Hello,

Recently, I decided to take a look inside the balance tank to clean it and inspect the auto valve and everything else. I performed the following activities:

Below my findings:

The balance tank seems much better than before, however it seems obvious it will deteriorate more if I don't do something, and I think now is a good opportunity (its already empty and is still summer by here).

Below some proposals:

I appreciated any feedback, regarding these proposals and if make any sense. I don't have any experience repairing tanks, but I already use these products in others environments.

Thanks

Recently, I decided to take a look inside the balance tank to clean it and inspect the auto valve and everything else. I performed the following activities:

- Remove all water inside (using pool pump and later using a wet vacuum)

- Apply pressure water (with a pressure jet) to all walls, floor and roof

- Get all debris and water with a wet vacuum

Below my findings:

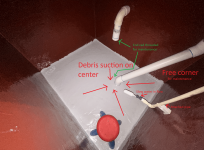

- All the debris was removed (wet vacuum after various iterations)

- The wall paint (waterproofing coating) is almost disappear (if any). NOTE: the pressure water didn't remove it.

- The concrete walls include a filler (it seems OVERCOAT Z-GRIP)

- The floor is very damaged

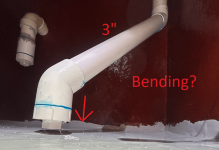

- The water supply pipe (PVC 1/2in) is not attached to the wall, and it bend when the water supply rise too much. It seems there was an anchor which got rusted. NOTE: I removed the floating valve during cleaning.

The balance tank seems much better than before, however it seems obvious it will deteriorate more if I don't do something, and I think now is a good opportunity (its already empty and is still summer by here).

Below some proposals:

- Replace the floating valve with a Kerick Valve MA052 which, has a small floating device which could cause less bending to the pipe when the water rise, and it seems good according with the reviews.

- I remove water from the pool to avoid water inside the overflow channels

- Closed (with PVC glue and end cap) the overflow drain to avoid further water coming inside.

- Add a new ancle to attached the water supply pipe to the wall and avoid bending. Perhaps inox or galvanize and cover later with coating.

- Repair the concrete (walls and floor):

- Apply an acrylic concentrate primer sealer (Lanco® Acry-Seal)

- Fill the surface: (options)

- Add filler OVERCOAT Z-GRIP (this one, I could buy locally) as they did previously.

- Prepare a mix of cement (not quite sure about this yet) and level the surface to have a slope to the tank drain (which goes to the pump) in order to improve debris accumulation

- Apply waterproofing coating Polyurethane Based (KB-Pur 214 - KÖSTER)

- Remove the cap from the overflow drain

I appreciated any feedback, regarding these proposals and if make any sense. I don't have any experience repairing tanks, but I already use these products in others environments.

Thanks