- Mar 14, 2021

- 21

- Pool Size

- 15000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Hi all,

Have ordered the following kit that I hope to receive in the next couple of days:

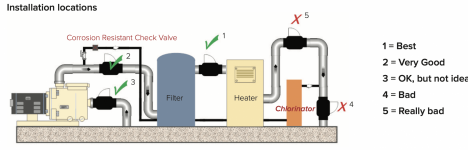

I'm planning on installing it between the heater and diverter valve, removing the current check valve (no point in having 2 in that area?) and feeder and putting in a sweep elbow to improve the flow in that area. I'll make sure the spacing between the SWG and flow meter valve is sufficient based on install instructions. I'll also remove the wiring remnants of the Ozone generator which was removed by previous owner but not fully removed so I no longer have a terminal box hanging off the wall (currently behind the filter).

Here are images of the install area:

Have ordered the following kit that I hope to receive in the next couple of days:

- Pentair IC40 520555 ($600)

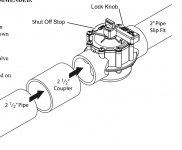

- FlowVis GPM Flow Meter Valve for 2" ($110)

- PVC Schedule 40 2" fittings and piping

- 8 gauge copper grounding wire

I'm planning on installing it between the heater and diverter valve, removing the current check valve (no point in having 2 in that area?) and feeder and putting in a sweep elbow to improve the flow in that area. I'll make sure the spacing between the SWG and flow meter valve is sufficient based on install instructions. I'll also remove the wiring remnants of the Ozone generator which was removed by previous owner but not fully removed so I no longer have a terminal box hanging off the wall (currently behind the filter).

Here are images of the install area: