I guess a better question might be - assuming I'm ok with the difference in cost (about $30 in this situation), is metallic a better choice than non-metallic? And, if so, should I use the insulated or non-insulated connectors?

Is this stand pipe for a spa blower and would it be good to install one?

- Thread starter dailygenesis

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Turbo1Ton

Gold Supporter

- Dec 26, 2019

- 1,995

- Pool Size

- 14500

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

I would use Liquid Tite non-metallic if it were mine.I guess a better question might be - assuming I'm ok with the difference in cost (about $30 in this situation), is metallic a better choice than non-metallic? And, if so, should I use the insulated or non-insulated connectors?

When you say metallic, you are talking about liquid-tite metallic, correct? If you are using LFMC (liquid-tite flexible metal conduit), then I would recommend the insulated throat connectors.

All of my conduits are non-metallic.

--Jeff

Thank you. Yes I mean liquid tight metallic.I would use Liquid Tite non-metallic if it were mine.

When you say metallic, you are talking about liquid-tite metallic, correct? If you are using LFMC (liquid-tite flexible metal conduit), then I would recommend the insulated throat connectors.

All of my conduits are non-metallic.

--Jeff

Specifically this -> Southwire 1/2 in. x 25 ft. Liquidtight Flexible Metallic Titan Steel Conduit 55082621 - The Home Depot

VS this -> Southwire 1/2 in. x 25 ft. Ultratite Liquidtight Flexible Non-Metallic PVC Conduit 55094221 - The Home Depot

Turbo1Ton

Gold Supporter

- Dec 26, 2019

- 1,995

- Pool Size

- 14500

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

The metallic is much more difficult to work with, especially if you have never used it before. And in my opinion, just not necessary in this application.Thank you. Yes I mean liquid tight metallic.

Specifically this -> Southwire 1/2 in. x 25 ft. Liquidtight Flexible Metallic Titan Steel Conduit 55082621 - The Home Depot

VS this -> Southwire 1/2 in. x 25 ft. Ultratite Liquidtight Flexible Non-Metallic PVC Conduit 55094221 - The Home Depot

--Jeff

All of mine are non-metallic. So much easier to work with. If 6ft all you need - just purchase a premade non-metallic WHIP.Thank you. Yes I mean liquid tight metallic.

Specifically this -> Southwire 1/2 in. x 25 ft. Liquidtight Flexible Metallic Titan Steel Conduit 55082621 - The Home Depot

VS this -> Southwire 1/2 in. x 25 ft. Ultratite Liquidtight Flexible Non-Metallic PVC Conduit 55094221 - The Home Depot

I looked at the whips but I need about 14 feet to run it down to the pad, over to the pipe and up to the blower.All of mine are non-metallic. So much easier to work with. If 6ft all you need - just purchase a premade non-metallic WHIP.

View attachment 535739

I appreciate all of the input, I will likely go with the non-metallic.

Alright so there might be a wrench in the plans. I decided it would be good to try and verify that the pipe is open and actually does send air to the spa before going to all the trouble of installing a blower. The best option I could come up with for a blower to use to try this is my new Ryobi electric leaf blower. It is up to 450 CFM and has a variable speed idle setting. So, I tried attaching that to the pipe, started out at lowest speeds and gradually ramped it up, but I have not been able to get any air out of the spa jets. I even lowered the water level below the jets just to make sure there wasn't any water in the ring (though I suppose it is possible there is water in the pipe underground) and still nothing. I can't find anywhere that air is coming out while my leaf blower is running on this pipe.

I can think of the following possibilities for why this might be happening. I am wondering if anyone could help me figure out the most likely possibilities and if there's anything that can be done about them:

I can think of the following possibilities for why this might be happening. I am wondering if anyone could help me figure out the most likely possibilities and if there's anything that can be done about them:

- Maybe there is water in the pipe underground, and maybe the leaf blower isn't built to push enough pressure to flush that out. The blower doesn't even seem to strain when it is running and I can't feel any leakage around its connection to the pipe, so I'm thinking maybe it has it's own relief system or something so it doesn't push air if it encounters resistance (after all, leaf blowers aren't made to encounter resistance more than just leaves).

- Maybe there is a blockage in the pipe.

- Maybe this pipe isn't supplying air to the spa at all. Is it possible that it is part of a Suction-Limiting Vent System? That is the only other thing I have found that would explain why it is there, but it doesn't seem to be in the right place for that, and also then why would there be a pipe connecting to the top ring of the venturi? I wish I had taken more and better pictures during construction. That was a big oversight on my part!

Put a garden hose in the pipe and see if water comes out at the spa.

Leaf blowers are made for volume, not pressure, so they won't usually generate enough pressure to clear a line with water.

The pump should be on to activate the venturi and you should feel some suction on the pipe when the pump is on and the jets have air coming out.

Maybe put a piece of plastic over the pipe while the jets are on to see if the air stops and if the plastic gets pulled down by the suction.

The pump should be on to activate the venturi and you should feel some suction on the pipe when the pump is on and the jets have air coming out.

Maybe put a piece of plastic over the pipe while the jets are on to see if the air stops and if the plastic gets pulled down by the suction.

- Jul 21, 2013

- 65,118

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

The pic below show that you have air and water looped T'd to the jets.

Do you get any air bubbles with the water when you use the spa?

Do you get any air bubbles with the water when you use the spa?

Your arrow points to the line that probably goes to the equipment pad.

However, there are also 3 lines that probably go to air inlets near the spa.

Do you have air inlets by the spa?

Does air come out when the jets are on?

Your spa returns do not really look like venturi jets.

Can you show the jet nozzles in the spa?

However, there are also 3 lines that probably go to air inlets near the spa.

Do you have air inlets by the spa?

Does air come out when the jets are on?

Your spa returns do not really look like venturi jets.

Can you show the jet nozzles in the spa?

Yes, the jets do produce air bubbles, some better than others. There are two jets that have always been a little problematic in not producing many bubbles. I think this is because those jets sit closer to the wall of the spa and have less pipe between the jet and the spa in which to create the venturi effect. Somehow in construction the gunite circle wall wasn't created perfectly in the center of all the jets and it cheats closer on one side than the other, meaning some jets have a longer distance between the jet and the spa wall and others shorter. I was hoping that adding a spa blower might help with this and just make the bubbles more consistent, etc.The pic below show that you have air and water looped T'd to the jets.

Do you get any air bubbles with the water when you use the spa?

As @JamesW notes, there are also three lines that connect to vents on top of the spa cap (photo below). If you open these vents, the bubbles do increase. If you keep them closed, there are some bubbles, but less.

I have never been able to confirm that air is been sucked into the pipe at the pad when spa is running. I might try the plastic sheet method @JamesW suggested to see if I can confirm any suction out of that pipe.

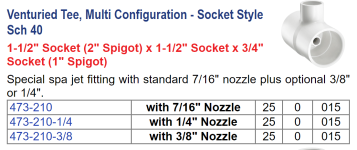

I believe these are the nozzles used. I have pulled them out before and examined them. I don't have any good pics of them in place but I'm pretty sure this is them -> Custom Molded Products Venturi Tee (#7) Nozzle | 23309-000-020Your spa returns do not really look like venturi jets.

Can you show the jet nozzles in the spa?

Yes, although I think they are CMP -> Venturi Tees - CMP but maybe those are all the same just rebranded? The nozzles are threaded and I am pretty sure they are 3/8" orifice.This looks like the type of venturi T that may have been used...

- Jul 21, 2013

- 65,118

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Yup, have someone stand at the pipe by the equipment pad when the spa is running and block off the air pipe intake with a piece of cardboard or plastic or paper plate.

You should see the air bubbles disappear when the pipe is blocked and return when opened.

It sounds to me like your venturi air system is working ok.

You should see the air bubbles disappear when the pipe is blocked and return when opened.

It sounds to me like your venturi air system is working ok.

For ease in determining the proper operation of the venturi tee refer to this chart. It is recommended to base the design of a Spa on the "Rule of Thumb "

One venturi tee for each 10 to 15 GPM's.

Attempting to "push" excessive flow through a venturi tee demands very high system pressures.

https://www.lascofittings.com/venturi-tees

https://www.wildwestpoolsupplies.com/pvc-lasco-1-1-2x1-1-2x3-4-venturi-tee-473-210/

As a designer or contractor of a gunite pool you can be assured the fit of our sockets and spigots will be companion to your other components.

All sockets and spigots comply with ASTM D2466 "Poly(Vinyl Chloride) (PVC) Schedule 40 Socket Type Fittings".

The socket end accepts a standard IPS pipe or fitting internally; whereas the spigot is identical diameter to IPS pipe.

Test results show the Westlake Pipe & Fittings Venturi Tee will provide superior action in use.

This relates directly to the volume of air which is drawn into the jet stream.

This combination results in the ACTION your customer wants.

The Westlake Pipe & Fittings nozzle has been designed to eliminate changes when used with additional jets.

http://63.156.201.111/smcweb/EINM02...22&SrchStrng=473-210-1/4&Rndm=128189505#PS021

http://63.156.201.111/SMC/SCHDL40FTTNGS_PS-1.htm#PS021

Last edited:

It is difficult to tell which brand of T you have.

Maybe Spears, Lasco, CMP, Waterway etc.

The nozzles are probably interchangeable for some models.

Try putting a garden hose into the pipe at the equipment pad to see if water comes out at the jets.

Maybe Spears, Lasco, CMP, Waterway etc.

The nozzles are probably interchangeable for some models.

Try putting a garden hose into the pipe at the equipment pad to see if water comes out at the jets.

I just ran the spa with pump at 100% with all three of the vents on the spa cap closed. The jets all produce a good, solid stream of bubbles, except for the two jets I mentioned earlier. And that is with the vents closed. But while this is happening, I went back to the pipe at the pad and I feel no suction at all on that pipe. I put a piece of cling wrap over the top and there is no movement, not even the slightest bit of being sucked into the pipe. I took some video of all of this but I'm trying to figure out how to best share that.Yup, have someone stand at the pipe by the equipment pad when the spa is running and block off the air pipe intake with a piece of cardboard or plastic or paper plate.

You should see the air bubbles disappear when the pipe is blocked and return when opened.

It sounds to me like your venturi air system is working ok.

So, I agree the venturi system seems to work, but I'm not yet convinced that pipe at the pad is playing any part in that. And if not, then why? What is it for? And from where is the spa getting air when all the vents are closed?

Try putting a garden hose into the pipe at the equipment pad to see if water comes out at the jets.

Yeah, my guess is CMP only because my PB used mostly CMP and Hayward products everywhere else.It is difficult to tell which brand of T you have.

Maybe Spears, Lasco, CMP, Waterway etc.

The nozzles are probably interchangeable for some models.

Try putting a garden hose into the pipe at the equipment pad to see if water comes out at the jets.

With the garden hose - should I drain the spa down below the jets before trying this?

I will work on that but it will probably be later as other non-pool-related duties call. I really appreciate everyone's help working through this.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.