- Aug 23, 2017

- 109

- Pool Size

- 17700

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

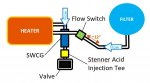

First off I will say that I love my stenner pump, and like having autopilot for the pilot. I don’t even really mind filling up the tank and logging the bottles. My issue is COVID and the increased cost and lack of availability of liquid chlorine. I can imagine it’s only going to get worse as summer approaches. I’d like to make the switch to a SWCG but the plumbing confounds me as my pad is very “efficient”, as in quite compact. To play nice with my automation I know I need a Hayward cell, and likely the extended cell for 40k gallon pools (my pool is roughly 18k). I even already have the Taylor salt test and my pool is already like -2500ppm to start. I’m sure I can do the plumbing myself, but need ideas on how to plumb it. There’s very little footage of pump between the heater and the spa valves. You can see where I have my stenner plumbed in. Below is a pic of my pad and appreciate all suggestions.