- Jul 29, 2017

- 75

- Pool Size

- 24000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Turbo Cell (T-CELL-5)

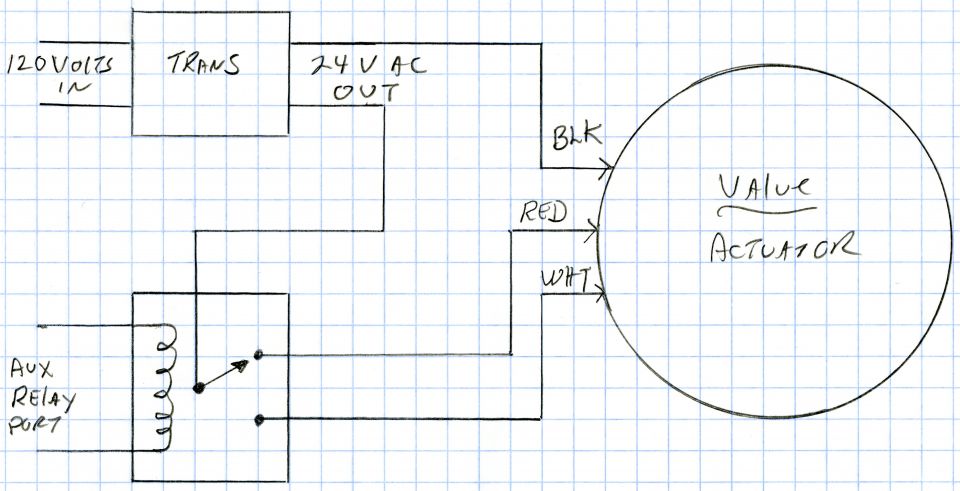

Do I have this right? There is a single motor which runs forward with standard polarity and reverse with reverse polarity. When it reaches its desired terminus the mechanical switch interrupts the power on the lead turning the valve. At more or less the same time it closes the mechanical switch for opposite polarity so that when it gets a signal to turn back it can. If the actuator gets a signal to move to position B and it is already in position B then nothing happens because that circuit is already interrupted by the mechanical switch. If it gets a signal to move to the opposite position "A" then it will turn to A. Do I have this right?

The reason I am asking is I am going to replace my automation and plan to have a number of macros. I think hayward or pentair call them themes. I am making some plumbing changes in advance and want to plan accordingly. If I schedule a change from one macro to another and it changes an intake valve but may or may not need to change a return valve can I count on the automation getting the valves to the right spot independent of what position the valves are in when the macro comes on and even if there are, lets say, three or four valves that need positioning.

Thanks in advance.

Chris

The reason I am asking is I am going to replace my automation and plan to have a number of macros. I think hayward or pentair call them themes. I am making some plumbing changes in advance and want to plan accordingly. If I schedule a change from one macro to another and it changes an intake valve but may or may not need to change a return valve can I count on the automation getting the valves to the right spot independent of what position the valves are in when the macro comes on and even if there are, lets say, three or four valves that need positioning.

Thanks in advance.

Chris