- Dec 5, 2016

- 108

- Pool Size

- 21500

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

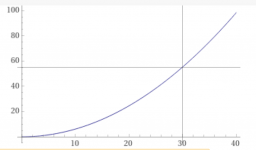

I'm finally getting around to adding the "fun" bits of my pool-- and one of the things I wanted to do is have the ability to hook up a garden hose into a PVC contraption so that my kids could have a "build a fountain" playkit on the sun shelf. I had extra threaded returns on a separate pipe from the pad added for this purpose, but now that I'm trying to set it up, I am realizing that the intelliflo just doesn't have enough head to get water 30' through a garden hose at a rate that is useful.

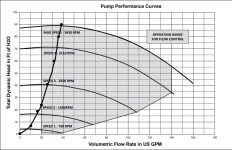

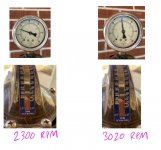

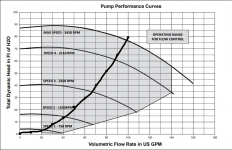

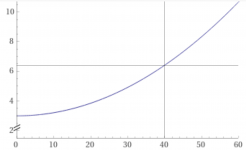

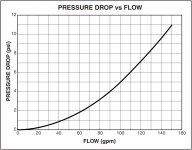

What I think I need is essentially a booster pump for a pressure side cleaner-- the oft quoted up to 50psi at ~15GPM feels very much like the low end of house water pressure and that seems to get through hoses just fine. Pentair doesn't seem to make an 'intelligent' booster though. I'd like to be able to dial in just the right amount of flow using screenlogic for the thing I'm doing so I'm not just running a 1HP pump and then restricting flow somehow with a valve or pressure relief assembly. Are any of the intelli* pumps higher head, or is this a fool's errand?

What I think I need is essentially a booster pump for a pressure side cleaner-- the oft quoted up to 50psi at ~15GPM feels very much like the low end of house water pressure and that seems to get through hoses just fine. Pentair doesn't seem to make an 'intelligent' booster though. I'd like to be able to dial in just the right amount of flow using screenlogic for the thing I'm doing so I'm not just running a 1HP pump and then restricting flow somehow with a valve or pressure relief assembly. Are any of the intelli* pumps higher head, or is this a fool's errand?