czb182

Well-known member

Not sure if the issue , but there is some internal adjustment to pressure switch you are supposed to do for Jandy Jxi heater if equipment more than one foot above pool

The pressure switches can sometimes be adjusted, but you need to be very careful about adjusting the switch.Not sure if the issue , but there is some internal adjustment to pressure switch you are supposed to do for Jandy Jxi heater if equipment more than one foot above pool

The pressure switch is preset at the factory for most typical, deck level installations.

When the heater is located above or below the level of the pool or spa, the pressure switch may require adjustment to compensate for the change in static head pressure.

The following procedure is recommended when the switch needs adjustment and/or is replaced:

For Installations with Heater Above Water Level:

1. Be sure the filter is clean before making the adjustment.

2. Turn “ON” the filter pump and ensure all air is out of the water lines, and ensure water flow rate is at least the rated minimum (see Figure 10).

3. Turn “ON” the heater and adjust the thermostat to create a call for heat.

4. If the heater does not light, adjust the pressure switch by turning the adjustment knob on the pressure switch counter-clockwise, until the heater lights.

Turning the adjustment knob counterclockwise decreases the pressure needed to close the switch.

5. Check the function of the pressure switch by turning the filter pump on and off several times.

The pool heater should turn off immediately when the pump is turned off. Never allow the heater to operate with less than the minimum rated water flow rate.

For Installations with Heater Below Water Level:

1. Be sure the filter is clean before making the adjustment.

2. Turn “ON” the filter pump and ensure all air is out of the water lines, and ensure water flow rate is at least the rated minimum (see Figure 10).

3. Turn “ON” the heater and adjust the thermostat to create a call for heat.

4. Turn the adjustment knob on the pressure switch clockwise, until the heater turns off, then turn the knob ¼ turn counter-clockwise, so that the heater turns back on.

Turning the adjustment knob clockwise increases the pressure needed to close the switch.

5. Check the function of the pressure switch by turning the filter pump on and off several times.

The pool heater should turn off immediately when the pump is turned off.

Never allow the heater to operate with less than the minimum rated water flow rate.

The flow switch need to be set to trigger at about 10 gpm per 100,000 btu/hr of heater.

A 200,000 btu/hr needs 20 gpm.

a 400,000 btu/hr heater needs 40 gpm etc.

Contact Harwil for the right flow switch that will fit in the 2" T with a 1/2" female thread.

The Aquarite SWG flow switch triggers at about 15 to 20 gpm, so it won't be a good choice for a bigger heater like a 400,000 btu/hr.

What is the filter pressure at full speed?

Is the pump wired to 115 or 230 volts?

If you can get a vacuum reading that would be helpful.

If you added a flow meter, that would help diagnose the issue.

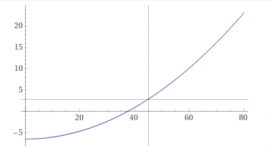

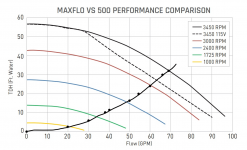

If you can convert the filter pressure and vacuum pressure to feet of head, you can see what the expected flow rate is supposed to be at the below speeds.

For example, if the vacuum plus filter pressure is 20 psi, the total head is about 46.2 feet.

If we look at 46.2 feet of head and 115 volts, the flow is expected to be about 37 gpm.

If the pump is receiving 115 volts, the top speed is reduced to limit the maximum amps as shown in the black dotted line.

How far is the pump from the pool?

View attachment 337547

The flow before and after the heater have to be the same.Am I correct in assuming that the flow rate before and after the filter would be virtually the same, especially at lower speeds?

which is spot on for 3 turnovers a day.

I find myself having to run the pump at 90% or more to keep the heater flow sensor happy.

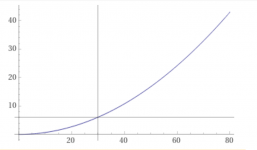

90% is 3,100 rpm.When the filter (DE4820) gets even a bit dirty, even 100% pump speed may not be enough to maintain the minimum flow rate for heating.

2,400 rpm crosses the system curve at about 48 gpm.2400RPM (40GPM) seems to keep the pressure switch happy.

90% was needed before I adjusted the pressure switch. 70% does the trick now, but I had to adjust the switch to its minimum limit.90% is 3,100 rpm.

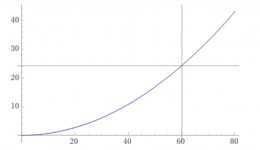

The pressure switch might be 2 or 3 psi from the factory.

My estimate is for 4 psi to keep the pressure switch securely closed and not chattering.

You might be able to get down to 2 or 3 psi.

If you adjust it down to 1 psi, you can make it work with lower flow, but you have to be careful not to make the heater run with no flow.

With a flow switch, the system can run at 25 to 30 gpm, which should be good for heating and efficiency.