Received my RJ-45+, and reading the manual now. It calls out FC target = 1.0 - 3.0 ppm for CYA = 30 - 50, or roughly 5% average. Pool Math tells me 5.0 - 10.0 for CYA = 60, or roughly 12.5% average, 2.5x higher than CircuPool. Even the bottom of the range in pool math = 5/60 = 8.3%, whereas bottom of range from Circupool = 1/50 = 2%.

What am I missing?

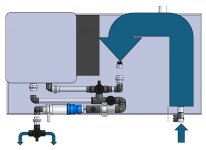

edit: Further reading in the same manual, I find what I believe to be their reasoning: "This form of chlorine works quickly in the pipe, leaving only a mild residual in the pool. In addition, the Electrolytic Cell continuously “shocks” the incoming water- burning off any oils, organic matter, or other particles that need to be oxidized." So, much higher FC levels in the plumbing, outlet side of RJ cell, but lower FC measured in the pool. Conversely, when I'm adding liquid chlorine, it's just that level everywhere.

What am I missing?

edit: Further reading in the same manual, I find what I believe to be their reasoning: "This form of chlorine works quickly in the pipe, leaving only a mild residual in the pool. In addition, the Electrolytic Cell continuously “shocks” the incoming water- burning off any oils, organic matter, or other particles that need to be oxidized." So, much higher FC levels in the plumbing, outlet side of RJ cell, but lower FC measured in the pool. Conversely, when I'm adding liquid chlorine, it's just that level everywhere.

Last edited: