I just installed two Pentair IntellifloFX VSF pumps, replacing two old single speed, 2HP pumps. So far they have been working great, but I have noticed that when I have both running for my spa (they share the same suction line and work in parallel), one of the pumps will cut its wattage from 2200 watts at 3450rpm, to about 1700 watts but still saying 3450 rpm. The other will stay at 2200 watts at 3450 RPM. The flow meter on the pump also shows a big difference between the two, with the one at 2200 watts showing around 65gpm, and the one that cuts its wattage down at around 40gpm.

My old setup with the single speed pumps had an external flow meter and each pump was pushing around 50gpm. So both setups output around 100gpm but now they are not equally split as they were before with the 2hp single speed pumps, even though in both scenarios the pumps are identical. If i turn off the spa, the pump that cuts its wattage down will go back up to 2200 watts at 3450rpm. What could be the cause of this, and will it damage the pumps?

I should also add that in my single speed pump setup, it would consume around 5Kw to run the spa jets. With the intellifloXF's it only consumes around 3.9Kw with the same output (maybe a bit more as the jets seem a bit stronger).

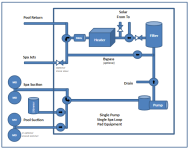

For clarification, the suction line they share is a mirror image "Y", but the outputs are not mirror image. One pump (the "main" pump that filters the pool) goes through the filter and normally returns to the pool. The other pump returns directly to the spa. In spa mode, the main pump has a jandy valve that switches to return to the spa. In this mode they eventually share a common return point to the spa.

My old setup with the single speed pumps had an external flow meter and each pump was pushing around 50gpm. So both setups output around 100gpm but now they are not equally split as they were before with the 2hp single speed pumps, even though in both scenarios the pumps are identical. If i turn off the spa, the pump that cuts its wattage down will go back up to 2200 watts at 3450rpm. What could be the cause of this, and will it damage the pumps?

I should also add that in my single speed pump setup, it would consume around 5Kw to run the spa jets. With the intellifloXF's it only consumes around 3.9Kw with the same output (maybe a bit more as the jets seem a bit stronger).

For clarification, the suction line they share is a mirror image "Y", but the outputs are not mirror image. One pump (the "main" pump that filters the pool) goes through the filter and normally returns to the pool. The other pump returns directly to the spa. In spa mode, the main pump has a jandy valve that switches to return to the spa. In this mode they eventually share a common return point to the spa.

Last edited: