- Aug 12, 2015

- 79

- Pool Size

- 15009

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Jandy Aquapure 1400

Definitely a returnNo I’m not sure. If not a return, what else could it be?

Definitely a returnNo I’m not sure. If not a return, what else could it be?

Ok I flipped the waterfall valve to off. Prior to turning off and having only the waterfall pump on, water comes out of the return. Once I turned the valve to waterfall to the off position, a TON more water pressure comes through that same wall return.I’m going to go out today when the sun is up and turn the valve as James W suggested and I will report back.

The return pushes water through when the water feature pump is running. When the valve to the waterfall is off and pump still running, the water pressure coming through the return is much greater. When the main pump is on and waterfall pump is off, nothing comes through the return.The suction drains on the wall are for the waterfall and that other return pipe. It does not go through a filter so they put the suction on the wall to minimize picking up any debris. It seem strange that you have 3. Take a photo as they should be in a group.

You should have 2 main drains on the floor (or it could be a channel drain which looks like a single drain). take a photo of the bottom drain.

One idea - turn off your main filter pump - so there is no confusion on what is pushing water to the pool.

Then turn on the water feature pump = then as indicated by others - close the valve to waterfall and then find where that other return is coming out. Then turn the valve and that return should shut off and the waterfall should flow.

I have not seen the install instructions for the Aquapure, but I’m guessing it may still have to be replumbed unless Jandy says it’s ok to install on same return as IFCS?I do not see that IFCS limitation in the Jandy Aquapure manual.

The TruClear cell is undersized for your 18,500 pool.

You should have your PB replace it with an Aquapure 1400 cell. The Aquapure is a more robust cell that can take the pressure.

On that 2nd pump - it has 2 lines = one says waterfall and other says returns - where does the returns line go into the pool?

I suspect that a lot of these SWG’s are installed like mine are , which is on the same return as the IFCS. When I first brought this to the PB’s attention via text, his response was “I don’t foresee an issue because we do them all like that, and a lot of what we do here (FL) is not necessarily the same as the manual, but I’m going to reach out to the local Jandy Rep.”Reading thru this I think my PB installed my SWG wrong too, grrrr. I have the Pentair IC60 and this is how that manual shows installation should be...should have a bypass loop...I wonder if that would work with yours? My PB will be hearing from me on Monday, lol.

View attachment 433601

I bet money that when I contact the PB his response will be, "That's how we always do it." I haven't paid the PB in full yet b/c there are still open items (we're over 1 year) so I'll just add this to the list lol. I would think I could do it myself but I'd rather be a PIA and get them to do itI suspect that a lot of these SWG’s are installed like mine are , which is on the same return as the IFCS. When I first brought this to the PB’s attention via text, his response was “I don’t foresee an issue because we do them all like that, and a lot of what we do here (FL) is not necessarily the same as the manual, but I’m going to reach out to the local Jandy Rep.

The wall return on the waterfall line is to prevent deadheading the pump if the waterfall valve is closed while the pump is running. And to vent the excess flow from the pump if the waterfall valve is partially closed.Ok I flipped the waterfall valve to off. Prior to turning off and having only the waterfall pump on, water comes out of the return. Once I turned the valve to waterfall to the off position, a TON more water pressure comes through that same wall return.

I have T seen the install instructions for the Aquapure, but I’m guessing it may still have to be replumbed unless Jandy says it’s ok to install on same return as IFCS?

The return pushes water through when the water feature pump is running. When the valve to the waterfall is off and pump still running, the water pressure coming through the return is much greater. When the main pump is on and waterfall pump is off, nothing comes through the return

Well that’s not encouraging. Lol. I expect that the very least, the local Jandy rep that the PB mentioned will weigh in. I was hoping for an answer in writing from Fluidra stating it can’t be installed on the same line because it gives me some leverage should the PB continue to say they do them all this way.The Aquapure manual has no such limitations.

Who is Mr. Jandy you expect to give you the ok? You will not get a consistent response from a corporation other then referring you to the Installation documents.

When I stated the “pump still running” when closing the valve, I mean the waterfall pump. Isn’t it dedicated?View attachment 433629

This method won't work because too much flow will go to the cell and the IFC won't work.

View attachment 433631

This can possibly work because you can control the flow to the cell return, but this reduces the performance of the IFC and if you close the valve to the cell line, you might have the cell run with no flow and the cell can explode.

You can replace the impeller with a smaller impeller, which will reduce the performance of the IFC and it is still not consistent with the manual.

You can switch to the Aquapure and reduce the impeller.

The main pump should have been variable speed and the water feature pump should have been a dedicated water feature pump.

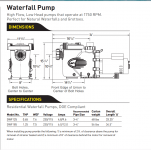

View attachment 433632

View attachment 433633

The PB is the Jandy reps customer, not you. The PB buys a lot of Jandy equipment from the rep. The rep is unlikely to throw the PB under the bus other then referring to the Installation Manual.Well that’s not encouraging. Lol. I expect that the very least, the local Jandy rep that the PB mentioned will weigh in.

I was hoping for an answer in writing from Fluidra stating it can’t be installed on the same line because it gives me some leverage should the PB continue to say they do them all this way.

All good points and I just said to my husband today earlier exactly what you said, that Jandy gets a lot of business from the PB and will not throw them under the bus. I’m not trying to do anything here but get this installation done properly and not have to come back years to come at my cost to continue replacing SWG’s that are installed improperly. If Fluidra refers back to the manual, which I expect they will, then the statement that the pool builder made “we have always done them this way” will be hard to defend. It’s the weekend and I haven’t heard back from the PB or Fluidra but I’m sure I will hear back one way or the other. The PB has had to fix some pretty serious issues on this build during the first 12 months and they faithfully have done so with no problem. We are in month 15 now though. The fact that the SWG was installed against manufacturer directions is leverage for me and I am hoping they will do what’s right and get it fixed properly. The more I know about what’s the best way to fix this, the better position I am in and I very much appreciate everyone’s input on this.The PB is the Jandy reps customer, not you. The PB buys a lot of Jandy equipment from the rep. The rep is unlikely to throw the PB under the bus other then referring to the Installation Manual.

Leverage with who, a Judge in a Court?

You have the answer in writing in the Installation Manual.

If the PB chooses to ignore the manufacturers directions who will force him to do something different?

Call them first thing on Monday and ask if they got your email and when you can expect a response.It’s the weekend and I haven’t heard back from the PB or Fluidra but I’m sure I will hear back one way or the other.

Agreed! This would be the best fix for the pool owner.I still think changing to the Aquapure cell is the easiest fix.

Oh don’t worry. Lol. I’ve had a lot of practice. In the first year we have had leak repair in the side main drain, divers to find it, drained the whole pool to uncover pop up heads covered by plasterers etc etc. I’ve had a ton of practice.Call them first thing on Monday and ask if they got your email and when you can expect a response.

How does the OP change the pump speed?The pump doesn't need to run at a higher rpm for 12 hours a day.