So, I just had the local pool service guy over to replace my second heater in under two years.

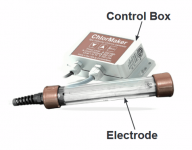

The first heater was probably/definitely because I started the spa dry during a water change like a moron a while back, but this one doesn't make a lot of sense. The service guy said it was probably because it's a saltwater tub, because the heating element and heat exchanger tube itself was significantly corroded. However, my understanding is that the level of salt in my water (1500 ppm with a Chlormaker) is unlikely to cause issues unless the pH gets low. My pH sits at 7.6-8.0 like a rock, and tends to slowly climb due to aeration. I've got about 190-200 ppm calcium, 60 ppm borates, and probably 18-20 ppm CYA.

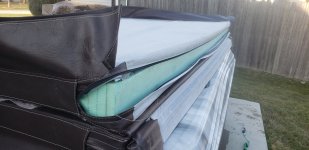

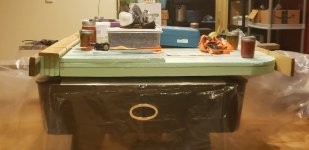

I've had some issues controlling the swcg cell, which boil down to the fact that I was trying to run it with the cell tucked into the center of one of the return filters like a Nature 2 Mineral stick. The flow rates were either too high or too low and the chlorine levels inside the filter wouldn't reflect the bulk water of the tub, so would bounce around uncontrollably. Basically, I was manufacturing a bunch of headaches due to my insistence on placing the cell there. I think it may also be the source of the heater failure as well, combined with one other issue. By placing the cell at the water return, I was piping the high chlorine concentration from the cell directly through the circ system and the heater, which would seem to be undesirable in this light, correct? Chlorine being an aggressive oxidizer and all that? In addition to that, recently I had some bad luck with my cover when a huge mass of snow slid off of my roof on two separate occasions and smashed the structural integrity out of half of my spa cover, fully cracking and destroying one side. I have since replaced the insulation with a DIY foam pack I built up out of closed cell XPS insulation from Lowes and fit into the vinyl cover jacket, but I suspect it may still be a bit leakier than the original cover. This could lead to the heater running more than usual, causing more rapid corrosion.

I have discontinued placing the salt cell in the filter, and have been much more successful at keeping the chlorine levels steadily healthy, but that change was fairly recent, so high chlorine levels and chlorine direct injection into the heater remains my active hypothesis for the premature failure of the heater.

Any other possibilities I may be missing? We're pretty late on changing the water out right now, so maybe have a lot of stuff dissolved in there, would that be a problem? I know for a fact that the salt is still below 1600 ppm though.

Should I have my CYA levels higher? I was under the impression that spas didn't need much since they don't see the sun much, so I've always targeted 20 CYA as enough to buffer the chlorine but keep it easy to shock if necessary. That would make the chlorine more aggressive on the heater if it gets high though, wouldn't it?

The first heater was probably/definitely because I started the spa dry during a water change like a moron a while back, but this one doesn't make a lot of sense. The service guy said it was probably because it's a saltwater tub, because the heating element and heat exchanger tube itself was significantly corroded. However, my understanding is that the level of salt in my water (1500 ppm with a Chlormaker) is unlikely to cause issues unless the pH gets low. My pH sits at 7.6-8.0 like a rock, and tends to slowly climb due to aeration. I've got about 190-200 ppm calcium, 60 ppm borates, and probably 18-20 ppm CYA.

I've had some issues controlling the swcg cell, which boil down to the fact that I was trying to run it with the cell tucked into the center of one of the return filters like a Nature 2 Mineral stick. The flow rates were either too high or too low and the chlorine levels inside the filter wouldn't reflect the bulk water of the tub, so would bounce around uncontrollably. Basically, I was manufacturing a bunch of headaches due to my insistence on placing the cell there. I think it may also be the source of the heater failure as well, combined with one other issue. By placing the cell at the water return, I was piping the high chlorine concentration from the cell directly through the circ system and the heater, which would seem to be undesirable in this light, correct? Chlorine being an aggressive oxidizer and all that? In addition to that, recently I had some bad luck with my cover when a huge mass of snow slid off of my roof on two separate occasions and smashed the structural integrity out of half of my spa cover, fully cracking and destroying one side. I have since replaced the insulation with a DIY foam pack I built up out of closed cell XPS insulation from Lowes and fit into the vinyl cover jacket, but I suspect it may still be a bit leakier than the original cover. This could lead to the heater running more than usual, causing more rapid corrosion.

I have discontinued placing the salt cell in the filter, and have been much more successful at keeping the chlorine levels steadily healthy, but that change was fairly recent, so high chlorine levels and chlorine direct injection into the heater remains my active hypothesis for the premature failure of the heater.

Any other possibilities I may be missing? We're pretty late on changing the water out right now, so maybe have a lot of stuff dissolved in there, would that be a problem? I know for a fact that the salt is still below 1600 ppm though.

Should I have my CYA levels higher? I was under the impression that spas didn't need much since they don't see the sun much, so I've always targeted 20 CYA as enough to buffer the chlorine but keep it easy to shock if necessary. That would make the chlorine more aggressive on the heater if it gets high though, wouldn't it?

Last edited: