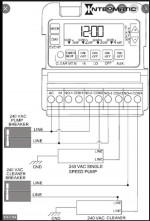

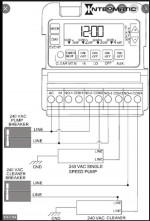

Hello everyone. I am trying to figure out the proper electrical connection in order for the SWG to work in both low and high pump speeds. It currently only turns on with in high speed. My pool timer is the intermatic P1403 and it is currently wired as follows:

Terminal 1 = Hot wire coming from main breaker and a jumper from Terminal 1 to Terminal 3

Terminal 2 = Hot wire coming from main breaker and a jumper from Terminal 2 to Terminal 7

Terminal 3 (Labeled NO-1) = Jumper from Terminal 1 and a jumper from Terminal 3 to Terminal 5

Terminal 4 (Labeled COM 1) = Blue cable coming from pump and black cabled coming from SWG

Terminal 5 (Labeled NO-2) = Jumper from terminal 3

Terminal 6 (Labeled COM 2) = Black cable coming from pump

Terminal 7 (Labeled NO-3) = Jumper from Terminal 2 and second black cable coming from SWG

Terminal 8 (Labeled COM 3) = Red cable coming from pump

Terminal 9 (Labeled NO-4) = This is AUX and is empty

Terminal 10 (Labeled COM 4)= This is AUX and is empty

Yesterday I tested the following:

1. Placed the black cable from SWG that was going into COM 1 over AC terminal 1

2. I moved second cable from SWG that was on No-3 over to Aux com 4.

3. I placed a jumper from AC Terminal 2 over to Terminal 9 No-4. This allowed for SWG to work in low and high. The only thing I didn’t like is that when SWG control box turned on it had a hard start noise. I decided to move all cables back how they were. Not sure if that’s a normal noise but it did work in both speed.

My goal is to get the SWG working in both speeds. The SWG control box is set for 240. Any recommendations on how to achieve this, let me know. Thank you

Terminal 1 = Hot wire coming from main breaker and a jumper from Terminal 1 to Terminal 3

Terminal 2 = Hot wire coming from main breaker and a jumper from Terminal 2 to Terminal 7

Terminal 3 (Labeled NO-1) = Jumper from Terminal 1 and a jumper from Terminal 3 to Terminal 5

Terminal 4 (Labeled COM 1) = Blue cable coming from pump and black cabled coming from SWG

Terminal 5 (Labeled NO-2) = Jumper from terminal 3

Terminal 6 (Labeled COM 2) = Black cable coming from pump

Terminal 7 (Labeled NO-3) = Jumper from Terminal 2 and second black cable coming from SWG

Terminal 8 (Labeled COM 3) = Red cable coming from pump

Terminal 9 (Labeled NO-4) = This is AUX and is empty

Terminal 10 (Labeled COM 4)= This is AUX and is empty

Yesterday I tested the following:

1. Placed the black cable from SWG that was going into COM 1 over AC terminal 1

2. I moved second cable from SWG that was on No-3 over to Aux com 4.

3. I placed a jumper from AC Terminal 2 over to Terminal 9 No-4. This allowed for SWG to work in low and high. The only thing I didn’t like is that when SWG control box turned on it had a hard start noise. I decided to move all cables back how they were. Not sure if that’s a normal noise but it did work in both speed.

My goal is to get the SWG working in both speeds. The SWG control box is set for 240. Any recommendations on how to achieve this, let me know. Thank you