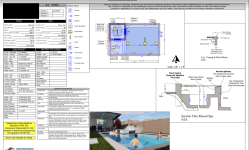

The challenge I’m having is that the look we were going for is having the Baja steps span the connection between pool wall and spa wall.

But I also know that I don’t want a super shallow end. So I’m caught between having to change the design and look of the pool to accommodate the depth I want, or forego the depth to get the look. The only compromising choice available it seems is to add the second step off the Baja which will cut into the usable space of the Baja but at least accommodate the 4ft depth.

But I also know that I don’t want a super shallow end. So I’m caught between having to change the design and look of the pool to accommodate the depth I want, or forego the depth to get the look. The only compromising choice available it seems is to add the second step off the Baja which will cut into the usable space of the Baja but at least accommodate the 4ft depth.