| Line 48: | Line 48: | ||

If the Fenwal detects current when the gas valve is closed, the Fenwal determines that there is an error and refuses to operate. | If the Fenwal detects current when the gas valve is closed, the Fenwal determines that there is an error and refuses to operate. | ||

| − | |||

==Fenwal Replacement== | ==Fenwal Replacement== | ||

| Line 66: | Line 65: | ||

[[File:Heater Dirty Grounds.jpg|250px|thumb]] | [[File:Heater Dirty Grounds.jpg|250px|thumb]] | ||

One member found the ground wires connected to the bottom of the box were absolutely covered in mouse urine. He disconnected them, cleaned them with some sandpaper and rubbing alcohol to make sure he had a solid connection to the box, and it fixed his heater problem.<ref>https://www.troublefreepool.com/threads/solved-mastertemp-400-service-heater-light.196111/post-1729548</ref> | One member found the ground wires connected to the bottom of the box were absolutely covered in mouse urine. He disconnected them, cleaned them with some sandpaper and rubbing alcohol to make sure he had a solid connection to the box, and it fixed his heater problem.<ref>https://www.troublefreepool.com/threads/solved-mastertemp-400-service-heater-light.196111/post-1729548</ref> | ||

| + | |||

| + | ==Alternate Ground Circuit== | ||

| + | Fenwal ground problems are common enough that Pentair has a ground wire kit for the MasterTemp and Max-E_Therm heaters (KIT P/N 475214Z)<ref>https://www.pentair.com/content/dam/extranet/product-related/product-manuals/pool-and-spa-equipment/mastertemp/MasterTemp_and_Max-E-Therm_Heater_Groundwire_Kit_Installation_Instructions_English.pdf</ref>, and Fenwal has a technical article on "Improve Grounding in Gas Ignition Controls"<ref>https://www.troublefreepool.com/threads/simple-solution-to-fix-a-pool-heater-ground-problem.196573/</ref>. | ||

| + | |||

| + | Pool heaters often have a lot of ground wires that run from every different part of the metal firebox and sort of daisy-chain back to the control system ground. Problem is that severe service combined with a few small leaks can leave the heater a corrosion mess in short order. | ||

| + | |||

| + | The ground system is a very critical component for heater control since it works by producing a tiny signal to ground and then the control module detects it to be sure there's a flame. This technology is incredibly reliable so long as the ground system has no interference from corroded wires. If it doesn't detect this tiny signal (about 2 millionth's of an amp) due to corrosion the system will keep the gas valve closed. | ||

| + | |||

| + | To positively fix this you just run a wire from the burner base or from the burner flame holder on many of the new high efficiency heaters to the ground connection on the control module. | ||

Revision as of 16:42, 17 February 2020

Heater Flame Sensing

Do you have a gas heater where the heater briefly ignites and you get s puff of heat and then shuts down? If so you have have a flame sensing problem. This article will describe what may be happening and ways to fix it.

The Fenwal box

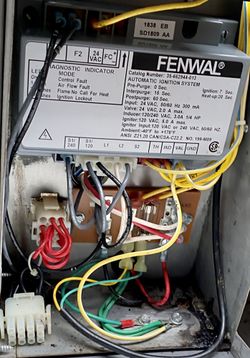

Many gas heaters, including the Pentair MasterTemp and Jandy LXI, use an electronic control box manufactured by Fenwal to safely control the gas valve and flame.

The flame sense circuit is extremely reliable and sensitive.[1] Testing for the flame sense signal is easy if you have the right equipment but if not it's easier just to assume you have a good signal with a new module. If this assumption is correct your problem is one of the following (so long as you hear the flame ignite and briefly feel heat from the exhaust):

- Corrosion in the grounding circuit

- Broken or corroded current sensing wire

- Interference in the ground signal

You can fix these as follows:

- Take the blower flange bolt loose and strip a wire with a longish strip ( 1inch or so) then slide it into the gap between the flange and the flame tube, Connect this to the yellow ground wires that are ganged inside the control panel (usually next to the Fenwel). Then restart the unit and see if this works. This will ensure you have a good ground connection to the Fenwel which is required to measure the tiny signal.

- If you have had potential issues like this from a rat problem in the past then double-check the wire by replacing it.

- If the power supply wire insulation to the unit is compromised you can have leakage to the ground circuit that is very small so the unit will actually work but the ground has sufficient interference that it prevents the flame sense circuit inside the Fenwel from working. This can cause the Fenwel test pin readings to indicate a bad module but it isn't bad it's your power supply quality. To test this simply rig up a temporary parallel supply wire. I used a piece of romex wire I had laying around in the garage. Run it to a different breaker if possible. This is a test wire only, don't leave it in place due to the obvious hazard. If your unit runs this way then just re-pull new supply wires.

Fenwal Disgnostics

Fenwal LED Light

The LED light on the Fenwal box can indicate the following problems:

- Two flashes indicates flame no call for heat, then the Fenwal is detecting a flame current when it shouldn't be

- Three flashes indicates no flame current being sensed and ignition locked out

Testing the Flame Sense Circuit

The Fenwal should have two test points for flame current FC+ and FC-. Flame current is the current that passes through the flame from sensor to ground.

The best way to measure the flame sense current is with a true RMS meter. Measure the current with a good true rms meter that can measure dc current in the microamp range.

To measure flame current, connect a True RMS or analog DC micro-ammeter to the FC+ and FC- terminals. Readings should be 1.0 µA DC or higher. If the meter reads negative or below "0" on scale, meter leads are reversed. Reconnect leads with proper polarity.

If you don't have a RMS meter you can just test for voltage between FC+ and FC- terminals to confirm if you have flame sense. Each micro-amp of flame current produces 1.0 VDC. For example, 2.6 VDC equates to 2.6 µA. Voltage is an indirect indication but easier to do with typical DIY equipment. But it's still very difficult to measure unless you make up some pin wires to clip your voltmeter to. Or you can order some insulated micro clips for the test.

The reading should be 3-8 volts and this corresponds to the millionth's of an amp signal your flame sense signal should reading. If you try to check this be very careful since you can easily short the 24 vac circuit which can blow the transformer before the 2 amp fuse blows.

When not operating, the flame current should read 0 volts dc and 0 microamps dc. DC amps and voltage should be zero when there is no flame.[2]

When there is a flame, there are ions in the flame that can carry current from the flame sensor to the burner and then through the ground back to the Fenwal.

The current mostly goes in one direction, so it's "rectified" from ac to dc.

This is called "flame rectification" and it's how the Fenwal verifies that the burners actually light when the gas valve opens.

If the Fenwal detects current when the gas valve is closed, the Fenwal determines that there is an error and refuses to operate.

Fenwal Replacement

You may find that the easiest way to eliminate the Fenwal box from the problem is by replacing it. It is best to get a replacement box from an authorized Fenwal reseller. A member bought a replacement Fenwal box from a cheap eBay seller which did not work properly.

Ground Problems

If you are confident you have an operating Fenwal box and a new igniter then it is likely your problem is a bad burner ground. A good burner ground that matches the control ground is critical for reliable flame sensing.[3]

If you're getting flame no call for heat, it might be a bad ground or stray current or bad controller.

If there's corrosion in the connection between the burner and chassis or Fenwal and the heater chassis, the flame current won't make the path from the Fenwal to the flame sensor, through the flame, to the burner and back to the Fenwal.

A microcurrent has to travel from the Fenwal, though the flame sensor, through the flame, to the burner and then through the frame grounding back to the Fenwal.[4] You need to make sure that the Fenwal is securely grounded to the frame and that there is a good ground path between the Fenwal and the burner.

The burner and the Fenwal need to share a common ground to reliably monitor the flame current. Since the current is so small, having a different ground reference can cause errors. You might also have some voltage leaking to ground causing random currents. Check for voltage between the main equipment ground and the heater chassis and between the bond wire and the heater chassis.

One member found the ground wires connected to the bottom of the box were absolutely covered in mouse urine. He disconnected them, cleaned them with some sandpaper and rubbing alcohol to make sure he had a solid connection to the box, and it fixed his heater problem.[5]

Alternate Ground Circuit

Fenwal ground problems are common enough that Pentair has a ground wire kit for the MasterTemp and Max-E_Therm heaters (KIT P/N 475214Z)[6], and Fenwal has a technical article on "Improve Grounding in Gas Ignition Controls"[7].

Pool heaters often have a lot of ground wires that run from every different part of the metal firebox and sort of daisy-chain back to the control system ground. Problem is that severe service combined with a few small leaks can leave the heater a corrosion mess in short order.

The ground system is a very critical component for heater control since it works by producing a tiny signal to ground and then the control module detects it to be sure there's a flame. This technology is incredibly reliable so long as the ground system has no interference from corroded wires. If it doesn't detect this tiny signal (about 2 millionth's of an amp) due to corrosion the system will keep the gas valve closed.

To positively fix this you just run a wire from the burner base or from the burner flame holder on many of the new high efficiency heaters to the ground connection on the control module.

- ↑ https://www.troublefreepool.com/threads/mastertemp-400-igniting-momentarily-no-diagnostic-codes.197971/post-1747064

- ↑ https://www.troublefreepool.com/threads/solved-mastertemp-400-service-heater-light.196111/post-1729308

- ↑ https://www.troublefreepool.com/threads/solved-mastertemp-400-service-heater-light.196111/post-1729135

- ↑ https://www.troublefreepool.com/threads/pentair-mastertemp-ignition-lockout.194330/post-1713998

- ↑ https://www.troublefreepool.com/threads/solved-mastertemp-400-service-heater-light.196111/post-1729548

- ↑ https://www.pentair.com/content/dam/extranet/product-related/product-manuals/pool-and-spa-equipment/mastertemp/MasterTemp_and_Max-E-Therm_Heater_Groundwire_Kit_Installation_Instructions_English.pdf

- ↑ https://www.troublefreepool.com/threads/simple-solution-to-fix-a-pool-heater-ground-problem.196573/