- Mar 20, 2023

- 250

- Pool Size

- 30000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool Universal40

Bought house in December, still figuring out all the pool stuff.

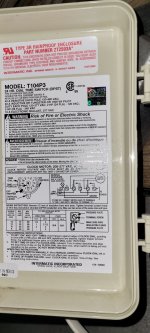

One thing that has/had vexed me is this electrical box. Is fed by the circuit panel. I even had a guy out and he couldn't tell me for sure what it was doing. (He was doing a quote for replacing my old stab-lok style panel. As I have been thinking about it this morning, it is entirely possible that the quote guy they sent may or may not be an electrician...)

Anyway, power goes from the circuit panel (one 15 amp breaker and one 20 amp breaker) into this box. There is a momentary switch on the side of the box. When you push the momentary switch, the magnetic coil is energized to close the connection. And it is kept closed by the power/connection itself being made. Stays connected until, for whatever reason, power is cut to the box. From the box, a single cable goes to the exterior of the house, into a not-great junction box outside, then into the timer, and from there the pump and SWG.

I took another, closer look at the insides of the box this morning. I think what it is doing is combining the two 110v breakers to make a 220v circuit to feed the timer and pump. Looking closely at the Romex cable, I am certain it is 12g wires. It is stamped, not printed but it looks like larger than 14g and I am certain I saw 12 on the jacket. I think the pool setup is old enough that the wiring was done before the jackets were color coded to yellow for 12g.

This is all well and good except for two things:

First, there is not yet any GFCI protection. I was originally thinking I had 120v going to the exterior (based on looking at the jacket before investigating deeper today) and was just going to install a GFCI outlet in that junction box. But now I don't think I can do that.

Second, if there is any sort of blink in power, the electromagnetic connection is broken and power is cut off to the pump and SWG. This happened Saturday night (we were driving home and saw the power blink as we approached a stoplight near the house) and I didn't even think about the electromagnetic connection being broken until I went to manually run the cleaner Sunday evening. Thankfully I went to do that, because it may have been several days otherwise.

That isn't necessarily a giant deal, except for if I don't notice it, or maybe it happened while we were on vacation. We're going to be gone Friday to Monday this weekend.

So that got me to thinking about other remedies.

Looking at the label on my pump, it appears it can be wired to operate off of either 110 or 220. I was thinking I could swap the wiring on the motor and run everything off of one 110 circuit breaker and install a GFCI outlet like I'd planned. But it appears the timer motor only runs on 220 (just looked at a pic I snapped a few weeks ago of the inside door of the timer). Blast!

I suppose I could still do the wiring changes and update the timer to one that would work with 110v?

Or, I do see I could get something like this to add GFCI protection.

The timer and the exterior junction box are under my deck and only accessible outside the pool area which makes things like manually turning the pump on and off to vacuum or empty the skimmer basket inconvenient, so I had been thinking of relocating everything to be inside the pool area.

One benefit of switching everything to 110v is then I could use one of the two pool breakers to run a more proper circuit to my garage, which would be super handy because it is also lacking at the moment. I see that there are actually GFCI breakers available for my stab-lok box, so I could either add GFCI there or by an outlet sending power to everything. (Is the breaker any better/safer than an outlet for any reason, there is a significant price difference.)

Are there any real drawbacks to wiring the pump to run on 110v? I do recall asking a friend about 110v vs. 220v on my air compressor and he said that it will consume more power at 110v. True? How much more? I wasn't worried about that with the air compressor, but it does seem like a consideration with the pool pump.

Do my suspicions of what this box is doing (taking two 110v circuits to make one 220v circuit) seem correct?

What are my real options to improve all this (e.g. adding GFCI and not having to worry about power accidentally getting cut and not realizing it) without spending an arm and a leg for a full panel replacement at this time? (I would like to have that done at some point down the road.)

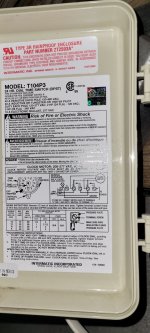

Second pic is just the label on the electromagnetic device.

One thing that has/had vexed me is this electrical box. Is fed by the circuit panel. I even had a guy out and he couldn't tell me for sure what it was doing. (He was doing a quote for replacing my old stab-lok style panel. As I have been thinking about it this morning, it is entirely possible that the quote guy they sent may or may not be an electrician...)

Anyway, power goes from the circuit panel (one 15 amp breaker and one 20 amp breaker) into this box. There is a momentary switch on the side of the box. When you push the momentary switch, the magnetic coil is energized to close the connection. And it is kept closed by the power/connection itself being made. Stays connected until, for whatever reason, power is cut to the box. From the box, a single cable goes to the exterior of the house, into a not-great junction box outside, then into the timer, and from there the pump and SWG.

I took another, closer look at the insides of the box this morning. I think what it is doing is combining the two 110v breakers to make a 220v circuit to feed the timer and pump. Looking closely at the Romex cable, I am certain it is 12g wires. It is stamped, not printed but it looks like larger than 14g and I am certain I saw 12 on the jacket. I think the pool setup is old enough that the wiring was done before the jackets were color coded to yellow for 12g.

This is all well and good except for two things:

First, there is not yet any GFCI protection. I was originally thinking I had 120v going to the exterior (based on looking at the jacket before investigating deeper today) and was just going to install a GFCI outlet in that junction box. But now I don't think I can do that.

Second, if there is any sort of blink in power, the electromagnetic connection is broken and power is cut off to the pump and SWG. This happened Saturday night (we were driving home and saw the power blink as we approached a stoplight near the house) and I didn't even think about the electromagnetic connection being broken until I went to manually run the cleaner Sunday evening. Thankfully I went to do that, because it may have been several days otherwise.

That isn't necessarily a giant deal, except for if I don't notice it, or maybe it happened while we were on vacation. We're going to be gone Friday to Monday this weekend.

So that got me to thinking about other remedies.

Looking at the label on my pump, it appears it can be wired to operate off of either 110 or 220. I was thinking I could swap the wiring on the motor and run everything off of one 110 circuit breaker and install a GFCI outlet like I'd planned. But it appears the timer motor only runs on 220 (just looked at a pic I snapped a few weeks ago of the inside door of the timer). Blast!

I suppose I could still do the wiring changes and update the timer to one that would work with 110v?

Or, I do see I could get something like this to add GFCI protection.

The timer and the exterior junction box are under my deck and only accessible outside the pool area which makes things like manually turning the pump on and off to vacuum or empty the skimmer basket inconvenient, so I had been thinking of relocating everything to be inside the pool area.

One benefit of switching everything to 110v is then I could use one of the two pool breakers to run a more proper circuit to my garage, which would be super handy because it is also lacking at the moment. I see that there are actually GFCI breakers available for my stab-lok box, so I could either add GFCI there or by an outlet sending power to everything. (Is the breaker any better/safer than an outlet for any reason, there is a significant price difference.)

Are there any real drawbacks to wiring the pump to run on 110v? I do recall asking a friend about 110v vs. 220v on my air compressor and he said that it will consume more power at 110v. True? How much more? I wasn't worried about that with the air compressor, but it does seem like a consideration with the pool pump.

Do my suspicions of what this box is doing (taking two 110v circuits to make one 220v circuit) seem correct?

What are my real options to improve all this (e.g. adding GFCI and not having to worry about power accidentally getting cut and not realizing it) without spending an arm and a leg for a full panel replacement at this time? (I would like to have that done at some point down the road.)

Second pic is just the label on the electromagnetic device.

But it is good to know for sure.

But it is good to know for sure.