- Jun 5, 2019

- 1,657

- Pool Size

- 14000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool Universal40

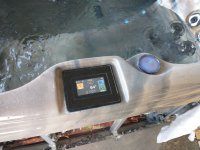

Among three other disasters that happened on a long planned weekend away, my hot tub I think probably has lost it's heating element. (That is most likely but I haven't dug into it yet.) It is popping the GFCI in the Spa Panel.

This was particularly embarrassing as when we were away my across the street neighbor called me because they are buying and adding on a detached hot tub to their pool...and he wanted me to give him recommendations on the wiring job. His house is a mirror image to mine, so he could do exactly what we did (it passed inspection with flying colors). So I looked his stuff over and then I showed him mine.... But when I got to the Spa Panel I noticed that the breaker had popped. I have an external thermometer in there to wirelessly monitor it from the house, and it was only a degree or two down from the set point I put the tub when not in use (91,5F with a 93F set point) so the problem was only a few hours old when the neighbor came over.

Anyway.. it's still a tad bit cold here in Tucson.. probably not enough to worry about, but I don't know if I want to drain the tub yet .... and probably can't work on it for at least two weekends... with a 200+ gallon slug of water there is no way it would freeze, it probably wouldn't even if drained but in that case it probably would be more likely... we are right at the end of the season for that potential... but it's been kinda cold this year here.. so I don't know. I am actually 1000' higher than the fish bowl of Tucson so it does get a little colder at night here.

So should I drain it and try to shop vac it dry or should I try to mix it up once a day and keep the chlorine level up? Luckily it's only 250 gallons, so it's doable... I could drain it down part way, etc. too... I really probably can't seriously fix anything for two weeks at least. (I am actually contemplating calling someone to fix it, because my schedule is so tight now, but I also know I'll get taken if I do...)

I think it's the heating element as it got to the priming screen on the controller and I was able to run the pumps (both) the first time I reset it-- then right afterwards it tripped. I think the controller retains the setting for an hour or two of no power, so subsequent resets trip almost immediately.

Yes, I know it can be a bad GFCI too.. the tub is probably not even three years old, so I am just a little miffed about it, but I would appreciate sage advice from those who have been through this before. It also could be the ozonator, if if so I'll simply disconnect it for good...

The tub was due for a a water change and ahh-some treatment anyway. I hadn't used it in several months because of a medical issue with my left foot but that JUST healed up (but I was keeping the water fairly good despite not changing it... I wouldn't have gotten into it but there wasn't so much neglect that there was something to damage the element), so I was going to get it going again in maybe 2 weekends doing a through cleaning first. The other disasters are worse. I have a transmission problem that happened on Saturday with my daughter's van for example.

The pool has so much dirt and rocks kicked into it from our dogs and a couple of bad wind storms after we "closed it" (you don't here... even the SWCG stays on) that I am contemplating on hiring the spring cleaning of it out too... 2021 was a BAD year for me. Darn near destroyed me. 2022 isn't much better so far.

Never a dull moment in our household, I swear.

Whatever advice you wizards can give me to keep the water from growing Godzilla in the next several days would be appreciated. I do know if it's the GFCI, I can replace that fast and if it's the heater I can probably run the pumps twice daily with it disconnected but it probably will be a couple of evenings before I can diagnose that...

It's a "American Whirlpool" (MAXX) with Balboa innards in it. I guess asking a for a good source of parts now is apropos.

This was particularly embarrassing as when we were away my across the street neighbor called me because they are buying and adding on a detached hot tub to their pool...and he wanted me to give him recommendations on the wiring job. His house is a mirror image to mine, so he could do exactly what we did (it passed inspection with flying colors). So I looked his stuff over and then I showed him mine.... But when I got to the Spa Panel I noticed that the breaker had popped. I have an external thermometer in there to wirelessly monitor it from the house, and it was only a degree or two down from the set point I put the tub when not in use (91,5F with a 93F set point) so the problem was only a few hours old when the neighbor came over.

Anyway.. it's still a tad bit cold here in Tucson.. probably not enough to worry about, but I don't know if I want to drain the tub yet .... and probably can't work on it for at least two weekends... with a 200+ gallon slug of water there is no way it would freeze, it probably wouldn't even if drained but in that case it probably would be more likely... we are right at the end of the season for that potential... but it's been kinda cold this year here.. so I don't know. I am actually 1000' higher than the fish bowl of Tucson so it does get a little colder at night here.

So should I drain it and try to shop vac it dry or should I try to mix it up once a day and keep the chlorine level up? Luckily it's only 250 gallons, so it's doable... I could drain it down part way, etc. too... I really probably can't seriously fix anything for two weeks at least. (I am actually contemplating calling someone to fix it, because my schedule is so tight now, but I also know I'll get taken if I do...)

I think it's the heating element as it got to the priming screen on the controller and I was able to run the pumps (both) the first time I reset it-- then right afterwards it tripped. I think the controller retains the setting for an hour or two of no power, so subsequent resets trip almost immediately.

Yes, I know it can be a bad GFCI too.. the tub is probably not even three years old, so I am just a little miffed about it, but I would appreciate sage advice from those who have been through this before. It also could be the ozonator, if if so I'll simply disconnect it for good...

The tub was due for a a water change and ahh-some treatment anyway. I hadn't used it in several months because of a medical issue with my left foot but that JUST healed up (but I was keeping the water fairly good despite not changing it... I wouldn't have gotten into it but there wasn't so much neglect that there was something to damage the element), so I was going to get it going again in maybe 2 weekends doing a through cleaning first. The other disasters are worse. I have a transmission problem that happened on Saturday with my daughter's van for example.

The pool has so much dirt and rocks kicked into it from our dogs and a couple of bad wind storms after we "closed it" (you don't here... even the SWCG stays on) that I am contemplating on hiring the spring cleaning of it out too... 2021 was a BAD year for me. Darn near destroyed me. 2022 isn't much better so far.

Never a dull moment in our household, I swear.

Whatever advice you wizards can give me to keep the water from growing Godzilla in the next several days would be appreciated. I do know if it's the GFCI, I can replace that fast and if it's the heater I can probably run the pumps twice daily with it disconnected but it probably will be a couple of evenings before I can diagnose that...

It's a "American Whirlpool" (MAXX) with Balboa innards in it. I guess asking a for a good source of parts now is apropos.

Last edited: