Here are some photos and a dropbox link to a video of the cycle. Sorry my voice is a bit muffled. IMG_1240.MP4

Sta-Rite Max-E-Therm Will Not Light No Error Codes

- Thread starter jamescodling

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I removed the bottom bolt completely while the pump was running. No water at all.Did you actually remove the bottom bolt?

You need to check the gas pressure before firing as as the heater tries to fire.

mguzzy

Gold Supporter

Yeah I could smell a puff of gas when the main valve opened, and a click (the main valve), but the regulator valve never opened and so it would shut down the gas flow. If its the solenoid, they are easy to test with an ohm meter. just check and see if the coils are shorted to start off with. But I didn't know what I was looking for on mine and I pulled the whole gas valve out and cleaned like I was working on a carburetor. It was after I reassembled it I could see one of the valves wasn't opening.I can smell gas which tells me gas is making it through the valve and out the vent by force of the blower. I can't see how I would be able to smell gas if the valve wasnt opening? Thoughts?

Through process of elimination I addressed everything but the valve. Sta-Rite tech support stopped short of troubleshooting the gas valve, and the company that makes the valves won't service them..they just tell you to replace it.. so I did what my daddy always said.. "it's already broke, so you won't make it worse by trying to fix it. "

The blower doesn't sound right. Is it even running? Can you feel suction on the intake or air coming out of the exhaust?

Yes on both accounts. I was thinking of taking it apart. We did have rodents a few years ago and maybe they left some gems inside. It has been working fine though but the unit was incredibly dirty.

Ahh ok, I'll check that!Yeah I could smell a puff of gas when the main valve opened, and a click (the main valve), but the regulator valve never opened and so it would shut down the gas flow. If its the solenoid, they are easy to test with an ohm meter. just check and see if the coils are shorted to start off with. But I didn't know what I was looking for on mine and I pulled the whole gas valve out and cleaned like I was working on a carburetor. It was after I reassembled it I could see one of the valves wasn't opening.

Through process of elimination I addressed everything but the valve. Sta-Rite tech support stopped short of troubleshooting the gas valve, and the company that makes the valves won't service them..they just tell you to replace it.. so I did what my daddy always said.. "it's already broke, so you won't make it worse by trying to fix it. "

mguzzy

Gold Supporter

Just watched your vid.. that looks eerily similar to my issue. Once the 3 flashes start on the Fenwal there is an ignition lockout and nothing is going to lite. Current to the ignitor is shut off. Eventually the service light would come on and then the heater would power off like a normal shut down (in my case). Also I bet if you turn over the circuit board on the controller there will be no diag lights. Those diag lights will give you an insight into other things that could be causing the ignition lockout. If there are none.. then everything else is likely working as it should.

- Oct 25, 2015

- 5,823

- Pool Size

- 28000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

If you open a line a that has no flow and has previously has flow it will still smell like gas. The mercaptans used as odorants are incredibly persistent. Check for flow and pressure to be sure you have gas not just smell.I can smell gas which tells me gas is making it through the valve and out the vent by force of the blower. I can't see how I would be able to smell gas if the valve wasnt opening? Thoughts?

Chris

THat's exactly what mine is doing.. Multimeter out! I'll give it a test.Just watched your vid.. that looks eerily similar to my issue. Once the 3 flashes start on the Fenwal there is an ignition lockout and nothing is going to lite. Current to the ignitor is shut off. Eventually the service light would come on and then the heater would power off like a normal shut down (in my case). Also I bet if you turn over the circuit board on the controller there will be no diag lights. Those diag lights will give you an insight into other things that could be causing the ignition lockout. If there are none.. then everything else is likely working as it should.

swamprat69

Well-known member

I see you are correct...musta been someone else that I was helping with a different heaterSwamp,

Thanks for chiming in, I should have called you in as you were so helpful in my previous heater problems. One question when you mention metal screen are you talking about the part inside the flame holder (#11)? Mine did not have this. Only the flame tube and the igniter was in a separate opening beside the flame tube mounted a few inches away in the lid. The more I look at this it definitely looks a lot different from mine. Not sure if this makes any difference in the diagnosis or fix. Just want to learn the max I can from you.

Chris

All values were between 17 and 100 ohms so sounds like valve is good. I will get a manometer I guess is next step to be sure of flow.THat's exactly what mine is doing.. Multimeter out! I'll give it a test.

- Oct 25, 2015

- 5,823

- Pool Size

- 28000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

Sorry I missed the video until just now. You definitely have a gas/air mixture supply problem if you are certain the igniter is heating. Are you not smelling gas in the vent for a brief time during the blower operation? If not, then you have a gas supply problem to the fire box. This is most likely:

Chris

- Supply to the gas valve in the heater.

- Gas valve has an internal obstruction or solenoid is opening but not opening the gas valve.

Chris

After the valve clicks I am smelling gas for a brief second. I'll run down a manometer online and rule the supply issue out. I did check all of the solenoids with ohmmeter and they tested under 100 ohms.Sorry I missed the video until just now. You definitely have a gas/air mixture supply problem if you are certain the igniter is heating. Are you not smelling gas in the vent for a brief time during the blower operation? If not, then you have a gas supply problem to the fire box. This is most likely:

There are ways to check for adequate gas and flow without a digital manometer or a home made manometer but they are not safe so I won't go into them. You really need a manometer or a gas plumber. You can easily make one with tubing that I've tested and used myself. Took about an hour to make.

- Supply to the gas valve in the heater.

- Gas valve has an internal obstruction or solenoid is opening but not opening the gas valve.

Chris

mguzzy

Gold Supporter

I presume you disconnected the leads to the solenoids when you tested it. Yes? James mentioned there are little ports on the side where you can check for gas on the inlet and outlet side. they are little set screws. I never fussed with those but they might give you some insight as to whether gas is making it through the valve.... I pulled my old valve out for reference. I can send you a pic if you want.All values were between 17 and 100 ohms so sounds like valve is good. I will get a manometer I guess is next step to be sure of flow.

Yes please do, I would appreciate it! And yes I removed the leads before testingI presume you disconnected the leads to the solenoids when you tested it. Yes? James mentioned there are little ports on the side where you can check for gas on the inlet and outlet side. they are little set screws. I never fussed with those but they might give you some insight as to whether gas is making it through the valve.... I pulled my old valve out for reference. I can send you a pic if you want.

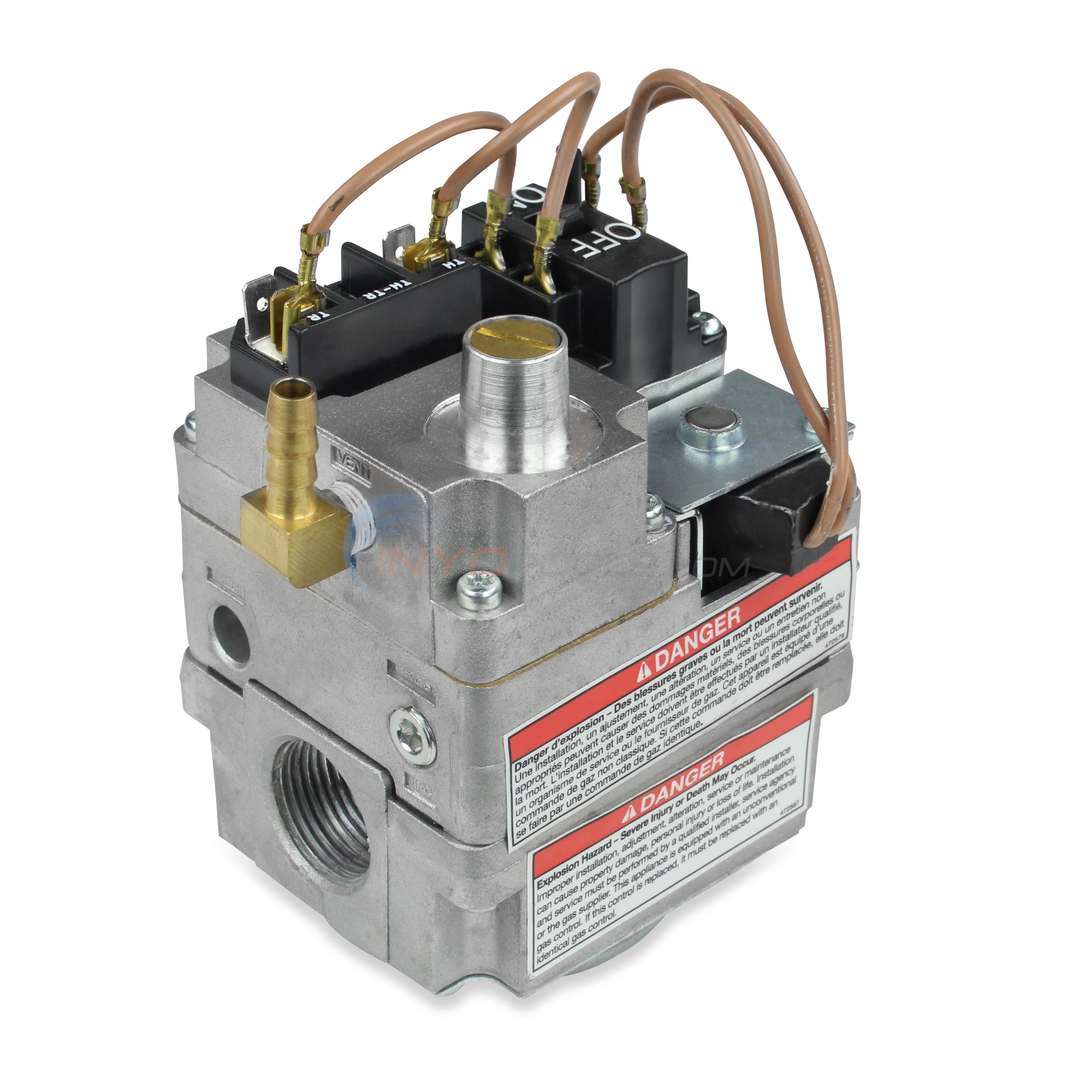

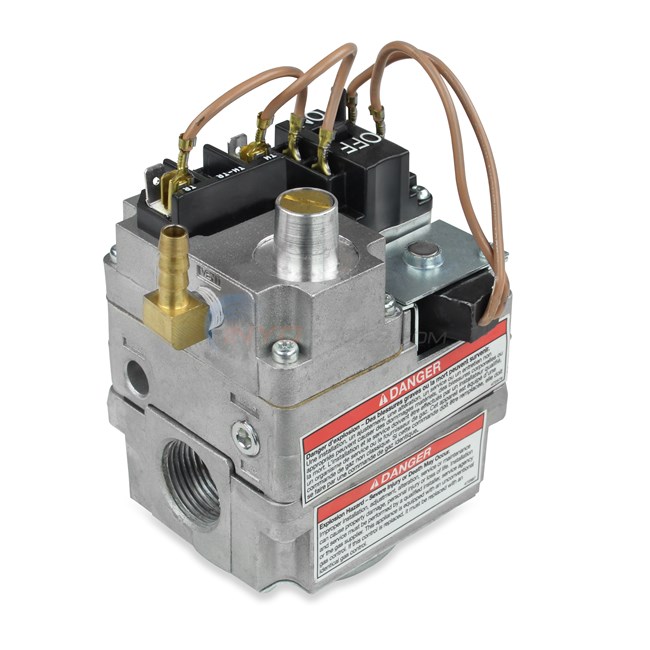

Pentair Heater Combination Gas Control Valve Kit - 42001-0051S - INYOPools.com

42001-0051S - COMBINATION GAS CONTROL VALVE KIT (42001-0051S)

The inlet pressure tap can be used to check the inlet gas pressure before and during attempt to ignite. Pressure should be between 4" to 14" water column at all times.

The manifold pressure tap can be used to check the manifold pressure. It should be -0.2 +/- 0.1 inches of water column.

You cannot use a slack tube manometer to check the manifold gas pressure since it is negative.

You have to use a digital differential pressure gauge.

The procedure is shown in the manual.

The pressure tap set screw uses an Allen wrench. It's a 1/8" npt thread. You have to install a T in one tube and connect it to one port of a two port digital manometer.

The other port connects to the pressure tap as shown in the manual.

You're measuring the differential pressure between the vent line (brass fitting) and the pressure tap port below and to the right of the brass fitting.

You will need a T that will fit in the tubing, some spare tubing, and a 1/8" npt threaded x barbed brass tubing fitting that you can use in the pressure tap port.

Note: Don't do anything that you're not sure that you can do safely.

Last edited:

mguzzy

Gold Supporter

Here is a breakdown of my valve. I ended up buying a used one for 50bux off eBay and stealing the regulator side solenoid off it. This is the "good used" one I got. So this should be a functioning valve (except for the solenoid). I figured I would send you these pics and you can decide how adventurous you want to get. I originally pulled mine apart thinking something crawled inside and was clogging one the little pathways. It was like working on a carburetor, so I used carburetor cleaner to flush out the various ports and pathways. I would try JamesW procedure first for testing the inlet and outlet flow first so you don't have to disassemble the whole mess.

- Oct 25, 2015

- 5,823

- Pool Size

- 28000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

I made the tube manometer to test supply pressure and verified it was good. Then as James mentioned I had to get a digital manometer to deal with the negative pressure to test and adjust differential. Mine needed adjustment but didn't solve the problem. If you have pressure to the gas valve I expect your problem will be proven to be the gas valve differential test. When I shopped for the digital manometer I found a huge range in price; I bought one for about $35 that worked great. I got the 1/8" tee that James described at Loews. Worked great.

I think you're getting close. Please do keep us appraised!

Chris

I think you're getting close. Please do keep us appraised!

Chris

I wonder if it's better to just got one off of ebay.. looks like under $100 bucks for the pipe and the valve! I cannot imagine there being a supply side gas issue.. Nothing has changed at all, it just stopped working one day. Thoughts?

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.