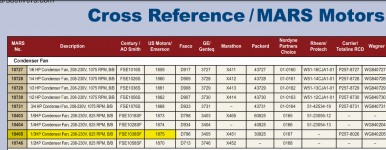

You might be able to find a cross reference from a motor shop.So over $400 is what I should expect for this fan motor?

Pentair Ultratemp 120 Fan stop during start delay

- Thread starter Matthewrehm

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Could you make this work?

Diversitech 1/3HP 1075 RPM Condenser Fan Motor 208-Volt - 230-Volt - 60Hz WG840729 - The Home Depot

These motors install with all standard 48 frame mounting brackets. They are a quiet operator and electrically reversible. There is an Automatic Thermal Overload Protector and they have class B insulation.

www.homedepot.com

Replacing Condenser Fan Motors

Hot weather always brings on a lot of condenser fan motor replacements. Although it is not too difficult to change a condenser fan motor, it is still possible to do it incorrectly. Of course you need a motor that operates at the same voltage, phase, and frequency of the original motor and it should also be the same horsepower. However, I would like to mention a few items to check that I often find techs have overlooked. First, make sure the motor you plan to use is actually designed for a condensing fan motor. Specifically, is it sealed and is it designed for vertical shaft installation (assuming a typical vertical mount, induced draft condenser fan). Motors with air vents on the sides or top should not be used outside. Also, all motors are not rated for vertical shaft installation. Some motors are designed for horizontal shaft mount only because they do not have the necessary thrust bearing to take the downward force against the bearing when the fan pushes air up. Next, is the motor the correct RPM? Some condenser fan motors turn 1075 RPM while others turn around 850 RPM. They are not interchangeable. If you can’t read the label on the old motor, take it apart and look at the number of poles. A 6 pole motor will be a 1075 RPM motor and an 8 pole motor will be an 850 RPM motor. Does the new motor turn in the correct direction? If you cannot see the markings on the old motor, you can tell by looking at the fan blade. First, the cups of the blades should be facing up on an upflow blower. Next, the blade should turn in a direction that allows the lower part of the blade to hit the air first. If the blade turns clockwise looking down on it, this is called clockwise shaft end, or counter clockwise lead end because the lead end rotation is always opposite the shaft end. Some motors specify the rotation looking at the shaft while others specify looking at the opposite end where the leads come out. If you are using a general purpose replacement motor, such as a Rescue Motor, you can change the motor rotation if you need to. Some of these motors use different size capacitors for different horsepower ranges. Make sure the capacitor you are using fits the application. Most likely, the capacitor for the old motor will not be the correct size. Most sealed condenser fan motors have weep holes on the bottom that come plugged with plastic caps. You should remove these when installing the motor. The idea is to let condensation out. The motor will last longer if you open the bottom weep holes. After installing the motor and fan, turn the unit on and then off again to see which way the blade is turning. If it is turning in the wrong direction, change the rotation leads on the motor. Changing the power leads will have no effect. Once you establish that the fan is turning in the correct direction, operate the unit and check the motor amp draw. If it operates close to the manufacturer’s FLA specification for your particular application, you should be good to go.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.