Hi folks,

I'm a homeowner in San Diego. When my WhisperFlo failed in 2006, I purchased and installed an IntelliFlo #011012. It's been doing great until a couple days ago when I was doing some work on the house's main electrical panel. I noticed later that the pump's display is completely dead, even when disconnected from the IntelliTouch control system. The pump is not coming on at all.

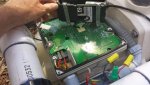

I disassembled the drive unit. No water incursion but a small blackened area on top of the printed circuit board. My hunch is a blown capacitor, but they seem to be embedded in plastic resin so can't be accessed or replaced.

Any suggestions on next steps? Is there anyone who can repair these units? Pentair tells me the drive #350104 can be replaced by #353251, which looks to be $600 online and would only have a 60-day parts warranty. An entire #011018 pump is under $900, but does that have a 3-year warranty if self-installed? Replacing the entire pump would be a big job due to tight plumbing. I assume I could replace the drive, or the drive + motor, and leave the existing plumbing and basket?

Thanks,

Mark

I'm a homeowner in San Diego. When my WhisperFlo failed in 2006, I purchased and installed an IntelliFlo #011012. It's been doing great until a couple days ago when I was doing some work on the house's main electrical panel. I noticed later that the pump's display is completely dead, even when disconnected from the IntelliTouch control system. The pump is not coming on at all.

I disassembled the drive unit. No water incursion but a small blackened area on top of the printed circuit board. My hunch is a blown capacitor, but they seem to be embedded in plastic resin so can't be accessed or replaced.

Any suggestions on next steps? Is there anyone who can repair these units? Pentair tells me the drive #350104 can be replaced by #353251, which looks to be $600 online and would only have a 60-day parts warranty. An entire #011018 pump is under $900, but does that have a 3-year warranty if self-installed? Replacing the entire pump would be a big job due to tight plumbing. I assume I could replace the drive, or the drive + motor, and leave the existing plumbing and basket?

Thanks,

Mark