- Jun 8, 2019

- 4,576

- Pool Size

- 20000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

I was getting a 0002 error on my pump, and had to spin the impeller from behind with an Allen wrench to get it to start whenever it stopped. I took it apart, cleaned up some pine needles that had gotten into it, and put it back together. Wife noticed some water leaking, and someone here had recommended I change the shaft seal when I took it apart the first time, so I did. Took it back apart and…the old shaft seal had disintegrated. My pump is a mess inside. >.< Photos:

Old shaft seal:

Inside of the seal plate after I’d taken out the hard ceramic part of the seal:

I scraped out as much as I could of the rubber melted to the seal plate.

Whatever goes behind the seal plate around the shaft was also really damaged.

And the seal plate itself seems all pitted and trashed inside.

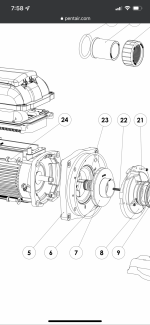

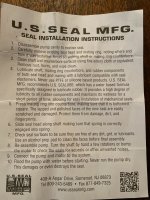

So…pretty sure I’m buying a new seal plate. Probably the impeller too, to be safe. But I can’t find a diagram that includes the piece behind the seal plate that was around the shaft to replace that. Anyone know what that is so I can buy a replacement?

Also I can’t find the replacement parts for this model online. They appear to be for a 342001 and not a 342002, which this one is. Anyone have a bead on that?

Old shaft seal:

Inside of the seal plate after I’d taken out the hard ceramic part of the seal:

I scraped out as much as I could of the rubber melted to the seal plate.

Whatever goes behind the seal plate around the shaft was also really damaged.

And the seal plate itself seems all pitted and trashed inside.

So…pretty sure I’m buying a new seal plate. Probably the impeller too, to be safe. But I can’t find a diagram that includes the piece behind the seal plate that was around the shaft to replace that. Anyone know what that is so I can buy a replacement?

Also I can’t find the replacement parts for this model online. They appear to be for a 342001 and not a 342002, which this one is. Anyone have a bead on that?

Last edited: