Hello All,

First time posting in the forum but I have loved all the info that this community has provided me.

I recently started helping my brother get their inground pool working.

They previously had a 1 HP Sta-Rite Dyna-Glas pump.

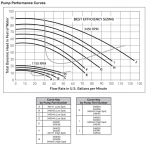

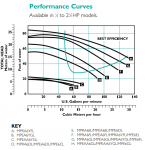

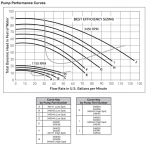

After comparing specs, we decided to replace it with a 1 HP Pentair Superflo since it seemed very similar.

For some reason it still seems like the flow rate is much lower then it should be. One of the skimmers barely seems to pull any debris and the returns just don't feel as strong as they do in my own pool. Unfortunately he does not recall what the performance was with the old pump so I don't have a baseline.. I am suspicious that the old pump was possibly undersized but am trying to confirm.

I tried to calculate the TDH for this setup.

23,000 Gallon inground pool

Piped with 1 1/2", unsure if this is PVC or Flex. The inlet and outlet of the pump are piped to 2".

Equipment List:

48 Sqft DE Filter

Push pull valve

Heater

2 skimmers

1 bottom drain - Skimmers and bottom drain all seem to be piped through same 1.5" line. Pool is too dirty to see if drain is clogged.

3 returns

150 ft pipe (over estimate)

1 Jandy Neverlube valve

4 straight couplings

11 45

13 90

4 Tees

Pump is at the level of the deck, so maybe 2' lift?

The pump primes very quickly and there is no air at all in the basket. The tank pressure with the 1 HP motor is about 18 PSI. This matches the value that the previous owner wrote on the tank.

If i plug these values into the calculator on Pentair's website and used some the values from Swimming Pool Feet of Head Calculations | InTheSwim Pool Blog for the equipment. The calculator says that I will require 78.7 feet of head to achieve a 40 gpm flow. The pressure that they estimate is 34.1 PSI, which seems very high, but I am by no means an expert.

Is anyone able to provide some guidance? Would switching to the 1.5 HP Superflow help fix this problem? Is there actually a problem? It seems that even that pump may be undersized given this setup. Maybe the previous owner added the heater and did not resize the pump? We have been banging our heads against the wall for over a week and just can't figure this out.

First time posting in the forum but I have loved all the info that this community has provided me.

I recently started helping my brother get their inground pool working.

They previously had a 1 HP Sta-Rite Dyna-Glas pump.

After comparing specs, we decided to replace it with a 1 HP Pentair Superflo since it seemed very similar.

For some reason it still seems like the flow rate is much lower then it should be. One of the skimmers barely seems to pull any debris and the returns just don't feel as strong as they do in my own pool. Unfortunately he does not recall what the performance was with the old pump so I don't have a baseline.. I am suspicious that the old pump was possibly undersized but am trying to confirm.

I tried to calculate the TDH for this setup.

23,000 Gallon inground pool

Piped with 1 1/2", unsure if this is PVC or Flex. The inlet and outlet of the pump are piped to 2".

Equipment List:

48 Sqft DE Filter

Push pull valve

Heater

2 skimmers

1 bottom drain - Skimmers and bottom drain all seem to be piped through same 1.5" line. Pool is too dirty to see if drain is clogged.

3 returns

150 ft pipe (over estimate)

1 Jandy Neverlube valve

4 straight couplings

11 45

13 90

4 Tees

Pump is at the level of the deck, so maybe 2' lift?

The pump primes very quickly and there is no air at all in the basket. The tank pressure with the 1 HP motor is about 18 PSI. This matches the value that the previous owner wrote on the tank.

If i plug these values into the calculator on Pentair's website and used some the values from Swimming Pool Feet of Head Calculations | InTheSwim Pool Blog for the equipment. The calculator says that I will require 78.7 feet of head to achieve a 40 gpm flow. The pressure that they estimate is 34.1 PSI, which seems very high, but I am by no means an expert.

Is anyone able to provide some guidance? Would switching to the 1.5 HP Superflow help fix this problem? Is there actually a problem? It seems that even that pump may be undersized given this setup. Maybe the previous owner added the heater and did not resize the pump? We have been banging our heads against the wall for over a week and just can't figure this out.