- Jul 3, 2020

- 111

- Pool Size

- 26000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

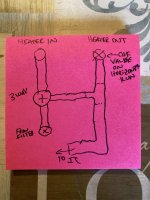

Hi, I have a CMP POOL DEFENDER INLINE SACRIFICIAL ZINC ANODE. I am getting mixed opinions on where to install it on my equipment pad. My heater already has a zinc anode built in, so that takes place for one between filter and heater. I was told by pool store to install my CMP POOL DEFENDER before our pump. Does it matter if I install it before my pump or between my pump and filter?? Thank you!