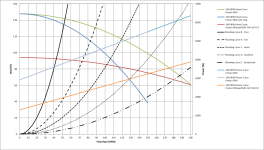

I just noticed the pump motor is dual rated for low voltage/high voltage. High voltage rpm is 3500….low voltage rpm is 2920. All the pump curves you’ve listed are for 3450….suppose the pump is wired for low voltage which would make it a 3HP pump running at 2920…..how does this affect the model?Here is an extrapolation based upon the pump's head curve and efficiency of pumps in that size range. It shouldn't be too far off.

View attachment 649432

- May 3, 2007

- 18,185

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

180v line to line is not typically used in the US but if they did, the flow rate would be reduced by 1-2920/3450 ~15% which really is not enough to go from 175 GPM to 120 GPM.I just noticed the pump motor is dual rated for low voltage/high voltage. High voltage rpm is 3500….low voltage rpm is 2920. All the pump curves you’ve listed are for 3450….suppose the pump is wired for low voltage which would make it a 3HP pump running at 2920…..how does this affect the model?

Most non-industrial 3-phase systems are 208v line to line but 230v is also used in certain applications. It is very easy to test this to make sure. Although you could also just look at the wiring.

Three-phase electric power - Wikipedia

I just noticed the pump motor is dual rated for low voltage/high voltage. High voltage rpm is 3500….low voltage rpm is 2920. All the pump curves you’ve listed are for 3450….suppose the pump is wired for low voltage which would make it a 3HP pump running at 2920…..how does this affect the model?

High Voltage 460/380The pump can take 50 Hz power or 60 Hz power and that might explain the difference.

The higher frequency will create a higher speed.

If the 60 Hz speed is 3,500 RPM (60 hz = 60 cycles per second and that is 3,600 RPM synchronous speed. The 3,500 RPM is due to "Slip").

3,500 RPM x 50/60 = 2,917 RPM.

So, the difference is the frequency.

The slower speed uses less power.

The power looks like 3.7Kw (5 HP = 3.7 Kw) and 2.24Kw (3 HP = 2.21 Kw).

It looks like the speeds are 3,500 RPM and 2920 RPM.

P1/P2 = N1^3/N2^3

N2^3 = (N1^3)(P2)/P1

N2 = cuberoot((N1^3)(P2)/(P1))

P2 = (P1)(N2^3)/N1^3

Using the affinity law, the second speed comes out to about 2960 RPM, so that seems likely.

P1 = 3,700 watts.

P2 = 2,240 watts

N1 = 3,500 RPM

N2 = cube root((N1^3)(P2)/(P1))

N2 = cube root((3500^3)(2240)/(3700))

N2 = 2960.85

If the flow is 195 at 3,500 RPM, then the flow should be about 163 GPM at 2,920 RPM.

If we use 2920 as the starting RPM, the higher RPM should be about 3,450 RPM, which is typical of a single speed pump.

If the flow is 130 at 2920 RPM, then the flow should be about 156 GPM at 3,500 RPM.

I suspect that the motor is wired for the lower speed and that changes the performance curve to look more like a 3 HP pump.

- May 3, 2007

- 18,185

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)