Not at all. At least not my perception. Your answers are spot on.it was generally thought that we were just trying to pad the bill, as seems to be the consensus here.

Preventive maintenance for Intelliflo pump?

- Thread starter Rocket J Squirrel

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

If they would just use the best seals and bearings from the beginning, it wouldn't be an issue.

Bearings make no sense to replace unless they are obviously bad and even then, it's rarely worthwhile.

A service person is going to have 4 to 5 hours in replacing bearings by the time you consider drive time, disassembly of the pump and motor, finding the right parts, shop time, reassembly etc.

At $150.00 per hour, that's $750.00 in charges just for labor.

Bearings make no sense to replace unless they are obviously bad and even then, it's rarely worthwhile.

A service person is going to have 4 to 5 hours in replacing bearings by the time you consider drive time, disassembly of the pump and motor, finding the right parts, shop time, reassembly etc.

At $150.00 per hour, that's $750.00 in charges just for labor.

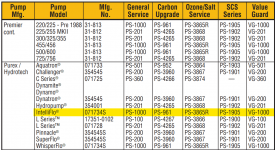

The PS-1000 is a lower quality seal in my opinion.Us Seal PS-1000 seal, $10.00 on Amazon. (Pentair just repackages them and raises the price). Or get the whole generic kit (seal, gasket, O rings) there for about $20.00. The generic stuff lasts just as long as OEM

The minimum anyone should use is the "Ozone/Salt" rated seal and the silicon carbide is the best.

In my opinion, the manufacturer should use silicon carbide.

IntelliFlo® VSF Variable Speed and Flow Pool Pump

The IntelliFlo VSF pump is the first of its kind to respond to changes in your pool’s environment in order to maintain a preprogrammed flow rate. There’s no more guesswork—just set the desired flow rate and the pump will adjust as needed. It’s like cruise control for your pump. And, the...

Last edited by a moderator:

Rocket is there a full service pool store you could take it to nearby ? Dropping it off would save the need to recoup labor charges for the drive time and estimate.

You have alot to digest here, all of it great stuff, from both sides. Keep us posted.

You have alot to digest here, all of it great stuff, from both sides. Keep us posted.

I would love to have worked in your area if those are the prices service techs get. Usual cost for the job, if the bearings need replacing - $250 -$300 or so, motor shops have raised their prices, so not sure now. And, at least locally, they charge more for a VSP motor. That's if the motor is repairable. Generally the through bolts that hold the assembly together will break off in the front end bell if the seal had been leaking for a long while. For a pool motor, it was never worth the cost to have a motor shop replace the end bell or drill and machine it to replace those bolts. A motor can be used if only two, on the diagonal, are missing. VSP motors are worth the cost.If they would just use the best seals and bearings from the beginning, it wouldn't be an issue.

Bearings make no sense to replace unless they are obviously bad and even then, it's rarely worthwhile.

A service person is going to have 4 to 5 hours in replacing bearings by the time you consider drive time, disassembly of the pump and motor, finding the right parts, shop time, reassembly etc.

At $150.00 per hour, that's $750.00 in charges just for labor.

The actual process, unless the service person has the tools and time to do the job, or works for a very large service company, is remove the motor, take it to a reliable motor shop for the bearings on your way to a supplier or the next job, return a day or so later on your way to another job, reinstall with a new seal, gaskets, etc. in about half an hour, get paid, go on. Generally, if one is any any good, we don't have time to repair a motor. Its not that hard, I used to do it in the off season, but not that profitable either for the time it takes. We let the pros do it.

That's one reason for the recommendation to replace the seal ever 5 years, to save the bearings. Always thought that bearing replacement at that interval was overkill, just passing along what the manufacturers said. Also said that neither is done except for the very unusual pool owner with pool equipment still lasting a long time. OP asked what would be recommended for a 10-year old pump to increase its life span. Similar to, " I'm taking a long car trip in my 10-year old vehicle, what do you recommend so there are no problems along the way?"

Not sure on what you base the statement the PS-1000 is junk, they have proved reliable for years. Are viton, silicon carbide, etc. better materials? Yes. Do they last longer in the real world where people let their pumps run dry, their pump and skimmer baskets sit clogged for days or weeks so no water flows, their tab feeder allowed to sit idle and a very corrosive "soup" flow back into the system? Not really.

Not sure how one would quantify "the best" seal and bearings. Seals and bearings are "wear" items. They move and rub one part against another, therefore they wear out even without outside influence, like a pump running dry, or a seal leaking and washing the lubrication out of a bearing.

It uses a plastic primary ring, which is the part that rubs on the ceramic.Not sure on what you base the statement the PS-1000 is junk

This wears out fast especially if it runs dry.

The Ozon/Salt rated seal has a carbon primary ring, which is a lot stronger and longer lasting and more heat resistant and a polished ceramic seat.

Not really.they have proved reliable for years.

They fail on a regular basis which is why the recommendation for routine maintenance.

Most service people vastly underestimate their total labor cost in man-hours for most jobs.

First, you have a CSR (Customer Service Representative) answer the phone, take the call and write up a service ticket, which might take 10 to 15 minutes depending on if it is an existing customer or a new customer.

Then, the service manager has to work the job into the schedule.

Someone has to find and/order any parts necessary.

Maybe you have to go to the wholesale place to pick up parts and that takes time.

The service technician and a helper (two people, so labor times 2) have to drive to the job, arrive, talk to the customer for 10 to 15 minutes, shut down the system, take the pump apart, secure the electrical and plumbing, write up the job details, drive to the motor shop, drive back to the shop etc.

Then, drive back to the motor shop when the motor is ready, pick it up and then drive to the job and reinstall everything.

Then, they have to write up the ticket and try to get paid.

All in, you're lucky if your man-hours are below 5 hours total.

Maybe you charge $100.00 or $200.00, which is $20.00 to $40.00 per hour, which means that you're realistically losing money.

Most services either lose money or barely break even because they don't know their real job costs and they don't charge full value.

First, you have a CSR (Customer Service Representative) answer the phone, take the call and write up a service ticket, which might take 10 to 15 minutes depending on if it is an existing customer or a new customer.

Then, the service manager has to work the job into the schedule.

Someone has to find and/order any parts necessary.

Maybe you have to go to the wholesale place to pick up parts and that takes time.

The service technician and a helper (two people, so labor times 2) have to drive to the job, arrive, talk to the customer for 10 to 15 minutes, shut down the system, take the pump apart, secure the electrical and plumbing, write up the job details, drive to the motor shop, drive back to the shop etc.

Then, drive back to the motor shop when the motor is ready, pick it up and then drive to the job and reinstall everything.

Then, they have to write up the ticket and try to get paid.

All in, you're lucky if your man-hours are below 5 hours total.

Maybe you charge $100.00 or $200.00, which is $20.00 to $40.00 per hour, which means that you're realistically losing money.

Most services either lose money or barely break even because they don't know their real job costs and they don't charge full value.

My Polaris PB4-60 was rebuilt about 8 years ago with a PS-1000. No leaks. I rebuilt my neighbor's ancient Whisperflo (original Purex), took it from a 1.5hp to a .5hp, about 15 years ago. PS-1000 seal. Still running with no leaks. I was just over there last week to replace a 25 year-old Intermatic T104M and checked the whole system for him.It uses a plastic primary ring, which is the part that rubs on the ceramic.

This wears out fast especially if it runs dry.

The Ozon/Salt rated seal has a carbon primary ring, which is a lot stronger and longer lasting and more heat resistant and a polished ceramic seat.

View attachment 455829

Not really.

They fail on a regular basis which is why the recommendation for routine maintenance.

If the pool is salt, or a commercial pool, I will use a Viton like the 3960 and let the owner know, just so they feel better. I have yet to see one actually last that much longer in use. Its listed as "More forgiving when the pump is run dry of accidentally loses prime."

This is just my experience and been my successful practice. It is what I base my recommendations on. Anything beyond that is what the manufacturers have said.

You're making the very erroneous assumption that I can't arrange my schedule to be time effective. So, based on that, I've been losing money for the past 33 years and am actually living in a deficit situation, though I am completely debt free.Most service people vastly underestimate their total labor cost in man-hours for most jobs.

First, you have a CSR (Customer Service Representative) answer the phone, take the call and write up a service ticket, which might take 10 to 15 minutes depending on if it is an existing customer or a new customer.

Then, the service manager has to work the job into the schedule.

Someone has to find and/order any parts necessary.

Maybe you have to go to the wholesale place to pick up parts and that takes time.

The service technician and a helper (two people, so labor times 2) have to drive to the job, arrive, talk to the customer for 10 to 15 minutes, shut down the system, take the pump apart, secure the electrical and plumbing, write up the job details, drive to the motor shop, drive back to the shop etc.

Then, drive back to the motor shop when the motor is ready, pick it up and then drive to the job and reinstall everything.

Then, they have to write up the ticket and try to get paid.

All in, you're lucky if your man-hours are below 5 hours total.

Maybe you charge $100.00 or $200.00, which is $20.00 to $40.00 per hour, which means that you're realistically losing money.

Most services either lose money or barely break even because they don't know their real job costs and they don't charge full value.

Being the whole company, I answer the phone, schedule the call, arrange the route I drive to take advantage of where I will be during the day, so that I will literally be close to a shop (I have used three in my area depending on where the job is located, all good shops), do the billing, take vacations and holidays if I feel like it. And if a job is not to my liking, I will refer it to another company or just say no. Unlike many in the position you describe, because I price right, I can be selective.

Not sure why in the world it would take 2 people to do so simple a job as a motor repair. Even at my age (which is old) I've installed two heaters and two new motors in the last month, all alone. Yes, I've slowed down considerably. Used to do one or two heaters a day, if not for me for other companies. I used to be big and strong, now just big and old but still "kicking."

If I should need parts at a supplier, I use this amazing thing we all have, call ahead (on bluetooth) and order them. There is hardly a job out there that I can't recall from memory what is needed to get the job done. In and out quickly, usually picking up parts for several (or a couple now) jobs at once, saves time. I also seldom need to go to a job for an estimate on the repair, just like the advice given here, don't need to be there. I know what the jobs take to get done. No extra trips or added cost. Nothing special about that, just done it hundreds of times.

Despite your assertation to the contrary, I really do know how to run a successful business and set my prices, and, to the disdain of many, make a reasonable profit. Maybe you've been in a service business and your experience is different, but please don't tell me mine doesn't work

I have a local Leslie's. I don't know whether they have anyone competent who works on pumps.Rocket is there a full service pool store you could take it to nearby ? Dropping it off would save the need to recoup labor charges for the drive time and estimate.

You have alot to digest here, all of it great stuff, from both sides. Keep us posted.

Given the choice between doing something and doing nothing, nothing is easier. The rebuild process looks risky because there are so many steps to potentially screw up.

My pump is so happy & healthy I'll probably wait until it makes a noise or springs a leak. I had it open this week for regular maintenance and it's in such good shape I don't want to mess with it, even knowing about the wear items. When they wear out, they'll wear out. Thanks to the contributors to this thread, I have gained knowledge.

Turbo1Ton

Gold Supporter

- Dec 26, 2019

- 1,995

- Pool Size

- 14500

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

For what it's worth, I had a seal go bad on my primary pump this spring. I ordered the US Seal PN James linked above for the ozone/salt service, and a generic seal kit that also contained the PS-1000 seal. I am a mechanically inclined DIY'er, so I wasn't concerned with my abilities. I was however somewhat concerned with the procedure, simply because I remembered from my days as a pump engineer, that the shaft seals were the most delicate part of the whole operation.

I completed the job in about 1 hour, with the help of the video posted previously. Not difficult at all.

I would likely buy the parts to have on hand, and wait for the seal to fail, before I changed it, that way you aren't down for any length of time while waiting on parts. Mine was a slow leak, and I have a water features pump that I can easily swap over to filter duty if needed. So I wasn't worried about being down.

--Jeff

I completed the job in about 1 hour, with the help of the video posted previously. Not difficult at all.

I would likely buy the parts to have on hand, and wait for the seal to fail, before I changed it, that way you aren't down for any length of time while waiting on parts. Mine was a slow leak, and I have a water features pump that I can easily swap over to filter duty if needed. So I wasn't worried about being down.

--Jeff

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.