| (44 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

=Jandy AquaPure SWG= | =Jandy AquaPure SWG= | ||

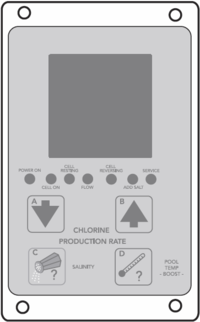

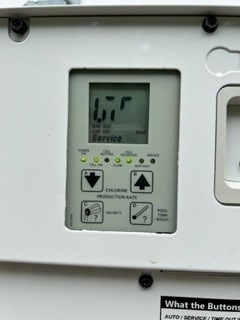

[[File:Jandy AquaPure SWG User Interface.png|200px|thumb]] | [[File:Jandy AquaPure SWG User Interface.png|200px|thumb]] | ||

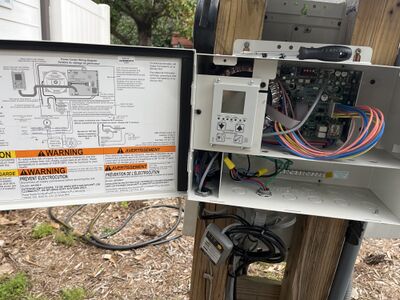

| − | The Jandy AquaPure system consists of | + | [[File:Jandy Aquapure SWG.jpg|thumb]] |

| + | The Jandy AquaPure system consists of an AquaPure Power Center or PureLink Power Center and either a PURE700 cell or a PURE1400 cell. The PureLink Power Centers combine all the features of the AquaLink Power Centers and AquaPure water purification electronics in one box. | ||

| + | |||

| + | [[File:Jandy Purelink Aquapure open.jpg|400px|thumb]] | ||

[[File:Jandy Aquapure Power Interface Board.jpg|400px|thumb]] | [[File:Jandy Aquapure Power Interface Board.jpg|400px|thumb]] | ||

| − | The AquaPure salt-water chlorine sanitizing | + | The AquaPure salt-water chlorine sanitizing system uses salt water to deliver water sanitation by generating chlorine. |

The AquaPure cells can be controlled by the AquaPure user interface inside the control/power center or by the Aqualink automation systems. | The AquaPure cells can be controlled by the AquaPure user interface inside the control/power center or by the Aqualink automation systems. | ||

==AquaPure Cell Capacity== | ==AquaPure Cell Capacity== | ||

| − | The AquaPure system offers two cells that can generate different maximum amounts of chlorine in a 24 hour period. You use the % generation control to adjust the actual amount of chlorine generated to meet your | + | The AquaPure system offers two cells that can generate different maximum amounts of chlorine in a 24 hour period. You use the % generation control to adjust the actual amount of chlorine generated to meet your pool's chlorine need. |

*PURE700 - 0.625 lb./24 Hr. (283 gm/24 Hr.) | *PURE700 - 0.625 lb./24 Hr. (283 gm/24 Hr.) | ||

| Line 33: | Line 36: | ||

The Jandy tri-sensor measures water flow, salinity, and water temperature. | The Jandy tri-sensor measures water flow, salinity, and water temperature. | ||

| − | The AquaPure does not have a flow switch, it has a flow sensor, which is a heated probe and and unheated probe and it works on the same principle as "wind chill".<ref>https://www.troublefreepool.com/threads/need-intelliflo-and-jandy-aquapure-1400-folks.254612/post- | + | The AquaPure does not have a flow switch, it has a flow sensor, which is a heated probe and and unheated probe and it works on the same principle as "wind chill".<ref>https://www.troublefreepool.com/threads/need-intelliflo-and-jandy-aquapure-1400-folks.254612/post-2226671y</ref> |

| + | |||

| + | The sensor works by heating a little metal button exposed inside the cell. The more water flow, the more heat is drawn away from the button, and the more current to the heater. The electronics in the box sense this current.<ref>https://www.troublefreepool.com/threads/testing-aqua-pure-salt-cell-is-it-cooked.309133/post-2697978</ref> | ||

| + | |||

| + | Causes of NO FLOW can be: | ||

| + | *Actual low flow. VSP set too low? Make sure skimmers, pump basket, are filter is clean and nothing else clogged. | ||

| + | *Crust (like calcium) over the button. Water can't carry the heat away. Check by removing the sensor and looking for it. Clean gently as needed. | ||

| + | *Failing heater element. Can't draw expected current. Replace sensor. | ||

| + | *Sensor wiring problem. Check connections inside the box. | ||

| + | *Bad electronics in the box. Least likely, but if the flow and sensor are good, this is all that's left. | ||

If you have a No-Flow error try resetting the circuit breaker and re-calibrating the tri-sensor before you consider replacing it. | If you have a No-Flow error try resetting the circuit breaker and re-calibrating the tri-sensor before you consider replacing it. | ||

| − | You can find instructions | + | You can find instructions for replacing and calibrating the tri-sensor in the [https://www.poolsupplyunlimited.com/Products/Manuals/53059_20139413550.pdf AquaPure and PureLink Tri-Sensor Adapter Installation Kit Manual]. |

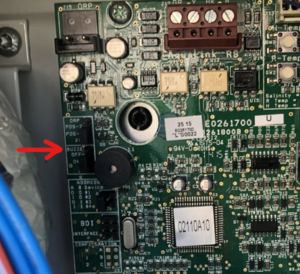

What is the Software number on the CPU? | What is the Software number on the CPU? | ||

| − | If it’s 02110A10 or 01220A15, you use program A, otherwise you use program B on the in-line module on the | + | If it’s 02110A10 or 01220A15, you use program A, otherwise you use program B on the in-line module on the tri-sensor cord. Don’t use the little adaptor card between the cord plug and the circuit board. |

| − | Here is a test you can do to diagnose the | + | Here is a test you can do to diagnose the tri-sensor. |

Disconnect the flow salinity temp sensor from the board. | Disconnect the flow salinity temp sensor from the board. | ||

| − | Press and hold the test buttons marked salinity and R-temp. While still pressing the test buttons press the ‘Salinity’ key (‘C’) on the front cover | + | Press and hold the test buttons marked salinity and R-temp. While still pressing the test buttons, press the ‘Salinity’ key (‘C’) on the unit's front cover. The LCD should read 2.8 gpl*. |

| − | While still holding the two front board test buttons press the ‘Pool Temperature’ key (‘D’). It should read 75° F or 24° C. | + | While still holding the two front board test buttons, press the ‘Pool Temperature’ key (‘D’). It should read 75° F or 24° C. |

| − | Next, press and hold the board ‘H-Temp’ test button, and at the same time press the ‘Salinity’ key (‘C’) together with the ‘Chlorine Production Rate’ arrow down key (‘A’) on the front cover | + | Next, press and hold the board ‘H-Temp’ test button, and at the same time, press the ‘Salinity’ key (‘C’) together with the ‘Chlorine Production Rate’ arrow down key (‘A’) on the unit's front cover. The LCD should read 91° F or 33° C. |

| − | If the readings are correct then the board is O.K. and the problem is with the flow sensor. On the other hand if the readings are different | + | If the readings are correct, then the board is O.K., and the problem is with the flow sensor. On the other hand, if the readings are different, it indicates a problem with the board. |

==Salinity== | ==Salinity== | ||

| − | With the AquaPure 1400, the reading is in grams per liter, which is the same as 1,000 ppm. 3 | + | With the AquaPure 1400, the reading is in grams per liter, which is the same as 1,000 ppm. 3 GPL is 3,000 ppm. |

| − | If the salinity | + | If the salinity exceeds 4.0 GPL, the unit will cut off and give error code 145 (High Salinity). |

The Salinity button C on the sanitizer user interface keypad can be used to determine salinity. | The Salinity button C on the sanitizer user interface keypad can be used to determine salinity. | ||

| − | *3.0 to 3.5 | + | *3.0 to 3.5 GPL of salt is recommended for optimum water conditions. |

| − | *Low salt concentration below 2.0 | + | *Low salt concentration below 2.0 GPL will cause premature cell failure. |

| − | *High salt concentration above 4.0 | + | *High salt concentration above 4.0 GPL may damage the power center. |

| − | + | Ensure the salt is mixed well by brushing thoroughly at least 5 times. | |

| − | If the actual salinity is above 4.0 | + | If the actual salinity is above 4.0 GPL (4,000 ppm), the pool must be diluted to get below 4.0 GPL. |

The manual says that the unit can be damaged, which could void the warranty. | The manual says that the unit can be damaged, which could void the warranty. | ||

| + | ===Salinity Calibration=== | ||

| + | |||

| + | You can check the calibration by following the procedure below. | ||

| + | |||

| + | *If the unit reads 2.8 GPL for salinity, then the unit has not been recalibrated. | ||

| + | *If the unit does not read 2.8 GPL for salinity, then the unit has been recalibrated. | ||

| − | + | You can recalibrate the unit if you know the actual salinity and want the box to match your readings. | |

| − | + | [[File:Jandy Aquapure Salinity RTemp Buttons.png|thumb]] | |

| + | |||

| + | Test procedure: | ||

| + | *Disconnect the flow salinity temp sensor from the front board. Press and hold the test buttons marked salinity and R-temp. | ||

| + | *While still pressing the test buttons, press the ‘Salinity’ key (‘C’) on the unit's front cover. The LCD should read 2.8 GPL*. | ||

| + | *Press the' Pool Temperature' key while holding the two front board test buttons (‘D’). It should read 75° F or 24° C. | ||

| + | *Next, press and hold the board ‘H-Temp’ test button, and at the same time press the ‘Salinity’ key (‘C’) together with the ‘Chlorine Production Rate’ arrow down key (‘A’) on the front cover of the unit. The LCD should read 91° F or 33° C. | ||

| + | |||

| + | ===Salinity Recalibration procedure=== | ||

| − | + | *Press the “Salinity” button and hold it until it beeps 3 times. The system will beep when you push it, then at 5 seconds, and again at 10 seconds. | |

| + | *Release the button after the 3rd beep. Press and release the “Temperature “ button within 5 seconds to enter the salinity calibration screen. | ||

| + | *The system will display the salinity reading. Press the up arrow to increase the reading and the down arrow to decrease it. | ||

| + | *When the proper reading is reached, press the “Temperature” button within 5 seconds to store it in memory. | ||

| − | + | See pages 13-14 in [https://images.inyopools.com/cloud/documents/jandy-aqua-pure-error-codes.pdf Jandy AquaPure Troubleshooting]. | |

==Audible Alarm== | ==Audible Alarm== | ||

| − | The audible alarm is described on page | + | The audible alarm is described on page 33 of the Jandy® Pro Series AquaPure®/PureLink™ Power Center and Cell Kit | Installation and Operation Manual.<ref>https://www.jandy.com/-/media/zodiac/global/downloads/h/h0325600.pdf</ref> |

| − | Adjusting the audible alarm volume is also described on page | + | Adjusting the audible alarm volume is also described on page 33 of the Installation Manual. |

| − | The audible alarm can be permanently | + | The audible alarm can be permanently turned off by removing the jumper from J2 on the control/power center Power Interface Board (PIB). |

| + | |||

| + | [[File:Jandy Aquapure J2 Audible Alarm.png|thumb]] | ||

==Cold Water Operation== | ==Cold Water Operation== | ||

| + | |||

| + | The display will show the LO code. LO indicates the temperature of Pool is < 54ºF (12.2°C). Chlorine production is stopped. | ||

| + | |||

| + | [[File:Jandy AquaPure LO Code.jpg|thumb]] | ||

From Page 39 of the Installation Manual: | From Page 39 of the Installation Manual: | ||

| − | + | Chlorine production is not permitted below 51°F (11°C); operating the chlorinator in cold water might result in over-chlorinated pool water. If more chlorine is needed, activating the “Boost” mode will override this cold water feature allowing chlorine production for 24 hours of operation. | |

| − | This applies to the Jandy AquaPure and the Nature2 FusionSoft as they are sister products. An optional "Spool" Piece (sold separately) used to be available to replace the cell during winterizing or cell maintenance. This piece has been discontinued and is no longer available. In addition, the AquaPure threads are proprietary and Jandy does not offer replacement proprietary unions (the "male" piece). | + | This applies to the Jandy AquaPure and the Nature2 FusionSoft as they are sister products. An optional "Spool" Piece (sold separately) used to be available to replace the cell during winterizing or cell maintenance. This piece has been discontinued and is no longer available. In addition, the AquaPure threads are proprietary, and Jandy does not offer replacement proprietary unions (the "male" piece). |

| − | If removing the cell is desired so that water may circulate without the cell, specialized plumbing would need to be added during installation of the cell. One method is an additional PVC union after each end of the cell. This method would require the purchase of 4 unions. 2 for when the cell is installed and 1/2 of the other 2 unions (the "male" 1/2) for creation of the bypass pipe. | + | If removing the cell is desired so that water may circulate without the cell, specialized plumbing would need to be added during installation of the cell. One method is an additional PVC union after each end of the cell. This method would require the purchase of 4 unions. 2 for when the cell is installed and 1/2 of the other 2 unions (the "male" 1/2) for the creation of the bypass pipe. |

When a FREEZE CONTROLLER is used on pump equipment and the chlorinator is run through the winter, turn the CHLORINE PRODUCTION down to 10 - 20%. | When a FREEZE CONTROLLER is used on pump equipment and the chlorinator is run through the winter, turn the CHLORINE PRODUCTION down to 10 - 20%. | ||

| + | |||

| + | ==Jandy SP3P Dummy Cell== | ||

| + | |||

| + | Jandy has the [https://www.swimmingpoolsupplyusa.com/Jandy-SP3P-Cell-Cleaning-Kit-p/sp3p.htm Jandy SP3P Dummy Cell Cleaning Kit] that includes everything you need to remove, clean, store, and/or bypass your Jandy AquaPure 3-Port Salt Cell. | ||

| + | |||

| + | You can remove your cell for winter and install the dummy cell. | ||

==AquaPure Cycle Time== | ==AquaPure Cycle Time== | ||

| − | The AquaPure has a 3 hour cycle time. The percentage setting will control how much the cell runs during the cycle.<ref> https://www.troublefreepool.com/threads/ | + | The AquaPure has a 3 hour polarity cycle time (3 hours one polarity, 3 hours reverse polarity). The production cycle time used for chlorine production (observationally) is 30 minutes. The percentage setting will control how much the cell runs during the production cycle.<ref> https://www.troublefreepool.com/threads/aquapure-cycle-time-wiki-correction.264622/#post-2321916 </ref> |

| − | For example, at 50%, the | + | For example, at 50%, the cell will run for 15 minutes and off for 15 minutes. Polarity will change every 3 hours. |

Boost – 24 Hour 100% Chlorine Production Cycle. | Boost – 24 Hour 100% Chlorine Production Cycle. | ||

| Line 118: | Line 159: | ||

Here's another item of interest from p 877: | Here's another item of interest from p 877: | ||

| − | IMPORTANT NOTICE NO WARRANTY if purchased online. This is not a DIY product. Installation by a qualified pool professional required. Register product at Jandy.com/registration. | + | ''IMPORTANT NOTICE NO WARRANTY if purchased online. This is not a DIY product. Installation by a qualified pool professional required. Register product at Jandy.com/registration. |

| + | '' | ||

| + | ==Jandy Aquapure Parts Replacement== | ||

| + | Jandy has changed AquaPure parts over the models' life. If you have an older AquaPure system, you may require a different part to fix your system. | ||

| + | ===Aquapure Cell Replacement=== | ||

| + | |||

| + | You should replace the cell, tri-sensor, and power cord when the cell needs replacement. They are sold as a kit.<ref>https://www.troublefreepool.com/threads/plc1400-and-r0452400-compatible.260746/#post-2280305</ref> | ||

| + | |||

| + | You will also find the cell sold alone at a lower price than the kit, and it is tempting to buy only the cell. The PLC1400 cell is Jandy P/N R0452400. | ||

| + | |||

| + | The Flow & Salinity Sensor is Jandy P/N R0452500. | ||

| + | |||

| + | The PureLink DC Cord is Jandy P/N R0402800. | ||

| + | |||

| + | ===Replace the Power Cord When you Replace the Cell=== | ||

| + | |||

| + | When replacing the cell, it's important to replace the power cord so that the connections are clean and the resistance is minimized.<ref>https://www.troublefreepool.com/threads/six-month-old-jandy-plc1400-smoking-melting-rubber-wire-connector.198600/post-1752937</ref> | ||

| + | |||

| + | The prongs are sealed by O-rings and a compression plate held down by two screws. The problem is that the O-rings can leak, creating a corrosive mix of water, salt, hydrogen, and chlorine. This corrosion increases the resistance of the connection and generates a lot of heat due to the high current of 6 to 8 amps. | ||

| + | |||

| + | The center prong is the most common point of failure. You can usually see evidence of a leak when you know to look for it. | ||

| + | |||

| + | [[File:Jandy cell prongs LI.jpg|thumb]] | ||

| + | |||

| + | ===Replacing Cracked Aquapure Coupler Union=== | ||

| + | |||

| + | Jandy uses a proprietary thread on their unions. | ||

| + | |||

| + | [https://www.mikeysquickcoupler.com/product-page/jandy-9000 Mikeys Quick Coupler] sells a Jandy 9000 split union to replace a broken one without cutting the PVC pipe. | ||

| + | |||

| + | Otherwise, you need the Zodiac R0452100 Universal Union Replacement Kit. | ||

| + | |||

| + | You can get this kit, cut out your unions, and glue in a pipe, and then replace the unions... | ||

| + | |||

| + | [https://saltpoolstore.com/products/copy-of-jandy-aquapure-3-port-cell-union-kit Jandy Aquapure 3-port Cell Union Kit] | ||

| + | |||

| + | ===Replacing Power Interface Board Assembly (PIB)=== | ||

| − | ==Replacing Old Square Jandy PLC700/1400 Cell== | + | Jandy R0984100 Power Interface PCB Large Backboard with Screws for AquaPure and PureLink is used on units manufactured after 12/2007. It replaces the R0467600 PIB used on older units. |

| + | |||

| + | ===Replacing Old Square Jandy PLC700/1400 Cell=== | ||

Jandy switched to a 3-port cell design to aid in cleaning and plumbing flexibility and no longer makes 2-port cells. However, the Jandy PLC700 cell kit (for pools up to 12,000 gallons) and the PLC1400 (with a 40,000 gallon capacity) kit contain new cells as well as all the necessary accessories to switch a 2-port setup to the new design.<ref>https://www.troublefreepool.com/threads/jandy-old-square-salt-cell-replacement.201262/</ref> | Jandy switched to a 3-port cell design to aid in cleaning and plumbing flexibility and no longer makes 2-port cells. However, the Jandy PLC700 cell kit (for pools up to 12,000 gallons) and the PLC1400 (with a 40,000 gallon capacity) kit contain new cells as well as all the necessary accessories to switch a 2-port setup to the new design.<ref>https://www.troublefreepool.com/threads/jandy-old-square-salt-cell-replacement.201262/</ref> | ||

| Line 126: | Line 205: | ||

Adjustments to the wiring are: | Adjustments to the wiring are: | ||

| − | *Red goes to green and blue goes to black/white. | + | *Red goes to green, and blue goes to black/white. |

| − | *The sensor connects to the same spot. | + | *The sensor connects to the same spot. Remove the adapter card if there's a little adapter card between the old sensor cord and the circuit board. |

*Look at the label on the CPU for the firmware revision. | *Look at the label on the CPU for the firmware revision. | ||

| − | *If the power interface board firmware is 02110A10 or 01220A15, you use program A for the | + | *If the power interface board firmware is 02110A10 or 01220A15, you use program A for the tri-sensor. All other firmware uses program B on the tri-sensor inline module. |

| + | ===Replacing Power Center Transformer=== | ||

| + | |||

| + | Older power centers use a rectangular transformer P/N T1005 that is no longer available. Currently, Jandy has part R0481400, which is the round transformer. | ||

| + | |||

| + | A member found that the new part fit perfectly with the same mounting holes. Even the high-voltage side wires were color-coded identically. The only difference is the new part has a ground wire that was attached to the common ground.<ref>https://www.troublefreepool.com/threads/jandy-power-center-transformer-replacement-aquapure.194422/</ref> | ||

| + | <gallery> | ||

| + | File:Jandy T1005.png|thumb|Jandy T1005 | ||

| + | File:Jandy R0481400.png|thumb|Jandy R0481400 | ||

| + | File:Jandy T1005 Transformer.jpg|thumb|Jandy T1005 | ||

| + | File:Jandy T1005 Burnt Plug.jpg|thumb|Jandy T1005 Burnt Plug | ||

| + | </gallery> | ||

==Troubleshooting== | ==Troubleshooting== | ||

| Line 136: | Line 226: | ||

Also [https://images.inyopools.com/cloud/documents/jandy-aqua-pure-error-codes.pdf Jandy AquaPure Troubleshooting]. | Also [https://images.inyopools.com/cloud/documents/jandy-aqua-pure-error-codes.pdf Jandy AquaPure Troubleshooting]. | ||

| + | |||

| + | The voltage tests are a little tricky to do. There are three AC tests and four DC tests. If you don't get the right test points or the meter is not on the correct voltage type, your tests won't be correct.<ref>https://www.troublefreepool.com/threads/error-code-174.99273/post-885060</ref> | ||

===Pin Corrosion=== | ===Pin Corrosion=== | ||

| − | A common reason | + | A common reason the cell fails and gets error codes 120, 121, or 123 is one or more pins corroding and separating from its plate. Most common is the center pin.<ref>https://www.troublefreepool.com/threads/jandy-aquapure-1400-error-120.236117/</ref> |

You can remove the two screws holding down the plate over the prongs and check the base of the prongs. | You can remove the two screws holding down the plate over the prongs and check the base of the prongs. | ||

| Line 149: | Line 241: | ||

File:Jandy PLC1400 Corroded plate.png|Corroded Plate | File:Jandy PLC1400 Corroded plate.png|Corroded Plate | ||

File:Jandy PLC1400 Corroded Pins.png|Pins Missing | File:Jandy PLC1400 Corroded Pins.png|Pins Missing | ||

| + | File:Jandy cell prongs LI.jpg|Screws to Remove | ||

File:Jandy PLC1400 Cell Prongs.jpg|Screws Removed | File:Jandy PLC1400 Cell Prongs.jpg|Screws Removed | ||

File:Jandy P(LC1400 Corroded Center Pin.jpg|Center Pin Gone | File:Jandy P(LC1400 Corroded Center Pin.jpg|Center Pin Gone | ||

File:Jandy_PLC1400_Corroded_Center_Pin_Side_View.jpg | File:Jandy_PLC1400_Corroded_Center_Pin_Side_View.jpg | ||

</gallery> | </gallery> | ||

| + | |||

| + | ===Jandy Aquapure Diagnostic Codes=== | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |+ AquaPure LCD Codes | ||

| + | |- | ||

| + | ! CODE !! MEANING | ||

| + | |- | ||

| + | | LO || Water temperature is less than 51 deg. F and chlorine production is stopped | ||

| + | |- | ||

| + | | BO || Boost cycle has been activated by pressing the ‘Pool Temperature’ key for 10 seconds; it can be canceled by holding the same key for 10 seconds. | ||

| + | |- | ||

| + | | EC || Aquapure is controlled by an external controller or ORP device. | ||

| + | |- | ||

| + | | JA || Aquapure is controlled by a Jandy AquaLink RS or PDA, and the system is in AUTO MODE. | ||

| + | |- | ||

| + | | JO || Aquapure is controlled by a Jandy AquaLink RS or PDA, and the system is in SERVICE or TIME MODE. | ||

| + | |- | ||

| + | | JB || Aquapure is controlled by a Jandy AquaLink RS or PDA, and the system is in BOOST MODE | ||

| + | |} | ||

| + | |||

| + | The AquaPure will also display code "dE" that is not documented. Internet posting says the dE code means "Diagnostic mode."<ref>https://www.poolspaforum.com/forum/index.php?/topic/50761-jandy-aquapure-system-threw-de-code-now-will-not-operate/</ref> Someone posted that Jandy said it means that it has loaded the default settings.<ref>https://www.troublefreepool.com/threads/aquapure-de-error-code.111159/post-982198</ref> You can try holding the up and down arrows simultaneously for about 3 to 5 seconds, and it should reset itself. Otherwise, it seems the back circuit board (R0467600) needed to be replaced. | ||

| + | [[File:Jandy Aquapure Backboard R0467600.jpg|thumb]] | ||

===Jandy Aquapure Error Codes=== | ===Jandy Aquapure Error Codes=== | ||

| + | {| class="wikitable" | ||

| + | |+ Jandy AquaPure Service Codes | ||

| + | |- | ||

| + | ! Code # !! Possible Cause !! Solution | ||

| + | |- | ||

| + | |120|| Low current in forward direction to cell ||Clean cell if necessary and check DC cord | ||

| + | |- | ||

| + | |121|| Low current in reverse direction to cell||Clean cell if necessary and check DC cord | ||

| + | |- | ||

| + | |123|| Extremely low current to cell ||Clean cell if necessary and check DC cord | ||

| + | |- | ||

| + | |124|| Higher than normal current to cell ||Contact a pool professional | ||

| + | |- | ||

| + | |125|| Cell needs to be cleaned ||Clean cell if necessary | ||

| + | |- | ||

| + | |126|| Low current in the forward direction and VAC input voltage below 100-200 VAC ||Contact a pool professional | ||

| + | |- | ||

| + | |127|| Low current in reverse direction and VAC input voltage below 100-200 VAC ||Contact a pool professional | ||

| + | |- | ||

| + | |144|| Low Salinity (below 2.0 gpl) ||Add salt to pool to achieve 3.0 GPL | ||

| + | |- | ||

| + | |145|| High Salinity (above 4.0 gpl) ||Backwash filter if a DE filter is installed. Partially drain pool and dilute with fresh water until salinity returns to 3.0 to 3.5 GPL | ||

| + | |- | ||

| + | |170|| Possible front board service condition or unit not correctly wired to 120 VAC ||Contact a pool professional | ||

| + | |- | ||

| + | |171|| Possible backboard service condition ||Contact a pool professional | ||

| + | |- | ||

| + | |172|| Flow sensor service condition or flow sensor is unplugged ||Contact a pool professional | ||

| + | |- | ||

| + | |173|| Low VAC input voltage and on board power supply is not regulated or unit not correctly wired Unit wired to improper AC voltage. ||Contact a pool professional | ||

| + | |- | ||

| + | |174|| Pool temperature is too high for operation of AquaPure Flow/Salinity sensor indicated water temperature at sensor above 108 degrees F. ||Reduce water temperature | ||

| + | |- | ||

| + | |175|| Flow sensor air lock condition or very low salinity ||Verify proper flow/temperature/salinity sensor installation. Check salinity with Myron “L” meter calibrated for NaCl or test strips. Add salt as necessary | ||

| + | |} | ||

| + | |||

| + | |||

| + | {| class="wikitable" | ||

| + | |+ Jandy AquaPure Level 2 Service Codes | ||

| + | |- | ||

| + | ! Code # !! Possible Cause !! Solution | ||

| + | |- | ||

| + | |180|| Heated sensor element not heating. (Generates 172 code) ||Contact a pool professional | ||

| + | |- | ||

| + | |181|| Flow sensor temperature sensor failure. (Generates 172 code – flow sensor service) ||Contact a pool professional | ||

| + | |- | ||

| + | |182|| Salinity Sensor sees less than 0.2 gpl of salt, no salt in pool or sensor air locked. (Generates 175 code – flow sensor air lock) ||Contact a pool professional | ||

| + | |- | ||

| + | |183, 184, 185, 186|| Flow salinity sensor temperature probe error codes. (They will all generate 172 codes which indicate flow sensor service is required) ||Contact a pool professional | ||

| + | |- | ||

| + | |187|| Front board power supply either too low or too high. (Generates 173 – Low input voltage code if Level 2 code 188 is present) (Generates 170 code if 188 is not present) ||Contact a pool professional | ||

| + | |- | ||

| + | |188|| VAC input voltage is too low. (Generates 173 code if Level II code 187 is present) ||Contact a pool professional | ||

| + | |- | ||

| + | |189|| Relay not conducting in the forward direction. (Generates 171 code – Backboard service) ||Contact a pool professional | ||

| + | |- | ||

| + | |190|| Relay not conducting in the reverse direction. (Generates 171code – Backboard service) ||Contact a pool professional | ||

| + | |- | ||

| + | |191|| High cell current (at upper limit of A/D converter) and cell voltage below 19V. (Generates 170 code front board service) ||Contact a pool professional | ||

| + | |- | ||

| + | |192|| High cell current and cell voltage below 19V. (generates 171 code – Backboard service) ||Contact a pool professional | ||

| + | |- | ||

| + | |193|| Measured significant cell current when SCRs were turned off. (Generates 170 code – front board service) ||Contact a pool professional | ||

| + | |- | ||

| + | |194|| Cell Current is 85% lower than desired and cell voltage above 19V (Generates 125 code – Cell dirty or needs replacement) ||Contact a pool professional | ||

| + | |- | ||

| + | |195|| Salinity invalid due to out-of-range measurements caused by front board error (Generates 170 code – front board service) ||Contact a pool professional | ||

| + | |} | ||

====Error 120==== | ====Error 120==== | ||

| − | 120 is low current. That can be from low salt, low water temperature, a bad power cord, cell plates | + | 120 is low current. That can be from low salt, low water temperature, a bad power cord, corroded cell plates, or loose power pins. Make sure the temperature is above 60, the salt is 3400, and the power cord is good. Then, look in the cell at the plates with a good light from both ends to see if the plates are corroded. |

====Error 121==== | ====Error 121==== | ||

| − | A 121 error can occur for | + | A 121 error can occur for several different reasons: a dirty cell, a damaged cell, a bad cell cable, a low salt level, a cell wearing out due to age, or a damaged power supply. |

Test the salt level with a K-1766 Taylor Salt Test. | Test the salt level with a K-1766 Taylor Salt Test. | ||

| + | |||

| + | ====Error 123==== | ||

| + | |||

| + | That error is low or no current to the cell. The first thing to check is the cord. Look for heavy corrosion at both ends. You can sometimes fix it by cleaning off the corrosion.<ref>https://www.troublefreepool.com/threads/aquapure-1400-receiving-error-code-123.46288/post-387518</ref> | ||

| + | |||

| + | Also, look inside the cell at the cord end. The three pins go inside and connect to the plates. If one is rotted away, it's time for a new cell and cord. | ||

| + | |||

| + | Otherwise, the back circuit board may need replacement. | ||

===Cell Amperage=== | ===Cell Amperage=== | ||

| Line 173: | Line 365: | ||

[[File:Jandy Aquapure Tri-Sensor.jpg|150px|thumb]] | [[File:Jandy Aquapure Tri-Sensor.jpg|150px|thumb]] | ||

| − | When the tri-sensor fails the salinity will be incorrect or you will get a no-flow error. | + | When the tri-sensor fails, the salinity will be incorrect, or you will get a no-flow error. |

| − | Note that the center prong is on the cell where the power cord connects to the cell. This issue is with the | + | Note that the center prong is on the cell where the power cord connects to the cell. This issue is with the tri-sensor, a separate part installed in the cell. |

| − | It's usually cheaper to buy the Aquapure 1400 cell kit | + | It's usually cheaper to buy the Aquapure 1400 cell kit, which includes the cell, tri-sensor, and power cord, than to buy the parts separately. |

| − | If the cell is old, | + | If the cell is old, get the PLC1400 kit. |

===Aquapure Not Taking Aqualink Changes=== | ===Aquapure Not Taking Aqualink Changes=== | ||

| − | Aqualink prevents the Aquapure system from proper operation without a functioning water temperature signal from the Aqualink stand alone water temperature sensor, regardless of what the SWG flow sensor says. | + | Aqualink prevents the Aquapure system from proper operation without a functioning water temperature signal from the Aqualink stand-alone water temperature sensor, regardless of what the SWG flow sensor says. |

It appears that Aqualink stops talking to Aquapure when the Aqualink water temperature sensor is inoperative.<ref>https://www.troublefreepool.com/threads/will-a-new-water-temp-sensor-fix-this-aquapure-swg-scenario.243392/</ref> | It appears that Aqualink stops talking to Aquapure when the Aqualink water temperature sensor is inoperative.<ref>https://www.troublefreepool.com/threads/will-a-new-water-temp-sensor-fix-this-aquapure-swg-scenario.243392/</ref> | ||

| − | Changes to Aquapure settings made on Aqualink will not show on the Aquapure and the chlorine % will be 0. | + | Changes to Aquapure settings made on Aqualink will not show on the Aquapure, and the chlorine % will be 0. |

| − | If the Aquapure is disconnected from the Aqualink, | + | If the Aquapure is disconnected from the Aqualink, you should be able to set chlorine production from the front panel. |

===Jandy PDA not displaying AquaPure info=== | ===Jandy PDA not displaying AquaPure info=== | ||

| − | Many AquaPure display problems seem to | + | Many AquaPure display problems seem to be fixed by powering the Power Center and Aqualink panel if connected off at the circuit breakers, waiting a few minutes, and powering everything back on.<ref> https://www.troublefreepool.com/threads/jandy-pda-wasnt-displaying-aquapure-info.194647/post-1715658 </ref> |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | ===AquaPure Resets to 35% every time it is Powered On=== | |

| − | + | A member had the problem of his Aquapure resetting to 35% every time the timer powered it on.<ref>https://www.troublefreepool.com/threads/aquapure-keeps-resetting-to-chlorine-rate-35-from-pool-pump-timer.197670/post-1743853</ref> After discussions with a Jandy representative it was determined the problem was a bad board. | |

| − | |||

| − | + | ===Aquapure Display Garbled=== | |

| − | + | [[File:Jandy Aquapure Display Garbled.jpg|thumb]] | |

| − | + | Check the ribbon cable and reboot the system. | |

| − | |||

| − | |||

| − | |||

| − | === | + | ===Fahrenheit or Celsius Temperature Displayed=== |

| − | + | When the AquaPure first turns on, the number 60 should be displayed briefly. That is the power supply frequency that the unit detects. If it reads 60 Hz, it assumes the unit is in the US and displays Fahrenheit. If it detects 50 Hz, it will flash 50 on the screen, think it's in Europe, and display Celsius.<ref>https://www.troublefreepool.com/threads/error-code-174.99273/post-896321</ref> | |

| − | + | ==AquaPure History== | |

| − | |||

| − | |||

| − | + | Chloromatic developed the AquaPure system in the 1990's. Jandy acquired Chloromatic in the early 2000's. Chloromatic and early Jandy systems used cells with 2 ports. A design change Jandy made was changing the cell from 2 ports to 3 ports. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | A | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Latest revision as of 03:31, 10 April 2025

Jandy AquaPure SWG

The Jandy AquaPure system consists of an AquaPure Power Center or PureLink Power Center and either a PURE700 cell or a PURE1400 cell. The PureLink Power Centers combine all the features of the AquaLink Power Centers and AquaPure water purification electronics in one box.

The AquaPure salt-water chlorine sanitizing system uses salt water to deliver water sanitation by generating chlorine.

The AquaPure cells can be controlled by the AquaPure user interface inside the control/power center or by the Aqualink automation systems.

AquaPure Cell Capacity

The AquaPure system offers two cells that can generate different maximum amounts of chlorine in a 24 hour period. You use the % generation control to adjust the actual amount of chlorine generated to meet your pool's chlorine need.

- PURE700 - 0.625 lb./24 Hr. (283 gm/24 Hr.)

- PURE1400 - 1.25 lb./24 Hr. (567 gm/24 Hr.)

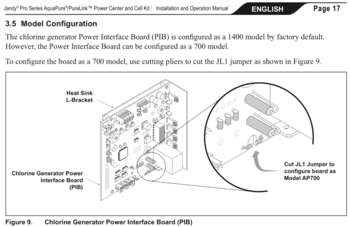

Model Configuration

Both cells use the same Power Center box. However there is a jumper on the Power Interface Board that is connected for the 1400 cell and cut for the 700 cell. The Power Center comes configured for the 1400 cell and the JL1 jumper must be cut if using the 700 cell.

If you are switching from the 700 cell to the 1400 cell the JL1 jumper needs to be reconnected.

The PLC700's have a 2 prong plug system and the PLC1400's have a 3 prong plug system.

Page 17 in the Jandy Power Center Installation Manual shows the location of the jumper.

Jandy Tri-Sensor

The Jandy tri-sensor measures water flow, salinity, and water temperature.

The AquaPure does not have a flow switch, it has a flow sensor, which is a heated probe and and unheated probe and it works on the same principle as "wind chill".[1]

The sensor works by heating a little metal button exposed inside the cell. The more water flow, the more heat is drawn away from the button, and the more current to the heater. The electronics in the box sense this current.[2]

Causes of NO FLOW can be:

- Actual low flow. VSP set too low? Make sure skimmers, pump basket, are filter is clean and nothing else clogged.

- Crust (like calcium) over the button. Water can't carry the heat away. Check by removing the sensor and looking for it. Clean gently as needed.

- Failing heater element. Can't draw expected current. Replace sensor.

- Sensor wiring problem. Check connections inside the box.

- Bad electronics in the box. Least likely, but if the flow and sensor are good, this is all that's left.

If you have a No-Flow error try resetting the circuit breaker and re-calibrating the tri-sensor before you consider replacing it.

You can find instructions for replacing and calibrating the tri-sensor in the AquaPure and PureLink Tri-Sensor Adapter Installation Kit Manual.

What is the Software number on the CPU?

If it’s 02110A10 or 01220A15, you use program A, otherwise you use program B on the in-line module on the tri-sensor cord. Don’t use the little adaptor card between the cord plug and the circuit board.

Here is a test you can do to diagnose the tri-sensor.

Disconnect the flow salinity temp sensor from the board.

Press and hold the test buttons marked salinity and R-temp. While still pressing the test buttons, press the ‘Salinity’ key (‘C’) on the unit's front cover. The LCD should read 2.8 gpl*.

While still holding the two front board test buttons, press the ‘Pool Temperature’ key (‘D’). It should read 75° F or 24° C.

Next, press and hold the board ‘H-Temp’ test button, and at the same time, press the ‘Salinity’ key (‘C’) together with the ‘Chlorine Production Rate’ arrow down key (‘A’) on the unit's front cover. The LCD should read 91° F or 33° C.

If the readings are correct, then the board is O.K., and the problem is with the flow sensor. On the other hand, if the readings are different, it indicates a problem with the board.

Salinity

With the AquaPure 1400, the reading is in grams per liter, which is the same as 1,000 ppm. 3 GPL is 3,000 ppm.

If the salinity exceeds 4.0 GPL, the unit will cut off and give error code 145 (High Salinity).

The Salinity button C on the sanitizer user interface keypad can be used to determine salinity.

- 3.0 to 3.5 GPL of salt is recommended for optimum water conditions.

- Low salt concentration below 2.0 GPL will cause premature cell failure.

- High salt concentration above 4.0 GPL may damage the power center.

Ensure the salt is mixed well by brushing thoroughly at least 5 times.

If the actual salinity is above 4.0 GPL (4,000 ppm), the pool must be diluted to get below 4.0 GPL.

The manual says that the unit can be damaged, which could void the warranty.

Salinity Calibration

You can check the calibration by following the procedure below.

- If the unit reads 2.8 GPL for salinity, then the unit has not been recalibrated.

- If the unit does not read 2.8 GPL for salinity, then the unit has been recalibrated.

You can recalibrate the unit if you know the actual salinity and want the box to match your readings.

Test procedure:

- Disconnect the flow salinity temp sensor from the front board. Press and hold the test buttons marked salinity and R-temp.

- While still pressing the test buttons, press the ‘Salinity’ key (‘C’) on the unit's front cover. The LCD should read 2.8 GPL*.

- Press the' Pool Temperature' key while holding the two front board test buttons (‘D’). It should read 75° F or 24° C.

- Next, press and hold the board ‘H-Temp’ test button, and at the same time press the ‘Salinity’ key (‘C’) together with the ‘Chlorine Production Rate’ arrow down key (‘A’) on the front cover of the unit. The LCD should read 91° F or 33° C.

Salinity Recalibration procedure

- Press the “Salinity” button and hold it until it beeps 3 times. The system will beep when you push it, then at 5 seconds, and again at 10 seconds.

- Release the button after the 3rd beep. Press and release the “Temperature “ button within 5 seconds to enter the salinity calibration screen.

- The system will display the salinity reading. Press the up arrow to increase the reading and the down arrow to decrease it.

- When the proper reading is reached, press the “Temperature” button within 5 seconds to store it in memory.

See pages 13-14 in Jandy AquaPure Troubleshooting.

Audible Alarm

The audible alarm is described on page 33 of the Jandy® Pro Series AquaPure®/PureLink™ Power Center and Cell Kit | Installation and Operation Manual.[3]

Adjusting the audible alarm volume is also described on page 33 of the Installation Manual.

The audible alarm can be permanently turned off by removing the jumper from J2 on the control/power center Power Interface Board (PIB).

Cold Water Operation

The display will show the LO code. LO indicates the temperature of Pool is < 54ºF (12.2°C). Chlorine production is stopped.

From Page 39 of the Installation Manual:

Chlorine production is not permitted below 51°F (11°C); operating the chlorinator in cold water might result in over-chlorinated pool water. If more chlorine is needed, activating the “Boost” mode will override this cold water feature allowing chlorine production for 24 hours of operation.

This applies to the Jandy AquaPure and the Nature2 FusionSoft as they are sister products. An optional "Spool" Piece (sold separately) used to be available to replace the cell during winterizing or cell maintenance. This piece has been discontinued and is no longer available. In addition, the AquaPure threads are proprietary, and Jandy does not offer replacement proprietary unions (the "male" piece).

If removing the cell is desired so that water may circulate without the cell, specialized plumbing would need to be added during installation of the cell. One method is an additional PVC union after each end of the cell. This method would require the purchase of 4 unions. 2 for when the cell is installed and 1/2 of the other 2 unions (the "male" 1/2) for the creation of the bypass pipe.

When a FREEZE CONTROLLER is used on pump equipment and the chlorinator is run through the winter, turn the CHLORINE PRODUCTION down to 10 - 20%.

Jandy SP3P Dummy Cell

Jandy has the Jandy SP3P Dummy Cell Cleaning Kit that includes everything you need to remove, clean, store, and/or bypass your Jandy AquaPure 3-Port Salt Cell.

You can remove your cell for winter and install the dummy cell.

AquaPure Cycle Time

The AquaPure has a 3 hour polarity cycle time (3 hours one polarity, 3 hours reverse polarity). The production cycle time used for chlorine production (observationally) is 30 minutes. The percentage setting will control how much the cell runs during the production cycle.[4]

For example, at 50%, the cell will run for 15 minutes and off for 15 minutes. Polarity will change every 3 hours.

Boost – 24 Hour 100% Chlorine Production Cycle.

To Enter Boost Mode Press and Hold “Temperature” Button 10 Seconds

Jandy Warranty

Here is an excerpt from page 423 (892)[5] of their 2019 catalog:[6]

"This Jandy Limited Warranty does not apply to Jandy branded products purchased through the Internet or other e-commerce platforms, with the exception of Jandy branded valves, parts, and accessories. This warranty applies only to products installed and serviced by a contractor who is licensed and qualified in pool equipment by the jurisdiction in which the product will be installed, where such state or local requirements exists. In the event no such state or local requirement exists, the installer and maintainer must be a professional with sufficient experience in pool equipment installation and maintenance."

Here's another item of interest from p 877:

IMPORTANT NOTICE NO WARRANTY if purchased online. This is not a DIY product. Installation by a qualified pool professional required. Register product at Jandy.com/registration.

Jandy Aquapure Parts Replacement

Jandy has changed AquaPure parts over the models' life. If you have an older AquaPure system, you may require a different part to fix your system.

Aquapure Cell Replacement

You should replace the cell, tri-sensor, and power cord when the cell needs replacement. They are sold as a kit.[7]

You will also find the cell sold alone at a lower price than the kit, and it is tempting to buy only the cell. The PLC1400 cell is Jandy P/N R0452400.

The Flow & Salinity Sensor is Jandy P/N R0452500.

The PureLink DC Cord is Jandy P/N R0402800.

Replace the Power Cord When you Replace the Cell

When replacing the cell, it's important to replace the power cord so that the connections are clean and the resistance is minimized.[8]

The prongs are sealed by O-rings and a compression plate held down by two screws. The problem is that the O-rings can leak, creating a corrosive mix of water, salt, hydrogen, and chlorine. This corrosion increases the resistance of the connection and generates a lot of heat due to the high current of 6 to 8 amps.

The center prong is the most common point of failure. You can usually see evidence of a leak when you know to look for it.

Replacing Cracked Aquapure Coupler Union

Jandy uses a proprietary thread on their unions.

Mikeys Quick Coupler sells a Jandy 9000 split union to replace a broken one without cutting the PVC pipe.

Otherwise, you need the Zodiac R0452100 Universal Union Replacement Kit.

You can get this kit, cut out your unions, and glue in a pipe, and then replace the unions...

Jandy Aquapure 3-port Cell Union Kit

Replacing Power Interface Board Assembly (PIB)

Jandy R0984100 Power Interface PCB Large Backboard with Screws for AquaPure and PureLink is used on units manufactured after 12/2007. It replaces the R0467600 PIB used on older units.

Replacing Old Square Jandy PLC700/1400 Cell

Jandy switched to a 3-port cell design to aid in cleaning and plumbing flexibility and no longer makes 2-port cells. However, the Jandy PLC700 cell kit (for pools up to 12,000 gallons) and the PLC1400 (with a 40,000 gallon capacity) kit contain new cells as well as all the necessary accessories to switch a 2-port setup to the new design.[9]

Adjustments to the wiring are:

- Red goes to green, and blue goes to black/white.

- The sensor connects to the same spot. Remove the adapter card if there's a little adapter card between the old sensor cord and the circuit board.

- Look at the label on the CPU for the firmware revision.

- If the power interface board firmware is 02110A10 or 01220A15, you use program A for the tri-sensor. All other firmware uses program B on the tri-sensor inline module.

Replacing Power Center Transformer

Older power centers use a rectangular transformer P/N T1005 that is no longer available. Currently, Jandy has part R0481400, which is the round transformer.

A member found that the new part fit perfectly with the same mounting holes. Even the high-voltage side wires were color-coded identically. The only difference is the new part has a ground wire that was attached to the common ground.[10]

Troubleshooting

The Jandy AquaPure, PureLink & Nature² Fusion Soft Workbook gives a lot of good information on installation and troubleshooting.

Also Jandy AquaPure Troubleshooting.

The voltage tests are a little tricky to do. There are three AC tests and four DC tests. If you don't get the right test points or the meter is not on the correct voltage type, your tests won't be correct.[11]

Pin Corrosion

A common reason the cell fails and gets error codes 120, 121, or 123 is one or more pins corroding and separating from its plate. Most common is the center pin.[12]

You can remove the two screws holding down the plate over the prongs and check the base of the prongs.

The cell cannot be repaired even though the plates may have life left in them.

Some members add dielectric grease to the pins when they do their annual work on the filter and check the cell.

Jandy Aquapure Diagnostic Codes

| CODE | MEANING |

|---|---|

| LO | Water temperature is less than 51 deg. F and chlorine production is stopped |

| BO | Boost cycle has been activated by pressing the ‘Pool Temperature’ key for 10 seconds; it can be canceled by holding the same key for 10 seconds. |

| EC | Aquapure is controlled by an external controller or ORP device. |

| JA | Aquapure is controlled by a Jandy AquaLink RS or PDA, and the system is in AUTO MODE. |

| JO | Aquapure is controlled by a Jandy AquaLink RS or PDA, and the system is in SERVICE or TIME MODE. |

| JB | Aquapure is controlled by a Jandy AquaLink RS or PDA, and the system is in BOOST MODE |

The AquaPure will also display code "dE" that is not documented. Internet posting says the dE code means "Diagnostic mode."[13] Someone posted that Jandy said it means that it has loaded the default settings.[14] You can try holding the up and down arrows simultaneously for about 3 to 5 seconds, and it should reset itself. Otherwise, it seems the back circuit board (R0467600) needed to be replaced.

Jandy Aquapure Error Codes

| Code # | Possible Cause | Solution |

|---|---|---|

| 120 | Low current in forward direction to cell | Clean cell if necessary and check DC cord |

| 121 | Low current in reverse direction to cell | Clean cell if necessary and check DC cord |

| 123 | Extremely low current to cell | Clean cell if necessary and check DC cord |

| 124 | Higher than normal current to cell | Contact a pool professional |

| 125 | Cell needs to be cleaned | Clean cell if necessary |

| 126 | Low current in the forward direction and VAC input voltage below 100-200 VAC | Contact a pool professional |

| 127 | Low current in reverse direction and VAC input voltage below 100-200 VAC | Contact a pool professional |

| 144 | Low Salinity (below 2.0 gpl) | Add salt to pool to achieve 3.0 GPL |

| 145 | High Salinity (above 4.0 gpl) | Backwash filter if a DE filter is installed. Partially drain pool and dilute with fresh water until salinity returns to 3.0 to 3.5 GPL |

| 170 | Possible front board service condition or unit not correctly wired to 120 VAC | Contact a pool professional |

| 171 | Possible backboard service condition | Contact a pool professional |

| 172 | Flow sensor service condition or flow sensor is unplugged | Contact a pool professional |

| 173 | Low VAC input voltage and on board power supply is not regulated or unit not correctly wired Unit wired to improper AC voltage. | Contact a pool professional |

| 174 | Pool temperature is too high for operation of AquaPure Flow/Salinity sensor indicated water temperature at sensor above 108 degrees F. | Reduce water temperature |

| 175 | Flow sensor air lock condition or very low salinity | Verify proper flow/temperature/salinity sensor installation. Check salinity with Myron “L” meter calibrated for NaCl or test strips. Add salt as necessary |

| Code # | Possible Cause | Solution |

|---|---|---|

| 180 | Heated sensor element not heating. (Generates 172 code) | Contact a pool professional |

| 181 | Flow sensor temperature sensor failure. (Generates 172 code – flow sensor service) | Contact a pool professional |

| 182 | Salinity Sensor sees less than 0.2 gpl of salt, no salt in pool or sensor air locked. (Generates 175 code – flow sensor air lock) | Contact a pool professional |

| 183, 184, 185, 186 | Flow salinity sensor temperature probe error codes. (They will all generate 172 codes which indicate flow sensor service is required) | Contact a pool professional |

| 187 | Front board power supply either too low or too high. (Generates 173 – Low input voltage code if Level 2 code 188 is present) (Generates 170 code if 188 is not present) | Contact a pool professional |

| 188 | VAC input voltage is too low. (Generates 173 code if Level II code 187 is present) | Contact a pool professional |

| 189 | Relay not conducting in the forward direction. (Generates 171 code – Backboard service) | Contact a pool professional |

| 190 | Relay not conducting in the reverse direction. (Generates 171code – Backboard service) | Contact a pool professional |

| 191 | High cell current (at upper limit of A/D converter) and cell voltage below 19V. (Generates 170 code front board service) | Contact a pool professional |

| 192 | High cell current and cell voltage below 19V. (generates 171 code – Backboard service) | Contact a pool professional |

| 193 | Measured significant cell current when SCRs were turned off. (Generates 170 code – front board service) | Contact a pool professional |

| 194 | Cell Current is 85% lower than desired and cell voltage above 19V (Generates 125 code – Cell dirty or needs replacement) | Contact a pool professional |

| 195 | Salinity invalid due to out-of-range measurements caused by front board error (Generates 170 code – front board service) | Contact a pool professional |

Error 120

120 is low current. That can be from low salt, low water temperature, a bad power cord, corroded cell plates, or loose power pins. Make sure the temperature is above 60, the salt is 3400, and the power cord is good. Then, look in the cell at the plates with a good light from both ends to see if the plates are corroded.

Error 121

A 121 error can occur for several different reasons: a dirty cell, a damaged cell, a bad cell cable, a low salt level, a cell wearing out due to age, or a damaged power supply.

Test the salt level with a K-1766 Taylor Salt Test.

Error 123

That error is low or no current to the cell. The first thing to check is the cord. Look for heavy corrosion at both ends. You can sometimes fix it by cleaning off the corrosion.[15]

Also, look inside the cell at the cord end. The three pins go inside and connect to the plates. If one is rotted away, it's time for a new cell and cord.

Otherwise, the back circuit board may need replacement.

Cell Amperage

You can check the amperage to verify if the cell is generating. The 700 cell has half the number of plates as the 1400 cell. In this thread, the amperage of the 1400 cell tests at about 5.6 amps, and the amperage of the 700 cell should test at about 2.8 amps.[16]

Burnt Tri-Sensor Center Pin

When the tri-sensor fails, the salinity will be incorrect, or you will get a no-flow error.

Note that the center prong is on the cell where the power cord connects to the cell. This issue is with the tri-sensor, a separate part installed in the cell.

It's usually cheaper to buy the Aquapure 1400 cell kit, which includes the cell, tri-sensor, and power cord, than to buy the parts separately.

If the cell is old, get the PLC1400 kit.

Aquapure Not Taking Aqualink Changes

Aqualink prevents the Aquapure system from proper operation without a functioning water temperature signal from the Aqualink stand-alone water temperature sensor, regardless of what the SWG flow sensor says.

It appears that Aqualink stops talking to Aquapure when the Aqualink water temperature sensor is inoperative.[17]

Changes to Aquapure settings made on Aqualink will not show on the Aquapure, and the chlorine % will be 0.

If the Aquapure is disconnected from the Aqualink, you should be able to set chlorine production from the front panel.

Jandy PDA not displaying AquaPure info

Many AquaPure display problems seem to be fixed by powering the Power Center and Aqualink panel if connected off at the circuit breakers, waiting a few minutes, and powering everything back on.[18]

AquaPure Resets to 35% every time it is Powered On

A member had the problem of his Aquapure resetting to 35% every time the timer powered it on.[19] After discussions with a Jandy representative it was determined the problem was a bad board.

Aquapure Display Garbled

Check the ribbon cable and reboot the system.

Fahrenheit or Celsius Temperature Displayed

When the AquaPure first turns on, the number 60 should be displayed briefly. That is the power supply frequency that the unit detects. If it reads 60 Hz, it assumes the unit is in the US and displays Fahrenheit. If it detects 50 Hz, it will flash 50 on the screen, think it's in Europe, and display Celsius.[20]

AquaPure History

Chloromatic developed the AquaPure system in the 1990's. Jandy acquired Chloromatic in the early 2000's. Chloromatic and early Jandy systems used cells with 2 ports. A design change Jandy made was changing the cell from 2 ports to 3 ports.

- ↑ https://www.troublefreepool.com/threads/need-intelliflo-and-jandy-aquapure-1400-folks.254612/post-2226671y

- ↑ https://www.troublefreepool.com/threads/testing-aqua-pure-salt-cell-is-it-cooked.309133/post-2697978

- ↑ https://www.jandy.com/-/media/zodiac/global/downloads/h/h0325600.pdf

- ↑ https://www.troublefreepool.com/threads/aquapure-cycle-time-wiki-correction.264622/#post-2321916

- ↑ http://viewer.zmags.com/publication/1a29b06c#/1a29b06c/892

- ↑ https://www.troublefreepool.com/threads/when-did-jandy-declare-war-on-diy.176586/post-1558946

- ↑ https://www.troublefreepool.com/threads/plc1400-and-r0452400-compatible.260746/#post-2280305

- ↑ https://www.troublefreepool.com/threads/six-month-old-jandy-plc1400-smoking-melting-rubber-wire-connector.198600/post-1752937

- ↑ https://www.troublefreepool.com/threads/jandy-old-square-salt-cell-replacement.201262/

- ↑ https://www.troublefreepool.com/threads/jandy-power-center-transformer-replacement-aquapure.194422/

- ↑ https://www.troublefreepool.com/threads/error-code-174.99273/post-885060

- ↑ https://www.troublefreepool.com/threads/jandy-aquapure-1400-error-120.236117/

- ↑ https://www.poolspaforum.com/forum/index.php?/topic/50761-jandy-aquapure-system-threw-de-code-now-will-not-operate/

- ↑ https://www.troublefreepool.com/threads/aquapure-de-error-code.111159/post-982198

- ↑ https://www.troublefreepool.com/threads/aquapure-1400-receiving-error-code-123.46288/post-387518

- ↑ https://www.troublefreepool.com/threads/jandy-aquapure-plc-700-not-producing-chlorine.220478/post-1929929

- ↑ https://www.troublefreepool.com/threads/will-a-new-water-temp-sensor-fix-this-aquapure-swg-scenario.243392/

- ↑ https://www.troublefreepool.com/threads/jandy-pda-wasnt-displaying-aquapure-info.194647/post-1715658

- ↑ https://www.troublefreepool.com/threads/aquapure-keeps-resetting-to-chlorine-rate-35-from-pool-pump-timer.197670/post-1743853

- ↑ https://www.troublefreepool.com/threads/error-code-174.99273/post-896321