- Feb 22, 2022

- 101

- Pool Size

- 18500

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-20

We used leuders limestone for our pool coping. I live in Texas where it can get to 105 for months with no rain.

4 months after our pool completion, our limestone started spalling. At that time we had freezing temps, which causes spalling. At this time I had a chlorine puck pool. After about a year I converted to a SWG. It’s gotten worse since the SWG, but I don’t know if that’s the cause.

I did not initially seal the coping, but once is started spalling I sealed it 3 times with stone tech salt water sealant.

The coping is getting worse and worse. I need to replace it.

I’m curious if sealing all sides of limestone before installing would work or if I need a new coping altogether? I’ve read about Oklahoma stone, but it doesn’t fit our pool look.

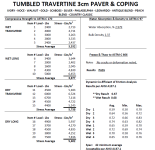

Please let me know if new limestone sealed would work or if I need new coping, what kind should I install?

I’ve attached pictures. The stuff in my pool is my coping. I’ve attached what the stone should look like and what it looks like now.

Thanks for your help.

4 months after our pool completion, our limestone started spalling. At that time we had freezing temps, which causes spalling. At this time I had a chlorine puck pool. After about a year I converted to a SWG. It’s gotten worse since the SWG, but I don’t know if that’s the cause.

I did not initially seal the coping, but once is started spalling I sealed it 3 times with stone tech salt water sealant.

The coping is getting worse and worse. I need to replace it.

I’m curious if sealing all sides of limestone before installing would work or if I need a new coping altogether? I’ve read about Oklahoma stone, but it doesn’t fit our pool look.

Please let me know if new limestone sealed would work or if I need new coping, what kind should I install?

I’ve attached pictures. The stuff in my pool is my coping. I’ve attached what the stone should look like and what it looks like now.

Thanks for your help.