Yes, Marty is on it. Might have been who taught that to me. While the

speed of the water might vary based on what it is passing through at any given point (a pipe compared to, say, a filter, or a valve body), the

flow (the volume of water) is exactly the same from one end of your system to the other.* Riny is on it, too. You only need one Vis, put it where it is always "in the loop" and/or where it is easiest to read. There is a knack to reading a FlowVis, you have to align your line of sight just so, so you have to have good access to the lens, directly in front of it, to get a good reading.

I didn't know they had a digital one. While it might be cool to get flow rate readings remotely, they really don't change all that much. You should be checking your pad once a day anyway (for leaks and pressures and flow, etc). If anything, a digital solution will just make you lazier about paying attention to your pool, instead of your screens. Not to mention: digital = one more thing to poop out.

Regarding your "bottleneck" experiment: you can still perform that, if you care to. Put the Vis in one of the check valve bodies, observe it for a period of time. Then physically move it to the other check valve body, lather, rinse, repeat. You don't need two Vis to do that. And since they're both going to be reading exactly the same anyway, you'd only be kicking yourself that you bought two!

* Technically, you

can wind up with different flow rates within a single system, if within that system you have some sort of bypass path. If the flow is split somewhere into two paths, each path could have a different flow rate, and each of those would be different from elsewhere in the system. But right after the two paths merged back together, the rate of flow at that point would be identical to the rate of flow right before they split. Similarly, if you have a return manifold that splits your filtered water into two or more pipes, each of those pipes could have different flow rates, and each of those would have a lower flow rate than the main filter circuit. But for the purpose of your solar system, the flow rate in the pipes to the roof, or just before the filter, or between the filter and solar valve, or right after the heater, etc, all those flow rates will be the same.

They want $123 for just the guts? Yikes. Well, welcome to the supply chain, I guess... But that's the exact part I was referring to. And it looks like it'll go right into either of your Jandy housings.

If you're moving ahead with the Vis, then all the other discussions about bubbles and pipe temperatures, etc are moot.

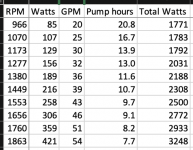

I do want to point out BMerrill's post, where he was kind enough to build you a nice chart of flow rates. But he actually has reinforced a point I made earlier. You can't use his chart for anything but comparison, certainly not for setting up your system. I get 40 GPM at 2200 RPM. Apparently, that would only need about 1100 RPM in BMerrill's pool! That's a

100% difference (and that's just the RPM, cost would be even father "off the chart.") Plus, he doesn't have panels, which affects the flow rate drastically. That really illustrates why guessing and feeling and bubbles and "rule of thumb" or whatever are just not going to hold up to all the variables involved. If you really want to optimize flow through your panels, ya kinda need something that specifically measures flow, and measures that flow in

your pool...