- Oct 25, 2015

- 5,852

- Pool Size

- 28000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

Thanks much Jim, that helps a lot!Chris,

The difference between an Aux Circuit and a Feature Circuit is that the Aux Circuit has a relay and the Feature Circuit does not.. Pretty simple actually.... If you want to control something that uses 120/220 volts to run, then you will need a relay (aux circuit).. If you want to control something that does not need 120/220 volts, you can use a Feature circuit. Features circuits can be used to control pump speeds or turn valves on/off... Both Aux circuits and Feature circuits can be turned on manually or can be scheduled.

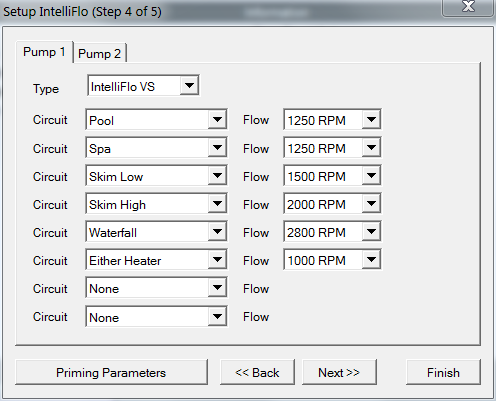

You don't "schedule" a pump.. You scheduled a Circuit and then assign the Circuit name to the pump.. As in... Schedule "Pool" circuit from 8 am until 8 pm and then assign "Pool" circuit to the list of speeds for your pump.. Here is a ScreenLogic shot of my set up. Your set up pages will be different, but the basic idea is the same.. You can see where I have a minimum speed for Pool and then can change the speed based upon which other circuits are on, such as skim low or waterfall circuits..

Once you understand Pentair's logic it really is pretty simple..

Thanks,

Jim R.

Chris