Maybe the top step sticks out of the water due to the waterline issue and have another return at a level to keep water flowing on the step surface at a reduced flow.

HELP!!!!! ET Abducted my Pool Builder!!!!!

- Thread starter I Got This!!!!!!

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

phonedave

Well-known member

- May 30, 2012

- 2,243

- Pool Size

- 17000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Turbo Cell (T-CELL-5)

Maybe the top step sticks out of the water due to the waterline issue and have another return at a level to keep water flowing on the step surface at a reduced flow.

He wants to do that, but he has a limited space to work with

"I thought to put 3 or 4 small return fittings into the last riser but as you can see in the picture there is only 4" of space and

a standard return fitting is way to close to the step and j channel. I'm looking for a smaller return that would use a total of 2 1/2"or 2 3/4 max."

Maybe he can make something work with a 2" spa jet housing

CMP 2" Typhoon Twist-Lock Jet Housing

CMP Typhoon 200 Series Jet Body/Housing. Accepts CMP 2" face, Typhoon Twist-Lock (snap-in) non-threaded jet internal inserts. 23422-000-000

and maybe a cyclone jet, so it washes over the step, as opposed to shoots across it.

Pentair 2" Euro Cyclone Swirl Twist-Lock Spa Jet Insert

Pentair Euro Cyclone Swirl Twist-Lock (snap-in) Jet Internal Insert. Features a rotational nozzle with a textured gray 5-point scalloped face. 900147WW

Honestly I would correct this issue now. The liner can be amended for a fee amd the steps moved or altered. I've done it before not too expensive overall. You will fight this for the rest of the pools life amd every liner will look like Crud in just a few years bleached out by the suns UV amd dry up quick. Now is the time to deal with this and just pull the bandaid one shot deal. He should know better and eat it. Maybe even offer a little help its gonna coat you way more over the years. Just my professional opinion

phonedave

Well-known member

- May 30, 2012

- 2,243

- Pool Size

- 17000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Turbo Cell (T-CELL-5)

Honestly I would correct this issue now. The liner can be amended for a fee amd the steps moved or altered. I've done it before not too expensive overall. You will fight this for the rest of the pools life amd every liner will look like Crud in just a few years bleached out by the suns UV amd dry up quick. Now is the time to deal with this and just pull the bandaid one shot deal. He should know better and eat it. Maybe even offer a little help its gonna coat you way more over the years. Just my professional opinion

I am still not understanding how the liner got made this way in the first place. The stair was built incorrectly, then the liner company made the liner, and then the liner company tells the owner that the step is incorrect.

Why would they not tell the owner BEFORE making the liner.

I agree, don't monkey around. Fix the step, and then get a new/modified liner.

I can’t modify the steps, was looking for alternative solutions. ThanksI'm not sure I'm getting this. You mention the liner is on order how can you modify steps? how will the liner work/fit the step area?

I'm not sure I'm getting this. You mention the liner is on order how can you modify steps? how will the liner work/fit the step area?

Update!!!!!!!Hi All, So here is my story....

I hired a PB in January and it took him till mid May to start digging.

Last I saw him was the end of July and all I have to show for it is steel walls and concrete.

I'm guessing he was abducted by aliens!!!!!! I hope they take me next so I can get my hands on the guy!!

I've re filed the permits under my name so now I'm the GC, plumber, electrician, and donkey for the job.

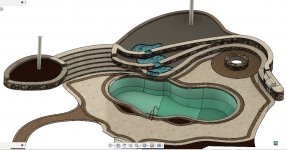

Anyway, here's about my pool.... or at least what I want.

20x40 free form vinyl lined with liner over the steps

4' shallow with 6' deep end.

21000 gallons with about 750 sq ft surface

My Hayward equipment list is as follows..and only because my last pool used Hayward....

vs950 pump

360sx side mount multi valve sand filter

chlorinator for tablets

400K nat gas heater

I will have 2 skimmers and a main drain set, along with 5 returns and a waterfall.

All the equipment sits basically level with the water line level. The water fall is to be

pumped up 48" above the water line level.

I am running all home runs and figure I will need about 450/500 ft of 2" pvc sh 40 solid pipe.

Id like to use 2 1/2" by the equipment because the equipment can handle it and I was thinking

it would make the flows merge instead of yielding.

Here is where I need help...

I'll need 40 90s and 30 45s. So to help reduce flow restriction Id like to use sweep 90s

but the sweep 90s at lowes are listed as sh40 but under drainage......

With the parameters i mentioned do I need the sweep 90s????

Are the 90 sweeps from lowes ok to use?

Second problem....

The PB made the steps wrong and now the liner company said the top step will be above the water level

which will dry rot the vinyl prematurely. Also because there is no water on the step the vinyl might pull away from the wall.

I thought to put 3 or 4 small return fittings into the last riser but as you can see in the picture there is only 4" of space and

a standard return fitting is way to close to the step and j channel. I'm looking for a smaller return that would use a total of 2 1/2"or 2 3/4 max.

If I cant find a return fitting to work the only other option I can think of is to have a piece of sandstone cut and shaped like the step and have all

the edges bullnosed and set it on a bed of silicone on the top step...... And they wonder why I drink!!!!! LOL

Any suggestions will be welcomed

Thanks

I decided to go with multiple returns that will keep the water on the step and keep the liner in its place.

Thanks

Attachments

phonedave

Well-known member

- May 30, 2012

- 2,243

- Pool Size

- 17000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Turbo Cell (T-CELL-5)

Update!!!!!!!

I decided to go with multiple returns that will keep the water on the step and keep the liner in its place.

Thanks

It is only going to keep water on the step while it is running. Or are you running your pump 24/7 ?

It just seems like a lot of work, plumbing, expense, and maintenance down the road instead of getting the step and liner corrected.

Hey Dave, will be running pump at least during the day to keep the liner with water from the direct sunlight. Thanks for the input.It is only going to keep water on the step while it is running. Or are you running your pump 24/7 ?

It just seems like a lot of work, plumbing, expense, and maintenance down the road instead of getting the step and liner corrected.

You can modify the steps. That's a days demo amd a day to re frame them and pour. PB is getting away with murder on this one

I agree. Water running on the steps isn't the way it should end up being and frankly I'm not convinced it'll keep it from fading. Demo and re frame and order the liner for the new.You can modify the steps. That's a days demo amd a day to re frame them and pour. PB is getting away with murder on this one

phonedave

Well-known member

- May 30, 2012

- 2,243

- Pool Size

- 17000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Turbo Cell (T-CELL-5)

You can modify the steps. That's a days demo amd a day to re frame them and pour. PB is getting away with murder on this one

His PB skipped town already and left him in this situation, so the cost is going to be on the owner. Still, it should be corrected.

I still do not understand how the liner company made the liner and then told him about the step being too high. You would think they would have told him that before they made the liner in the first place.

The liner company doeant tell you anything. They receive measurement and make a liner they dont care where the stairs are.

phonedave

Well-known member

- May 30, 2012

- 2,243

- Pool Size

- 17000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Turbo Cell (T-CELL-5)

The liner company doeant tell you anything. They receive measurement and make a liner they dont care where the stairs are.

Normally that is what I would expect. Just like ordering anything that needs measurements (like kitchen cabinets - don't get me started), you supply the measurements and they built it to however you tell them you need it.

However, this is what the OP said in the original post

Second problem....

The PB made the steps wrong and now the liner company said the top step will be above the water level

which will dry rot the vinyl prematurely. Also because there is no water on the step the vinyl might pull away from the wall.

Which makes it seem like the liner company knew there would be an issue with the height of the step.

Probably just recycling what PB told them. They are assuming the skimmer location is standard and going off of that otherwise. A spillover pool wouldn't have a problem here but rare

Hey guys,

I hate to bother you with a question that Im sure has been asked a million times.

Im getting confused with all the gpm, curves, thd, and flow rates.....

If someone could take a few minutes to look over what I have and direct me Id be extremely grateful.

I have a 21000 gallon free form pool 20x40 ish.

1 waterfall

2 skimmers

4 returns

4 drains( T'd from 2 pipes}

400+FT of 2" pipe

48 90s

21 45s

11 22s

17 Ts

16 couplers

The equipment pad is 25 feet to the closest point of the pool.

I wanted to turn the water over 3 times a day in 12 hours or less.

I ran home runs to the pad from each point so I have 9 -2" pipes

up at the equipment pad. My thinking was if a line went bad I could just shut it down and still have a fully functional pool.

I'm planning on using 2 1/2" pipe to make the manifolds and join the equipment.

I was thinking about using the Hayward tristar 950vs and the s360sx sand filter with a 400k gas heater.

The pump and heater support 2 1/2" pipe but the filter only goes up to 2".

Should I make a bypass to relive the filter of too much flow? Maybe split off the pump and have one pipe go to the filter and the

other go to the waterfall.

Also the heater can take the 2 1/2" pipe but not the full flow or gpm from the pump... does this need a bypass as well????

I assume Ill need extra valves to do this? IM SO CONFUSED!!!!!! lol

So more info to help understand....

I'm thinking the 950vs because of the waterfall.

I'm thinking the sand filter because I had a hot tub with cartages and that was gross cleaning it to me . I had a DE filter years ago and all I remember is reading all the warnings on the bag, sounded like a way for a company not to take responsibility for something they know is bad for you....!!!

Thanks for any help, I'm the guy who's pool builder was abducted by aliens and am trying to get this finished.

I hate to bother you with a question that Im sure has been asked a million times.

Im getting confused with all the gpm, curves, thd, and flow rates.....

If someone could take a few minutes to look over what I have and direct me Id be extremely grateful.

I have a 21000 gallon free form pool 20x40 ish.

1 waterfall

2 skimmers

4 returns

4 drains( T'd from 2 pipes}

400+FT of 2" pipe

48 90s

21 45s

11 22s

17 Ts

16 couplers

The equipment pad is 25 feet to the closest point of the pool.

I wanted to turn the water over 3 times a day in 12 hours or less.

I ran home runs to the pad from each point so I have 9 -2" pipes

up at the equipment pad. My thinking was if a line went bad I could just shut it down and still have a fully functional pool.

I'm planning on using 2 1/2" pipe to make the manifolds and join the equipment.

I was thinking about using the Hayward tristar 950vs and the s360sx sand filter with a 400k gas heater.

The pump and heater support 2 1/2" pipe but the filter only goes up to 2".

Should I make a bypass to relive the filter of too much flow? Maybe split off the pump and have one pipe go to the filter and the

other go to the waterfall.

Also the heater can take the 2 1/2" pipe but not the full flow or gpm from the pump... does this need a bypass as well????

I assume Ill need extra valves to do this? IM SO CONFUSED!!!!!! lol

So more info to help understand....

I'm thinking the 950vs because of the waterfall.

I'm thinking the sand filter because I had a hot tub with cartages and that was gross cleaning it to me . I had a DE filter years ago and all I remember is reading all the warnings on the bag, sounded like a way for a company not to take responsibility for something they know is bad for you....!!!

Thanks for any help, I'm the guy who's pool builder was abducted by aliens and am trying to get this finished.

Some plumbing gurus will be along shortly, but there is no harm in possibly over sizing a 3HP VS pump and lowering it to fit your needs. Or adding a second if enough features warrant it.

Turnover is a myth. One ‘turnover’ nets 65% of the water through the filter due to mixing, and only that high under perfect circumstances. The second ‘turnover’ maybe hits 85% and each subsequent turnover raises the achievement rate by less. You pool needs the amount of skimming / filtering that it needs. It will even change throughout the season needing more in the spring and fall, and less In the middle. Your pool will tell you what it needs at any point in time. Listen to it, not some preconceived (and false) one size fits all notion.

DE is as harmless as cement, which you also shouldn’t huff the dust from. Small particles get trapped in the lungs and it’s easily avoidable with some reasonable care. The same goes with Chlorine and Muriatic acid. Both are caustic so don’t bathe in them or suck in the vapors and you’ll be fine.

Turnover is a myth. One ‘turnover’ nets 65% of the water through the filter due to mixing, and only that high under perfect circumstances. The second ‘turnover’ maybe hits 85% and each subsequent turnover raises the achievement rate by less. You pool needs the amount of skimming / filtering that it needs. It will even change throughout the season needing more in the spring and fall, and less In the middle. Your pool will tell you what it needs at any point in time. Listen to it, not some preconceived (and false) one size fits all notion.

DE is as harmless as cement, which you also shouldn’t huff the dust from. Small particles get trapped in the lungs and it’s easily avoidable with some reasonable care. The same goes with Chlorine and Muriatic acid. Both are caustic so don’t bathe in them or suck in the vapors and you’ll be fine.

Hi guys, I posted this yesterday but it was moved to a different section. Being I had limited replies I thought to try reposting it again today.

Hey guys,

I hate to bother you with a question that Im sure has been asked a million times.

Im getting confused with all the gpm, curves, thd, and flow rates.....

If someone could take a few minutes to look over what I have and direct me Id be extremely grateful.

I have a 21000 gallon free form pool 20x40 ish.

1 waterfall

2 skimmers

4 returns

4 drains( T'd from 2 pipes}

400+FT of 2" pipe

48 90s

21 45s

11 22s

17 Ts

16 couplers

The equipment pad is 25 feet to the closest point of the pool.

I wanted to turn the water over 3 times a day in 12 hours or less.

I ran home runs to the pad from each point so I have 9 -2" pipes

up at the equipment pad. My thinking was if a line went bad I could just shut it down and still have a fully functional pool.

I'm planning on using 2 1/2" pipe to make the manifolds and join the equipment.

I was thinking about using the Hayward tristar 950vs and the s360sx sand filter with a 400k gas heater.

The pump and heater support 2 1/2" pipe but the filter only goes up to 2".

Should I make a bypass to relive the filter of too much flow? Maybe split off the pump and have one pipe go to the filter and the

other go to the waterfall.

Also the heater can take the 2 1/2" pipe but not the full flow or gpm from the pump... does this need a bypass as well????

I assume Ill need extra valves to do this? IM SO CONFUSED!!!!!! lol

So more info to help understand....

I'm thinking the 950vs because of the waterfall.

I'm thinking the sand filter because I had a hot tub with cartages and that was gross cleaning it to me . I had a DE filter years ago and all I remember is reading all the warnings on the bag, sounded like a way for a company not to take responsibility for something they know is bad for you....!!!

Hey guys,

I hate to bother you with a question that Im sure has been asked a million times.

Im getting confused with all the gpm, curves, thd, and flow rates.....

If someone could take a few minutes to look over what I have and direct me Id be extremely grateful.

I have a 21000 gallon free form pool 20x40 ish.

1 waterfall

2 skimmers

4 returns

4 drains( T'd from 2 pipes}

400+FT of 2" pipe

48 90s

21 45s

11 22s

17 Ts

16 couplers

The equipment pad is 25 feet to the closest point of the pool.

I wanted to turn the water over 3 times a day in 12 hours or less.

I ran home runs to the pad from each point so I have 9 -2" pipes

up at the equipment pad. My thinking was if a line went bad I could just shut it down and still have a fully functional pool.

I'm planning on using 2 1/2" pipe to make the manifolds and join the equipment.

I was thinking about using the Hayward tristar 950vs and the s360sx sand filter with a 400k gas heater.

The pump and heater support 2 1/2" pipe but the filter only goes up to 2".

Should I make a bypass to relive the filter of too much flow? Maybe split off the pump and have one pipe go to the filter and the

other go to the waterfall.

Also the heater can take the 2 1/2" pipe but not the full flow or gpm from the pump... does this need a bypass as well????

I assume Ill need extra valves to do this? IM SO CONFUSED!!!!!! lol

So more info to help understand....

I'm thinking the 950vs because of the waterfall.

I'm thinking the sand filter because I had a hot tub with cartages and that was gross cleaning it to me . I had a DE filter years ago and all I remember is reading all the warnings on the bag, sounded like a way for a company not to take responsibility for something they know is bad for you....!!!

If your waterfall is an open pipe to a rock waterfall you can most likely avoid going through the filter. So just tee off of the pipe outlet and put a valve to either flow to the filter or to the waterfall. You can set it up to have dual flow (just one valve on the line to the waterfall) or independent flow (a valve on the line to the filter and a valve on the line to the waterfall where you open one and close the other depending on which you want to flow). Some water features have very small openings and require you to go through a filter to prevent clogging at the water feature exit.Should I make a bypass to relive the filter of too much flow? Maybe split off the pump and have one pipe go to the filter and the

other go to the waterfall.

One other idea, since you have 2 pipes coming from the drains is to have a separate pump to run the waterfall where it has it own suction and return. Again, that is if you do not need to go through a filter. This is how I set up my waterfall as it is just an 2inch pipe exiting over a rock waterfall.

Consider a heater bypass if you wish to reduce flow restrictions.

Heater Bypass - Further Reading

Since you have a VS pump, I wouldn't worry about turnover. Just run it longer at lower rpm which saves energy and provides continuous circulation.

You do not indicate you have a spa. Please post a drawing of your pool and current plumbing layout if you have that available.

Hi Herman,

Thanks for the reply....

The waterfall is basically a pipe spilling into the first of a set of 3 "ponds" cascading over to each other before spilling into the pool. I say ponds but they will be simple shallow depressions lined with pond liner and fitted to the spillways. So I think I like this idea because pad space is limited. There is no spa. Ill try to upload pictures and a video showing the pipes work. I laid out the equipment area , its not set in stone because I haven't figured it all out yet.

youtube link

Thanks for the reply....

The waterfall is basically a pipe spilling into the first of a set of 3 "ponds" cascading over to each other before spilling into the pool. I say ponds but they will be simple shallow depressions lined with pond liner and fitted to the spillways. So I think I like this idea because pad space is limited. There is no spa. Ill try to upload pictures and a video showing the pipes work. I laid out the equipment area , its not set in stone because I haven't figured it all out yet.

Attachments

Last edited:

- May 3, 2014

- 62,735

- Pool Size

- 6000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Those will be an algae breeding ground. Best to configure a waterfall that does not 'store' any water when off.first of a set of 3 "ponds"

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.

![IMG_9606[7367].jpg](/data/attachments/201/201029-ba1850bd968576ac3544d1d22192a413.jpg)