Hello,

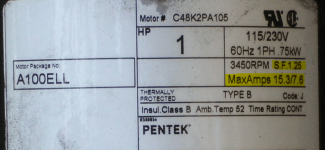

This pump A100ELL is less than a year old, so it is still under warranty. When I installed it last December I heard a faint high pitched tone and I nearly took it back. In fact, I called the place where I bought it and they encouraged me to return it. But one thing led to another and I kind of got used to the extra little noise so I never took it back.

Now the pump is stopping each time I turn it on. It runs for a little over an hour and then shuts itself off. The repairman at the place where I bought it wanted me to check the voltages to be sure good electricity is getting to the pump before I take it to the repair shop. I've just finished researching that and want to verify.

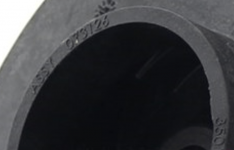

That black wire might look like it's cut off, but it actually attaches to the screw about an inch before the end of the wire.

The multi meter said that there was 118 volts when I put the black probe on the black line and the red on the white wire. The multimeter said 118 when I put the black probe on the green screw and the red probe on the black line. When I tried the same with the green and the white I got zeros.

I also checked the timer box.

Here I got 123 volts between the left and middle screws, and the middle and the right ones. When I tried the left and the right connections I got zeros.

It looks to me like the electricity going to the motor is good, but I wanted to post and verify.

Thumbs up?

This pump A100ELL is less than a year old, so it is still under warranty. When I installed it last December I heard a faint high pitched tone and I nearly took it back. In fact, I called the place where I bought it and they encouraged me to return it. But one thing led to another and I kind of got used to the extra little noise so I never took it back.

Now the pump is stopping each time I turn it on. It runs for a little over an hour and then shuts itself off. The repairman at the place where I bought it wanted me to check the voltages to be sure good electricity is getting to the pump before I take it to the repair shop. I've just finished researching that and want to verify.

That black wire might look like it's cut off, but it actually attaches to the screw about an inch before the end of the wire.

The multi meter said that there was 118 volts when I put the black probe on the black line and the red on the white wire. The multimeter said 118 when I put the black probe on the green screw and the red probe on the black line. When I tried the same with the green and the white I got zeros.

I also checked the timer box.

Here I got 123 volts between the left and middle screws, and the middle and the right ones. When I tried the left and the right connections I got zeros.

It looks to me like the electricity going to the motor is good, but I wanted to post and verify.

Thumbs up?