So, I finally got the meter and took some current measurements (

see attached pics). The results were as follows:

- Main pump: 9.88 Amps → 2.17 kWh

- Vacuum pump: 6.88 Amps → 1.5 kWh

Recap of My Original Calculations Based on the Electric Company’s Usage Chart:

- Baseline: ~0.07 kWh

- Main pump: (0.64 - 0.07) kWh × 4 → 0.57 kWh × 4 = 2.28 kWh

- Vacuum pump: (2.12 - 0.64) kWh × 4 → 1.48 kWh × 4 = 5.92 kWh

While I was pretty close on the

main pump (2.17 kWh actual vs. 2.28 kWh calculated), I was

way off on the vacuum pump (1.5 kWh actual vs. 5.92 kWh calculated). I'm chalking this up to the

run time being too short (less than an hour) and the

possibility of another device running—someone mentioned a space heater, which could explain the discrepancy.

That said, I’m confident in the calculations from before I moved in:

- Baseline (no pump running): ~0.04 × 4 → 0.16 kWh

- Main pump: (0.57 - 0.04) kWh × 4 → 0.53 kWh × 4 = 2.12 kWh

- Vacuum pump: (0.90 - 0.57) kWh × 4 → 0.33 kWh × 4 = 1.32 kWh

Someone in the thread mentioned that

if the pump lines were clogged, the pump would actually draw less current. This seemed counterintuitive to me since I imagined a

vacuum cleaner struggling when clogged, but I guess that shows how much I know about pumps. This could explain why

the vacuum pump usage increased from 1.32 kWh before I moved in to 1.5 kWh afterward. When I first moved in, the pool

hadn't been maintained for almost two months, so it was full of leaves, and the Polaris bag was also packed with them. I assume this

reduced flow enough to lower the current draw by about 10%.

To verify my findings, I plan to

run the vacuum for 4 hours while ensuring

nothing else is running in the house. This should help confirm whether the

electric company’s usage chart aligns with my actual calculations - which it really should.

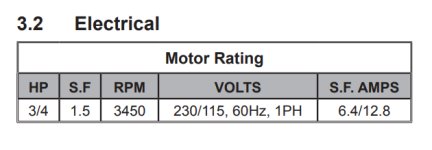

I guess my only question at this point is if these

measured usage values seem correct? The vacuum pump seems to

draw a lot of power compared to the main pump, is that expected for this particular model?

- 2.17 kWh for a 2HP Century B130 pump

- 1.5 kWh for a PB4-60 pump