Pump Stops After An Hour Or So..........

- Thread starter IguanaSwim

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

120 or 240 volts?

How far is the pump from the electrical panel?

What's the amperage of the circuit breaker?

What gauge wire from pump to circuit breaker?

Do you know how to measure voltage drop?

How far is the pump from the electrical panel?

What's the amperage of the circuit breaker?

What gauge wire from pump to circuit breaker?

Do you know how to measure voltage drop?

Auburn02

Well-known member

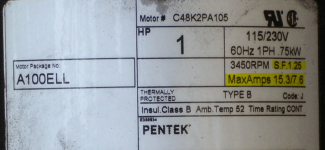

Sounds like you are getting 120V to the pump so that's good if it is indeed designed to operate that way. That would be my first question. Was that motor configured for 120 or 240 from the factory?

Yeah, I'm definitely not an expert but earlier 120V was verified at the pump, but this photo of the label on the pump clearly says "Motor prewired 230 volt" - so could the 120 voltage at the pump be the problem?120 or 240 volts?

- Jun 22, 2014

- 52,167

- Pool Size

- 17888

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

Certainly. To be getting 120V at the pump (from the source), your 220V motor is stared for voltage.so could the 120 voltage at the pump be (part of) the problem?

Last edited:

Auburn02

Well-known member

I thought it was tested at both, but not sure if it was under load. I know nothing about those dials and such though, but I do see the 115 indicator your arrow is pointing to.Looks like the dial is set to 115 volts.

The voltage was verified at the timer, not the pump.

The voltage needs to be verified at the pump terminals under load.

The amperage also needs to be checked, which should be relatively easy with the big loops of wire available.

View attachment 363752

ferretbone

In The Industry

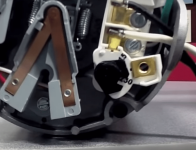

I can tell from the first pic it's 1. over heating, your sticker is peeling of from a hot motor. It's shutting off and cooling down and running again right? If so replace the motor it's toast.I replaced the impeller and the problem is still there. Pump ran for 35 minutes and shut off. I should have taken the temp of the casing but did not do that. At this point, the people at the plumping place where I bought this suspect some sort of wiring issue.

I have checked continuity of the three wires running between the timer and the motor.

For the White and Black wires, the continuity was at mostly .8 or .7 and jumped around somewhat between 9 thru 6. The beeping noise was not constant, but irregular. For example, a 3 second beep and then a few 1 second beeps, and then another 3 second beep.

For the Green wire, I got a continuous beep and many different numbers flashing on my MM. 26.5, 1.5. etc., etc. I don't think it ever flashed OL. Is the green wire broken inside the conduit?

I can understand the view of the pool pump store, they don't want to exchange a pump if the motor was damaged by faulty wiring.

check the timer for 120, then the back of the motor for 120. If the timer is giving 120 but your not getting it at the motor, it's the whip. If your getting 120 at the timer, and motor, then the motor is toast. If it's over heating from leaves and what not blocking the sides and under the motor, clear it all out if it stops giving you problems fine but you've shorted the life of the motor.

If you impeller was to big and you've changed to the right size it will quit over heating and you will have again shorted the life of the motor.

Also I can't tell if your selector is switched on the motor to 120 or 240. The black knob on the lower right. should be turned all the way to the left if it can be wired both 240 or 120.

NowintersinAZ

Well-known member

- Oct 18, 2020

- 188

- Pool Size

- 7560

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- Intex Krystal Clear

The noise you heard when you first installed the motor could have been a bearing. That's a speculation.

Your voltages are fine It would appear the replacement pump is to small for your system and has been overheating and going out on thermal overloads.

I would replace the pump with the one recommended for your system as this one now has been abused and is slowly burning up. Replace the broken warn our parts in the impeller with like parts you have now and enjoy your pool.

Your voltages are fine It would appear the replacement pump is to small for your system and has been overheating and going out on thermal overloads.

I would replace the pump with the one recommended for your system as this one now has been abused and is slowly burning up. Replace the broken warn our parts in the impeller with like parts you have now and enjoy your pool.

NowintersinAZ

Well-known member

- Oct 18, 2020

- 188

- Pool Size

- 7560

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- Intex Krystal Clear

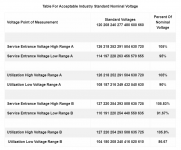

The goal of the power company is to supply you with 120/240 but the code allows a 5% volt drop from service drop to the furthest run on the property.How do you know his voltage is fine?

He was 123 volts at the timer that's excellent. He has 118 volts at the pump, that's a 4% volt drop. Also the pump is rated at 115 volts to accommodate for volt drop. So this motor is safe to run at 115 volts IF that is what was available.

He has 118 volts so for the motor his voltages are fine.

The OP does not say that they measured the voltage at the pump under load.

The OP needs to measure the voltage at the pump under load and the amperage.

They need to say what new impeller was installed.

They should also check to see if the pump shaft turns freely or if it feels like it is binding.

The OP needs to measure the voltage at the pump under load and the amperage.

They need to say what new impeller was installed.

They should also check to see if the pump shaft turns freely or if it feels like it is binding.

NowintersinAZ

Well-known member

- Oct 18, 2020

- 188

- Pool Size

- 7560

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- Intex Krystal Clear

If the pump which it sounds like is over working the readings will be skewed.The OP does not say that they measured the voltage at the pump under load.

This will also be skewed and a useless reading.The OP needs to measure the voltage at the pump under load and the amperage.

He did pull the impeller and showed close ups of it. Not sure if the numbers show the size.They need to say what new impeller was installed.

Seeing if the pump spins freely is no longer something that matters as the pump is known to be to small, overheating and going out on internal thermal overloads, and needs replacing with the motor that the system requires.They should also check to see if the pump shaft turns freely or if it feels like it is binding.

His Whisper Flo requires a 1 1/2 HP motor with a service factor of 1.10.

He installed a 1 HP with a service factor of 1.25 the pump was doomed from the get go.

I replaced the impeller and the problem is still there.

The voltage and current under load are important and useful.This will also be skewed and a useless reading.

If the current is higher than 15.3 amps, then the motor is overloaded or it is failing.

The voltage should not be dropping significantly out of range unless there is a problem.

They say that they replaced the impeller, but they do not say what impeller they used.He did pull the impeller and showed close ups of it.

Based on the current motor total hp of 1.25 hp, a 073126 or a 073127 impeller would be acceptable and a bigger impeller would be too big.

If the shaft is not turning freely, then it will cause the motor to be overloaded even if the impeller is the correct size.Seeing if the pump spins freely is no longer something that matters as the pump is known to be to small

Making sure that the shaft is not obstructed or binding is always relevant.

NowintersinAZ

Well-known member

- Oct 18, 2020

- 188

- Pool Size

- 7560

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- Intex Krystal Clear

The motor is bad do to overloading and being to small, any reading under load will erroneous do to motor failure.The voltage and current under load are important and useful.

See above remarkIf the current is higher than 15.3 amps, then the motor is overloaded or it is failing.

What significant? What is out of range?The voltage should not be dropping significantly out of range unless there is a problem.

We already know there is a problem hence the OPs post and information.

It would only be relevant if it was the only reason the motor was going out on overloads. It is not the only variable there are at least two other factors and now the pump is bad because it's been over heating and needs replacing. So if the pump does not spin freely is of no concern as it needs replacing anyway.If the shaft is not turning freely, then it will cause the motor to be overloaded even if the impeller is the correct size.

Making sure that the shaft is not obstructed or binding is always relevant.

The motor might be damaged, but we do not know that for sure.The motor is bad do to overloading and being to small,

We need to know what new impeller was installed to make sure that it is not the cause of the overheating.

We need to know that the shaft turns freely.

We need to know that the voltage is in range.

If the voltage is dropping below 108 volts under load, then there is a problem that needs to be addressed.

If we can verify that one or more of these three things are not the cause of the motor shutting down, then we can probably conclude that the motor is indeed bad.

Last edited:

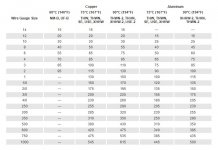

Knowing the gauge & length (run) of the wire would help determine if voltage drop is a problem. Although that wouldn't rule out a bad connection somewhere.

Nowinters - good point about a bad motor causing excessive voltage drop but what if the voltage is good under load? Wouldn't that be nice to know? My concern is burning up another replacement motor if the wiring has a problem.

It would also be nice to know how long the original motor lasted.

Hopefully the OP will respond in the next few days.

Nowinters - good point about a bad motor causing excessive voltage drop but what if the voltage is good under load? Wouldn't that be nice to know? My concern is burning up another replacement motor if the wiring has a problem.

It would also be nice to know how long the original motor lasted.

Hopefully the OP will respond in the next few days.

The voltage drop depends on the current.good point about a bad motor causing excessive voltage drop but what if the voltage is good under load?

If the current was high enough to drop the voltage below 108 volts, the breaker would probably trip.

If the OP has a 20 amp circuit breaker it must trip at a sustained current of 27 amperes (135 percent) at less than one hour, and at 40 amperes (200 percent of wire rating) in less than 120 seconds.

These two trip points (135 percent and 200 percent) are defined in NEMA Standard AB-1, MCCBs and Molded Case Switches.

Assuming they have 100 feet of #12 wire from the circuit breaker to the pump, the current would need to be about 30 amps to drop the voltage from 120 volts to 108 volts.

That should be tripping the circuit breaker if that was the case.

Even if the current is that high, we do not know for sure that it is due to a bad motor.

An oversized impeller and/or a binding shaft will cause excessive current.

If the current is not higher than 15.3 amps and the voltage is dropping below 108 volts, then there is a power supply problem.

Last edited:

NowintersinAZ

Well-known member

- Oct 18, 2020

- 188

- Pool Size

- 7560

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- Intex Krystal Clear

I have been saying the pump is bad. When I say this whether the pump is damaged or not it's not the right pump.

Hence the pump is bad. Sorry for not being clear on that.

On the fact alone that the pump falls a 1/2 HP short of the nameplate of the Whisper Flo it needs replacing with the correct motor.

I would call and see if it could be swapped out with the correct motor under warranty.

Then all other tests will hold water as long as the new motor is good.

Hence the pump is bad. Sorry for not being clear on that.

On the fact alone that the pump falls a 1/2 HP short of the nameplate of the Whisper Flo it needs replacing with the correct motor.

I would call and see if it could be swapped out with the correct motor under warranty.

Then all other tests will hold water as long as the new motor is good.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.