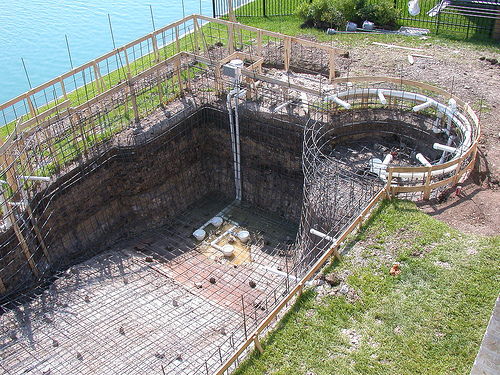

Hi--Noob here. What's the easiest/cheapest way to bond an already-installed slide (Interfab Wild Ride) to our pool? Pool and slide was installed by previous owner in 2009 and is an in-ground fiberglass shell. Slide mounts via anchor bolts into the concrete--the metal slide legs slide over the mounts (see pic).

Not sure how best to find and tap into the equipotential grid or if it's even necessary. Do all four legs of the slide need to be bonded? How about the metal railing up along the slide's steps? All pump and electrical equipment are located inconveniently far from the slide.

Thanks in advance!

Not sure how best to find and tap into the equipotential grid or if it's even necessary. Do all four legs of the slide need to be bonded? How about the metal railing up along the slide's steps? All pump and electrical equipment are located inconveniently far from the slide.

Thanks in advance!

helps out.

helps out.