Hello everyone!

I could really use some help diagnosing possible causes of low flow/gpm in our system.

We moved into this house in early 2021. The pool is somewhere in the neighborhood of 15-18 years old and is probably ~20,000 gallons based on my very rough calculation (including the built-in spa with spillway).

Whenever the pump runs, the spa spillway creates a nice water feature effect which we really like. We live in San Diego and have the doors open to the backyard much of the year, so I wanted to basically have the pump & spillway running from 7a-11p every day (killing 2 birds - for both ambiance as well as cleaning/filtration). As a result, I thought it would be wise to replace the aging single speed pump with a variable speed pump, figuring it would pay for itself quickly - especially since our electric rates are insane (we pay an average total blended rate of ~0.40/kWh).

Upon moving into the house, we retained the pool guy that's been working on this pool for many years and he swapped out the pump with a Pentair IntelliFlo VSF and installed a Pentair SWCG last Spring/Summer.

The ScreenLogic app displays the approximate GPM for any given speed. My understanding from reading some threads here is that this is a calculated/approximate value based on the wattage being used by the pump, etc.

Our GPM numbers with the VSF pump seem a bit lower vs. what many others have posted here after searching through some past threads. The filter was cleaned 3 months ago (the pool guy cleans it twice per year).

For example:

The SWCG needs a minimum GPM (~25 GPM), as does the Hayward suction cleaner in order to be effective (~30+ GPM), as does the Pentair MasterTemp 400 heater (40 GPM minimum according to the manual). I also like to achieve 1 turnover per day (I realize many here say this is not necessary, but 1 turnover a day is basically a given anyway if I run the pump for 16 hours a day for the spillway water feature ambiance effect).

Ideally, I’d love to boost the GPM flow rate so that I can run the pump at lower RPMs and use less electricity. What could be holding us back? Are there issues you see with the way the system is plumbed that could be causing issues? Are the valves set correctly? I'm a bit of a novice at anything equipment-related. Pics attached.

Appreciate any assistance you can offer if there’s something you think we could change that might make a significant difference or more troubleshooting steps you think I should take.

Thanks!

I could really use some help diagnosing possible causes of low flow/gpm in our system.

We moved into this house in early 2021. The pool is somewhere in the neighborhood of 15-18 years old and is probably ~20,000 gallons based on my very rough calculation (including the built-in spa with spillway).

Whenever the pump runs, the spa spillway creates a nice water feature effect which we really like. We live in San Diego and have the doors open to the backyard much of the year, so I wanted to basically have the pump & spillway running from 7a-11p every day (killing 2 birds - for both ambiance as well as cleaning/filtration). As a result, I thought it would be wise to replace the aging single speed pump with a variable speed pump, figuring it would pay for itself quickly - especially since our electric rates are insane (we pay an average total blended rate of ~0.40/kWh).

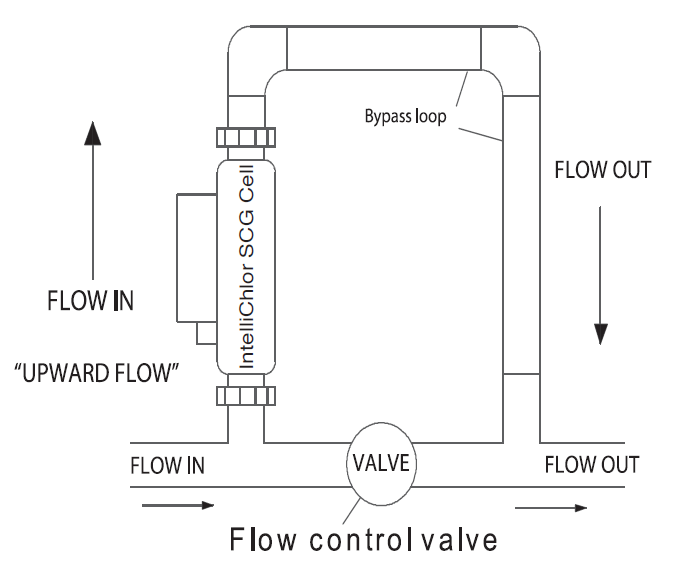

Upon moving into the house, we retained the pool guy that's been working on this pool for many years and he swapped out the pump with a Pentair IntelliFlo VSF and installed a Pentair SWCG last Spring/Summer.

The ScreenLogic app displays the approximate GPM for any given speed. My understanding from reading some threads here is that this is a calculated/approximate value based on the wattage being used by the pump, etc.

Our GPM numbers with the VSF pump seem a bit lower vs. what many others have posted here after searching through some past threads. The filter was cleaned 3 months ago (the pool guy cleans it twice per year).

For example:

| RPM | Watts | GPM | Filter Pressure |

| 1800 | 260 | 16 | 8 |

| 2000 | 360 | 20 | 9 |

| 2350 | 600 | 30 | 11 |

| 2500 | 720 | 33 | 12 |

| 2800 | 1025 | 40 | 14 |

The SWCG needs a minimum GPM (~25 GPM), as does the Hayward suction cleaner in order to be effective (~30+ GPM), as does the Pentair MasterTemp 400 heater (40 GPM minimum according to the manual). I also like to achieve 1 turnover per day (I realize many here say this is not necessary, but 1 turnover a day is basically a given anyway if I run the pump for 16 hours a day for the spillway water feature ambiance effect).

Ideally, I’d love to boost the GPM flow rate so that I can run the pump at lower RPMs and use less electricity. What could be holding us back? Are there issues you see with the way the system is plumbed that could be causing issues? Are the valves set correctly? I'm a bit of a novice at anything equipment-related. Pics attached.

Appreciate any assistance you can offer if there’s something you think we could change that might make a significant difference or more troubleshooting steps you think I should take.

Thanks!

Last edited: