I am looking to install the Pentair I9 Intellitouch (125 amp)sub panel. I will run about 60ft from main panel through attic/floor joist, then the last 20ft outside to a stand alone panel board. I have read many threads but still not clear on requirements.

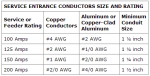

If I want the full 125 Amp available what size wire?

Does it all need to be in conduit or just the outside part.

Thanks i advance for the help?

If I want the full 125 Amp available what size wire?

Does it all need to be in conduit or just the outside part.

Thanks i advance for the help?