Jon

Your IntellipH maximum allowed dispersal rate only allows only one-minute-of-dispersal-per-hour which is 1/60th of the previous calculation: 1/60 * 45gpd = .75 gallons/day = 96 oz/day. This assumes that the IntellipH can run all 24 hours if your pump is running for all 24 hours. That’s an assumption that is not clear in the manual. Can the IntellipH run for all 24 hours, or is it limited to the 8-hours/day that is illustrated (but not specified) in the manual?

Check.. So to answer your question, the answer is YES, but with other factors to consider. As you pointed out, the intellipH delivers/doses/dispenses acid every hour. The amount of acid "delivered" is determined by a percentage number, determined and manually set by the user at the ipH controller. 0% = 0 amount of acid dispensed (essentially no run time of the P. pump), all the way up to 100% = 60 seconds of acid dispensed every hour.

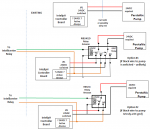

So, this occurs by use of an internal digital timer in the ipH controller. The controller begins a 60 minute countdown once the controller's power leads are energized. The power applied to the controller occurs at the same time that the filter pump circuit is energized within the automation.

So, this is the sequence of events...

1. Filter pump circuit is activated by the automation.

2. Power is now applied to the ipH controller. A 60 minute timer countdown begins.

3. After 60 minutes, the controller signals the peristaltic pump (P. pump) to begin pumping the 50% diluted muriatic acid solution.

4. The P. pump will continue to pump for as many seconds as determined by the ipH controller. (remember this pump time is actually determined and set by the user as a percentage number), up to a maximum of 60 seconds (100%).

5. The ipH then signals the P.pump to stop pumping the solution and begins the countdown once again.

This sequence of events occurs every hour, so long as the filter pump circuit is energized. Once the filter pump schedule is completed within the automation, the filter pump circuit is deactivated and power is then removed from the load-side of the relay that delivers power to the IC transformer. Now the ipH controller has no power, hence the cycle is complete.

So, the long answer given above to your question is: So long as the ipH controller has power, it will pump solution every hour. How much solution it pumps every hour is determined by the percentage value set by the user up to a maximum of 60 seconds (100%) per hour.

Some Stenners come with a built in timer (econT) but the user is still responsible for all run rate calculations. The econT comes with 24 timers that could be setup similarly (like the IntellipH) to run every hour/every day for a certain amount of time...however the minimum run time is one minute so that would require use of one of the lower flow stenners (ex ET210F dispenses .11oz/min) for use with MA dispersals. Unlike the IntellipH, there is no provision for dialing back those programmed dispersal times. The timers would have to be changed manually.

Essentially my timer is in the automation. It determines when the ipH controller is powered on or not.

I took a look at the Econ T Series... Right, the EconT is dummer that the IpH, because like you pointed out, a user cannot dial back the dispersal times (amount of seconds per hour of dispersal)..

Thanks Jon, maybe since your still around the corner, if you want to see if we can tackle this project together at some point, I'm all in. I still need to take a look at that buried tank solution you came up with.

r.