Given the same pool and equipment setup I could choose different horse power variable speed pumps from the same brand such as the Hayward 1.85 or 2.7 HP Tristar. Is there any operating cost downside to the 2.7 HP pump?

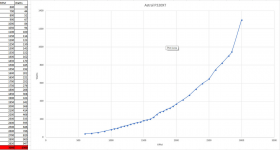

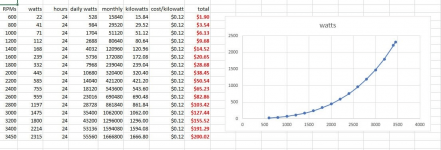

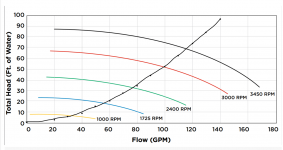

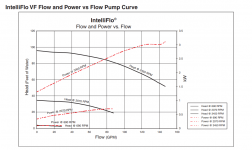

I guess (based on the published performance curves) the higher HP pump (in the same line) must have a different impeller because it pushes more water at the same RPM, and therefore it must be using more watts. So, I could run the higher HP pump at a bit lower RPM. But, looking at the performance curves of the different pumps the gallons moved at a given RPM and speed don't differ by as much as the rated HP differs, so I'm not sure what that means about the power used per gallon pumped.

I guess (based on the published performance curves) the higher HP pump (in the same line) must have a different impeller because it pushes more water at the same RPM, and therefore it must be using more watts. So, I could run the higher HP pump at a bit lower RPM. But, looking at the performance curves of the different pumps the gallons moved at a given RPM and speed don't differ by as much as the rated HP differs, so I'm not sure what that means about the power used per gallon pumped.

Last edited: