Does the SWG unit work appropriately if the flow direction is changed? The SWG will always be on the downstream side of pumps and filters, but I want to place it where flow will sometimes be reversed. I have both a DE filter and a sand filter, each with their own dedicated pump. The DE filter is in service most of the summer, but I switch to the sand filter in the fall and spring when the chunkier stuff starts hitting the pool. The best spot to install an SWG will see different flow directions depending on which pump/filter is being utilized

SWG flow direction requirement

- Thread starter TooMuchPool

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Jul 21, 2013

- 65,069

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Welcome to TFP.

What model SWG are we discussing?

Almost all SWGs use a flow switch. Water should only flow in one direction for the flow switch to operate properly.

What model SWG are we discussing?

Almost all SWGs use a flow switch. Water should only flow in one direction for the flow switch to operate properly.

For that application, it should be in the last pipe, one that gets flow from either filter, going into the ground and back to the pool.Does the SWG unit work appropriately if the flow direction is changed? The SWG will always be on the downstream side of pumps and filters, but I want to place it where flow will sometimes be reversed. I have both a DE filter and a sand filter, each with their own dedicated pump. The DE filter is in service most of the summer, but I switch to the sand filter in the fall and spring when the chunkier stuff starts hitting the pool. The best spot to install an SWG will see different flow directions depending on which pump/filter is being utilized

I haven’t narrowed down a specific model. If I can only utilize it with one filter/flow direction, it may not be worthwhile for meWelcome to TFP.

What model SWG are we discussing?

Almost all SWGs use a flow switch. Water should only flow in one direction for the flow switch to operate properly.

Correct, I have a decent spot downstream of both pumps that would work well…if reverse flow was acceptableFor that application, it should be in the last pipe, one that gets flow from either filter, going into the ground and back to the pool.

- Jul 21, 2013

- 65,069

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

I just noticed you have a 68,000 gallon pool.I haven’t narrowed down a specific model. If I can only utilize it with one filter/flow direction, it may not be worthwhile for me

We recommend a SWG be 2X the pool volume. You need a SWG setup that gives you about 120K generation capacity. That limits you to a few commercial multiple cell SWG's. All those SWGs use a flow switch.

A Pentair Comsys-2 would use two IC60 cells and give you 120K capacity.

IntelliChlor® Salt Chlorine Generator for Commercial Pools

View the Commercial Pool Water Treatment and Sanitizers offering from Pentair here. From Chlorine Feeders to Generators, Pentair has your commercial pool needs covered.

SWG Multiple Cells - Further Reading

The cell in most SWG systems "doesn't care" which way the water is going through it. A flow switch does.Does the SWG unit work appropriately if the flow direction is changed? The SWG will always be on the downstream side of pumps and filters, but I want to place it where flow will sometimes be reversed. I have both a DE filter and a sand filter, each with their own dedicated pump. The DE filter is in service most of the summer, but I switch to the sand filter in the fall and spring when the chunkier stuff starts hitting the pool. The best spot to install an SWG will see different flow directions depending on which pump/filter is being utilized

- Feb 6, 2015

- 7,807

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

Post a few pics of your equipment pad from a few different angles so we can see what you're working with.

Label the pipes to make it easier to see the flow in the pics.

As for the flow switch - water can only flow thru it in one direction to activate the switch. Additionally, the flow switch must be in a horizontal pipe or if a vertical pipe, the water flow must be upwards.

Label the pipes to make it easier to see the flow in the pics.

As for the flow switch - water can only flow thru it in one direction to activate the switch. Additionally, the flow switch must be in a horizontal pipe or if a vertical pipe, the water flow must be upwards.

You scared me quite a bit when you said commercial, those units are incredibly expensive! I believe what you are suggesting is installing 2 IC60 units in parallel, which is more or less what I concluded based on research here at TFPI just noticed you have a 68,000 gallon pool.

We recommend a SWG be 2X the pool volume. You need a SWG setup that gives you about 120K generation capacity. That limits you to a few commercial multiple cell SWG's. All those SWGs use a flow switch.

A Pentair Comsys-2 would use two IC60 cells and give you 120K capacity.

IntelliChlor® Salt Chlorine Generator for Commercial Pools

View the Commercial Pool Water Treatment and Sanitizers offering from Pentair here. From Chlorine Feeders to Generators, Pentair has your commercial pool needs covered.www.pentair.com

SWG Multiple Cells - Further Reading

www.troublefreepool.com

It’s not often I can share this madness with other knowledgeable pool folks, so here you go ha ha. After further thought, there is a single direction flow location, regardless of which filter is running. Not much of an existing straight run of pipe thoughPost a few pics of your equipment pad from a few different angles so we can see what you're working with.

Label the pipes to make it easier to see the flow in the pics.

As for the flow switch - water can only flow thru it in one direction to activate the switch. Additionally, the flow switch must be in a horizontal pipe or if a vertical pipe, the water flow must be upwards.

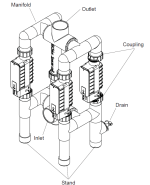

Attachments

- Feb 6, 2015

- 7,807

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

Well, that's an interesting plumbing setup.

Not sure if that one way (regardless of which filter is active) pipe is long enough to accommodate the SWG flow switch and cell horizontally, but you can always do a vertical install in that pipe run. As long as that run is after both filters and the heater, it should work. The SWG and flow switch needs to be the last piece of equipment before the water returns to the pool.

Not sure if that one way (regardless of which filter is active) pipe is long enough to accommodate the SWG flow switch and cell horizontally, but you can always do a vertical install in that pipe run. As long as that run is after both filters and the heater, it should work. The SWG and flow switch needs to be the last piece of equipment before the water returns to the pool.

I would start with one IC60 and see how it does.

If you run 24/7, it will probably keep up.

Your main pump should be a variable speed pump so that it can be run at lower speeds 24/7.

If you have to, you can add a second power box and a second cell in series with the first cell.

You can use parallel cells, but that requires more flow.

There is no reason to use commercial units.

There is no reason that the units need to be coordinated.

Just run the second cell in series up to 100% and then add percentage to the first cell as needed.

If you turn on the second cell, maybe increase the flow by about 10 gpm.

You can install both units at the same time if that is easier, but I suspect that one cell will keep up.

If you run 24/7, it will probably keep up.

Your main pump should be a variable speed pump so that it can be run at lower speeds 24/7.

If you have to, you can add a second power box and a second cell in series with the first cell.

You can use parallel cells, but that requires more flow.

There is no reason to use commercial units.

There is no reason that the units need to be coordinated.

Just run the second cell in series up to 100% and then add percentage to the first cell as needed.

If you turn on the second cell, maybe increase the flow by about 10 gpm.

You can install both units at the same time if that is easier, but I suspect that one cell will keep up.

Last edited:

An IC60 should provide about 3.5 ppm fc, which should be enough for most days if everything is managed correctly including keeping the CYA at 60 to 80 and the fc in the 6 to 12 range (FC/CYA =10% to 15%).

Although we recommend that a SWG should be sized at twice the pool size, it is not necessary, especially when the pool will require two units or commercial units.

You can supplement with liquid chlorine if necessary, but I suspect that it will not be necessary.

Your UV does look to be very high from the PVC turning brown, which happens in intense UV in places like Arizona, Texas etc.

Although we recommend that a SWG should be sized at twice the pool size, it is not necessary, especially when the pool will require two units or commercial units.

You can supplement with liquid chlorine if necessary, but I suspect that it will not be necessary.

Your UV does look to be very high from the PVC turning brown, which happens in intense UV in places like Arizona, Texas etc.

- Jul 21, 2013

- 65,069

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

If you go with IntelliChlor cells the flow switch is integrated with the cell and you do not have a choice on positioning the flow switch differently then the cell.

I would do two cells in parallel. Not much added cost in the overall scheme of things to have adequate chlorine generation.

You run one cell set at 90% and then vary the other cell % to dial in the needed chlorine.

I would do two cells in parallel. Not much added cost in the overall scheme of things to have adequate chlorine generation.

You run one cell set at 90% and then vary the other cell % to dial in the needed chlorine.

- Jul 21, 2013

- 65,069

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

So put them in series.Double the flow requires 6 to 8 times the power.

Parallel gives zero benefit.

Really does not make a difference.

Series will require about 25 gpm and 200 watts.

Parallel will require about 50 gpm and 1,200 watts.

In my opinion, one cell will keep up.

You can always add a second cell and power supply later.

The cells do not need to be coordinated.

One cell can be operated by the Pentair Automation and the second one can be operated from the control panel on the cell.

Both can be powered from the Filter Pump Relay Load Terminals.

If you have 2 cells, operate the second cell up to maximum percentage before turning on the first cell.

Operating the second cell in series reduces any potential interference with operation of the first cell.

In my opinion, two cells in series will not significantly interfere with the production.

In my opinion, it would take a lot of cells in series to begin to create a significant amount of interference with the production of chlorine.

I would limit the number of cells in series to three, but I don't have any good reason for that number.

Parallel will require about 50 gpm and 1,200 watts.

In my opinion, one cell will keep up.

You can always add a second cell and power supply later.

The cells do not need to be coordinated.

One cell can be operated by the Pentair Automation and the second one can be operated from the control panel on the cell.

Both can be powered from the Filter Pump Relay Load Terminals.

If you have 2 cells, operate the second cell up to maximum percentage before turning on the first cell.

Operating the second cell in series reduces any potential interference with operation of the first cell.

In my opinion, two cells in series will not significantly interfere with the production.

In my opinion, it would take a lot of cells in series to begin to create a significant amount of interference with the production of chlorine.

I would limit the number of cells in series to three, but I don't have any good reason for that number.

- Jul 21, 2013

- 65,069

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Six cells in series.

autopilot.com

autopilot.com

Pool Pilot® Professional - AutoPilot Website

Part #: PRO2US, PRO3US, PRO4US, PRO5US, and PRO6US Versatile chlorine generator that can be sized for any commercial pool. Produces up to 15.72 lbs. of chlorine per day. The Professional unit offers luxurious water and so much more! Eliminates chlorine storage Reduce pH problems Slash chemical...

Pentair only has 2 cells in series.

The 8 cell model has 4 sets of 2 in series in parallel.

In any case, 2 cells in series should be fine.

The 8 cell model has 4 sets of 2 in series in parallel.

In any case, 2 cells in series should be fine.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.