Sorry for not having a signature yet, but I wanted to chime in on how useful this thread has been and give a summary of my working setup (thanks to the information here and in

This related thread that's been linked a number of times)

Pump: Super Max VS (RS-485 compatible, manufactured 2022)

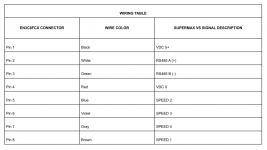

Cable:

Switchcraft CAEN3C8F07990

Controller:

Zooz Zen16 Relay (Connected to SmartThings)

Ironically, even though my cable and pump WOULD support RS-485 comms, I didn't bother trying to find a setup to support this.

I wired up the digital inputs using the Pump's output signal (5v) chained to my 3 relays according to the diagram in the SuperMax VS manual.

The main difference is that I omitted speed 1 / relay 1 and used my 3 available relays to control the "functioning" speeds (2,3, and 4 -- as speed 1 needs to be set to 0 RPM anyway).

I control this "Off" state using the Zen16's on/off functionality -- in SmartThings and other zwave hubs, this device shows up as 4 devices (1 controller with all the advanced settings, and 3 relays). When the "Controller" device is turned off, it functions as a sort of 4th relay, cutting all of the 5v signals returning to the digital inputs and defaulting to speed 1 (which is, of course, 0 or OFF).

I haven't gotten into any scheduling / programming but the Zen16 has lots of functionality, you can connect external inputs that correlate to the 3 relays, set the "mode" of those switches to be momentary, toggle, etc... and with smartthings (or any zwave controller) you can set schedules, bypass the switches, and control everything remotely.

The "missing" element here is the ability to modify RPMs of the 3 speeds beyond what's programmed at the pump's controller. But realistically, once I figure out what 3 speeds are required for my needs, I don't anticipate touching the RPMs ever.

What's nice about this setup is that for ~100$ CAD (between the cable and relay) I've got all the functionality I need -- I can program control and automation through my existing smartthings setup, control remotely, or use the smartthings web interface.

--------------------------

If anyone needs information on the appropriate Zen16 device settings I am using, let me know.